Polycrystalline silicon grading method and system and thin film transistor making method and system

A technology of thin film transistors and polysilicon, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as uneconomical time and cost, inability to determine the crystal state of polysilicon films, and difficulty in evaluating polysilicon films, etc., to achieve improvement The effect of manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

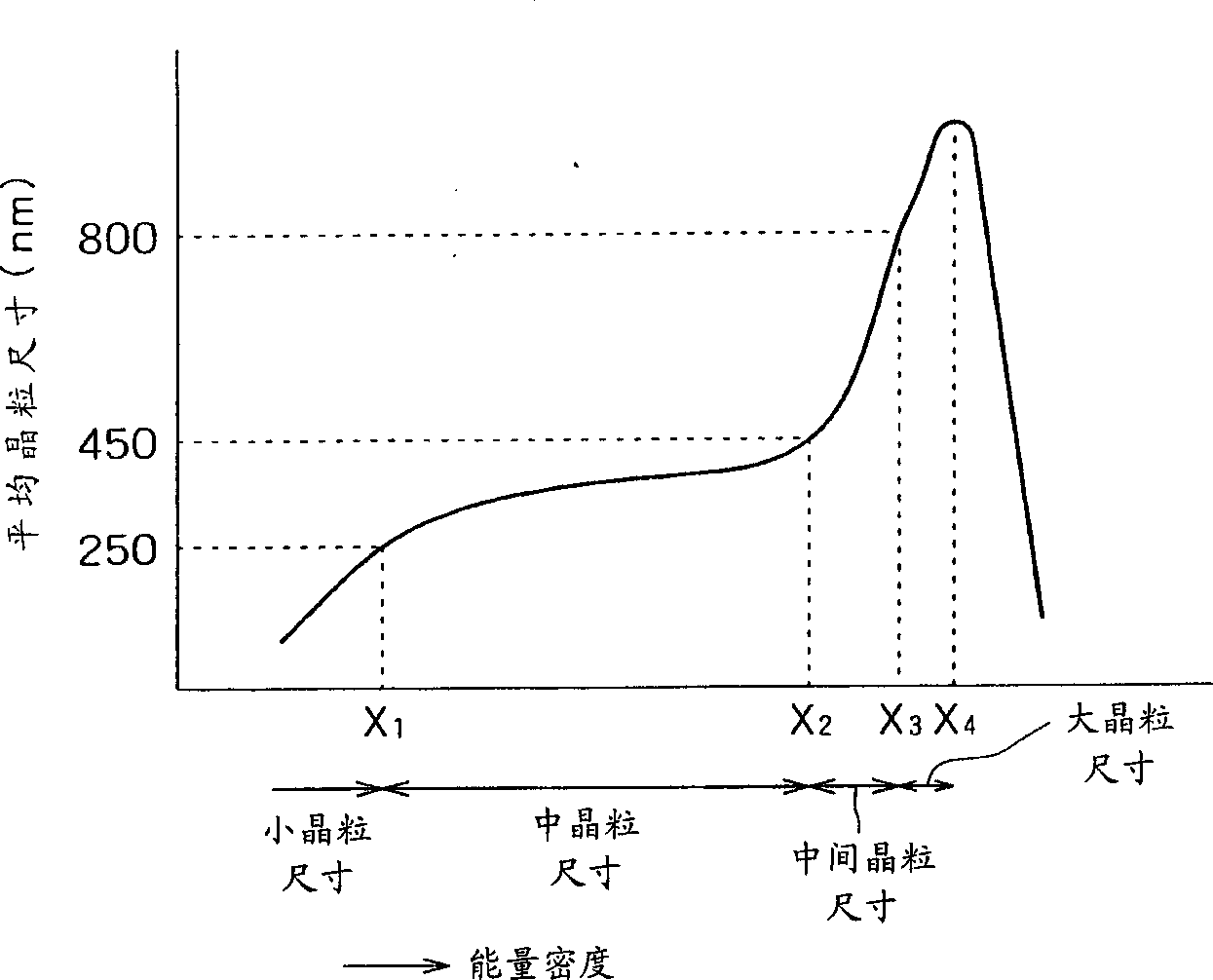

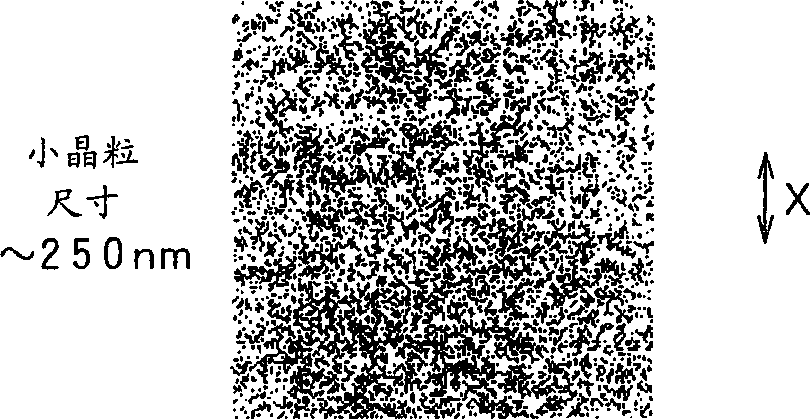

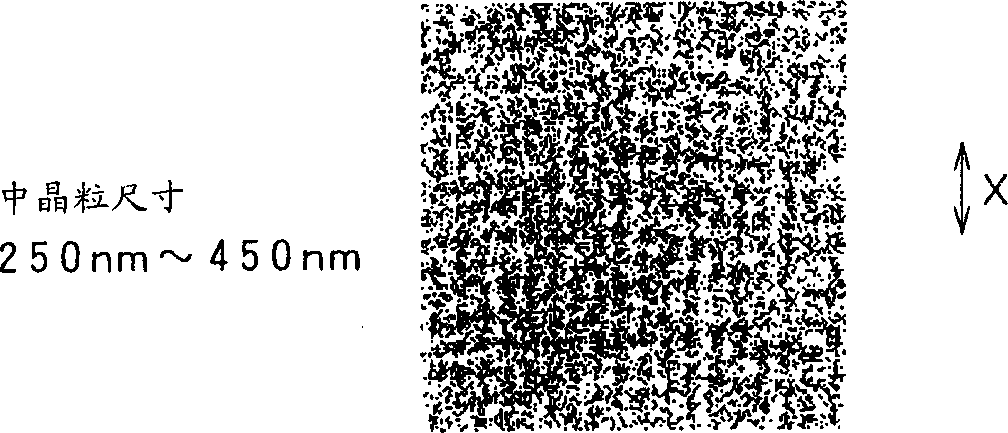

[0040] Hereinafter, preferred embodiments of a polysilicon film evaluation system and a polysilicon film evaluation method according to the present invention, and a thin film manufacturing system using the polysilicon film evaluation system and a thin film manufacturing method using the polysilicon film evaluation method will be described with reference to the accompanying drawings.

[0041] A polysilicon film evaluation system according to an embodiment of the present invention is generally used to inspect a polysilicon film formed in the process of manufacturing a thin film transistor having a top gate structure (hereinafter referred to as "top gate type TFT"). For example, a top-gate type TFT is constituted by stacking a polysilicon film (channel layer), a gate insulating film, and a gate electrode in this order from the substrate side on a glass substrate. In other words, in a top gate type TFT, a polysilicon film functioning as a channel layer is formed at the lowest layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com