Energy-storing multifunctional welding machine

A multi-functional, energy storage technology, applied in the direction of energy storage discharge welding, welding power supply, etc., can solve the problems of large volume, single function, large reactive power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

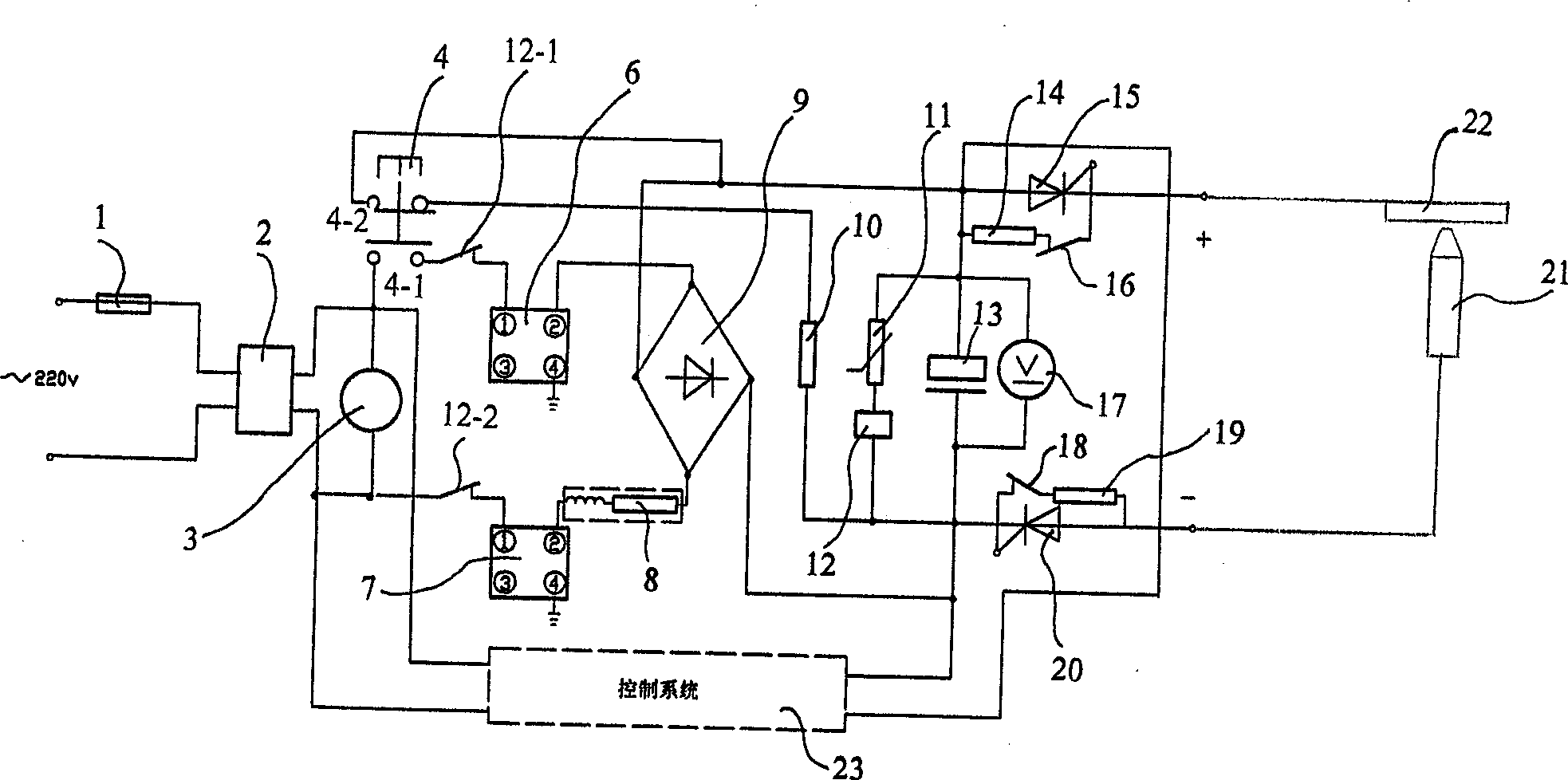

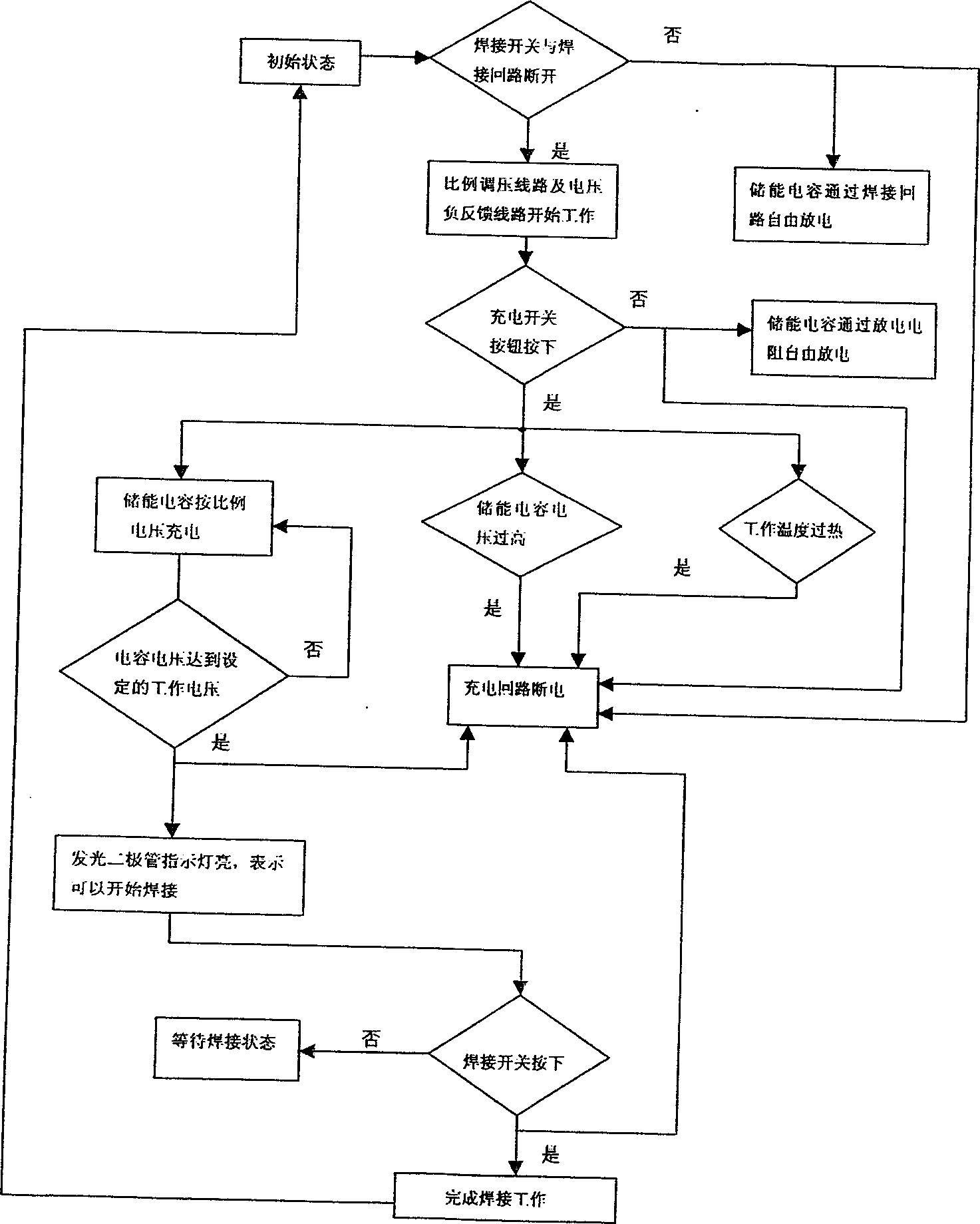

[0028] The following is attached Figure 1-7 Examples further describe the present invention in detail.

[0029] The basic principle of the present invention is as figure 1 shown. It includes fuse 1, leakage protector 2, cooling fan 3, charge and discharge switch 4, thermal element 5 (in figure 2 In the control system), proportional voltage regulation AC zero-crossing solid state relay 6, charging relay (also AC zero-crossing solid state relay) 7, current limiting transient resistor 8, rectifier bridge 9, discharge resistor 10, pressure sensitive element 11 , Overvoltage protection relay 12, energy storage capacitor bank 13, trigger pole bias resistors 14, 19, thyristors 15, 20, trigger relay contacts 16, 18, control system 23, voltage display 17, welding torch 21, workpiece 22.

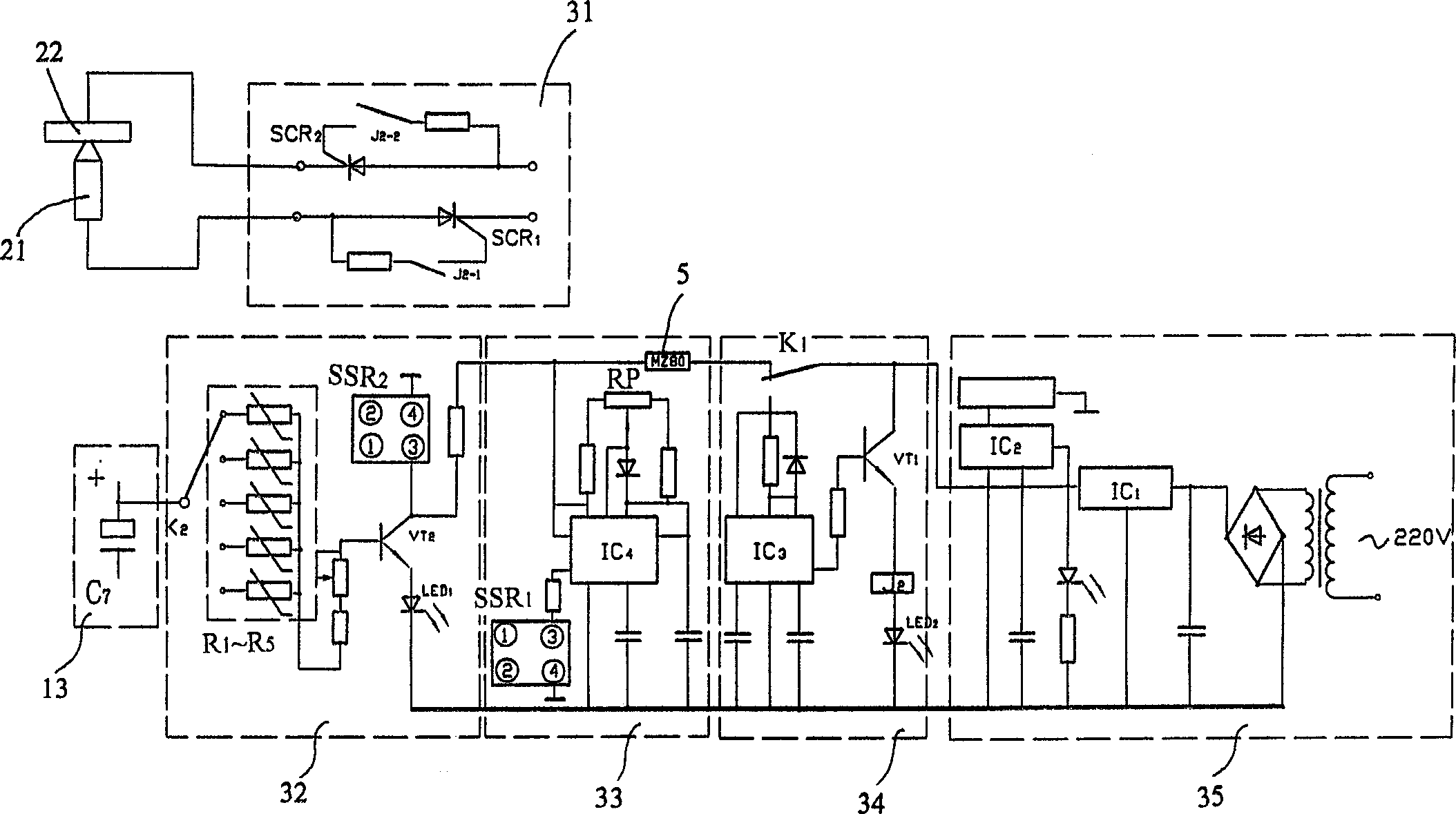

[0030] The main frame of the energy storage type multifunctional welding machine of the present invention (see figure 2) includes an energy storage capacitor bank 13, a welding output circuit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com