Method for single layer or multilayer coextruding two-way extension polypropylene film and special equipment

A polypropylene film, multi-layer co-extrusion technology, applied in the field of polypropylene film manufacturing, can solve the problems of uncontrollable shrinkage rate without high temperature setting, inability to use ultra-low temperature heat-sealing materials, and high energy consumption for product production, so as to improve bag making. Speed and heat sealing strength and sealing appearance quality, solving the problem of longitudinal Young's modulus and transverse balance, and solving the effect of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

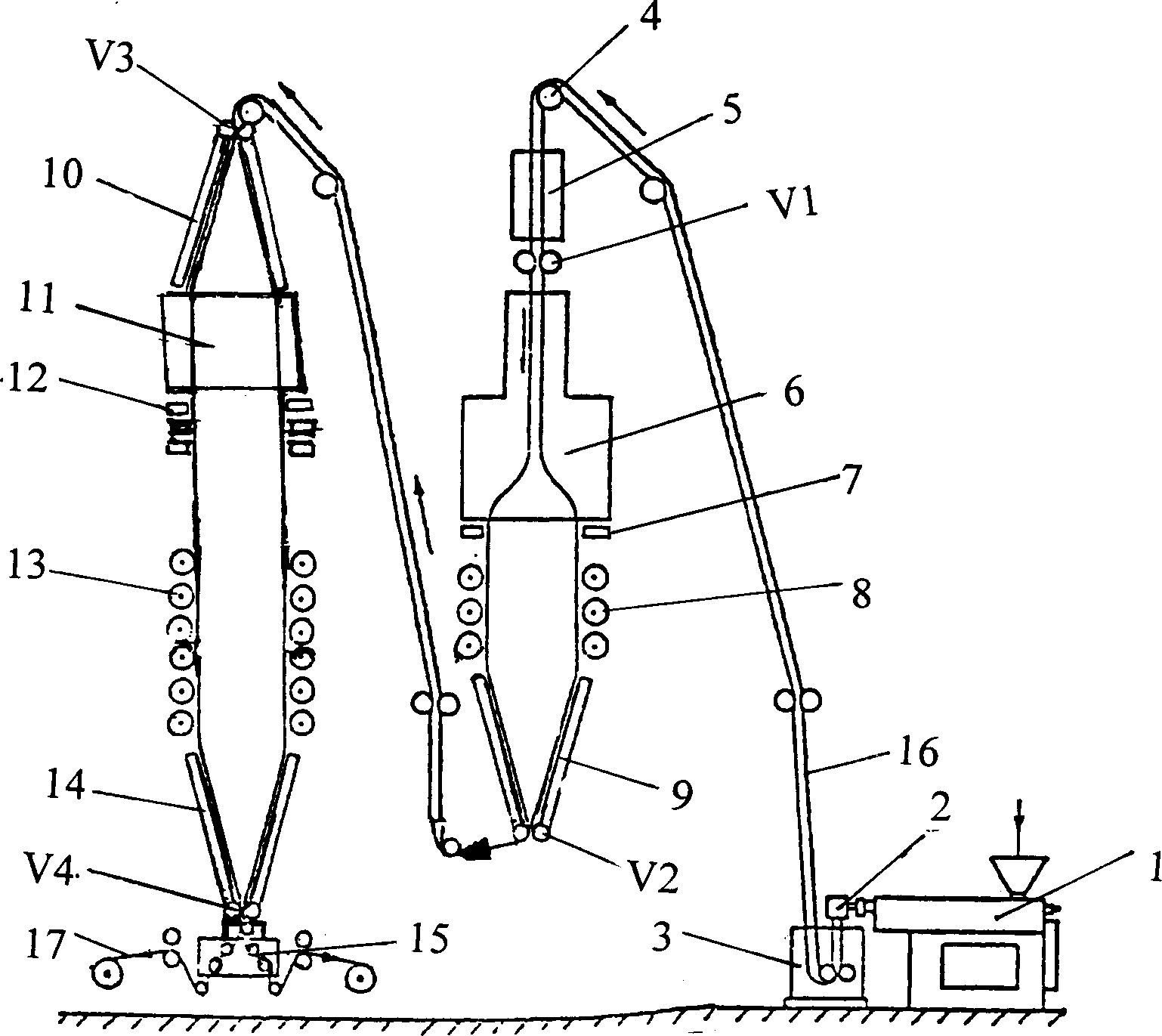

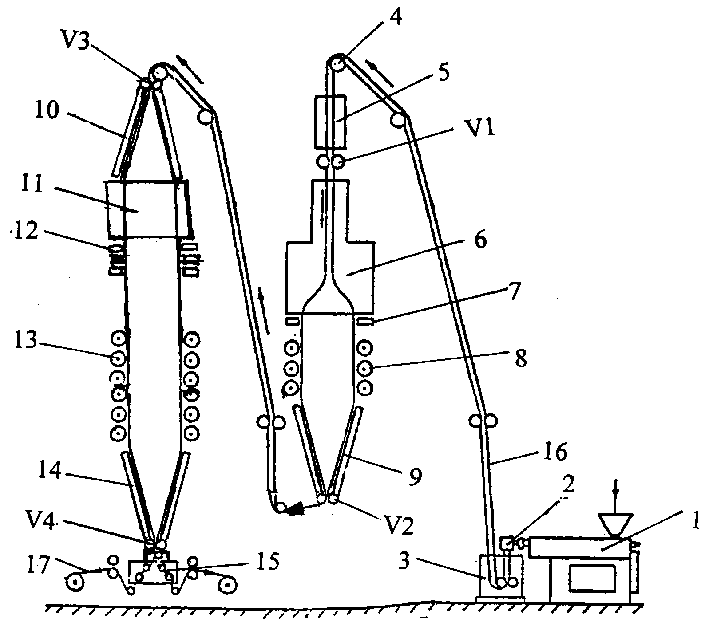

[0033] The film-making method and special equipment adopted in this embodiment can process the following polypropylene films:

[0034] Heat-sealing film: cigarette packaging film, candy packaging film, pearlescent film, ring-shaped label shrink film, overlapping heat-sealing shrink film with vertical and horizontal shrinkage ratio greater than 50%.

[0035] Non-heat-sealing film: printing film, plastic / plastic composite film, paper / plastic composite film, adhesive tape film, etc.

[0036] The width of the product is 1100mm, and the output is 1000 tons / year.

[0037] The process steps of film making are:

[0038] 1) The main extruder plasticizes homopolypropylene, and the plasticizing temperature is 220-280°C; the auxiliary extruder A / C plasticizes copolymerized polypropylene, and the plasticizing temperature is 210-280°C, and the main extruder passes through the planetary Filters and auxiliary machines flow into the inner-cooled flexible self-adjusting ring head through supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com