Methyl acetate hydrolysis process and its equipment

A technology of methyl acetate and process, applied in the field of methyl acetate hydrolysis process and equipment, can solve the problems of catalyst particles falling off, inconvenient catalyst replacement and activation, and troublesome catalyst package manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

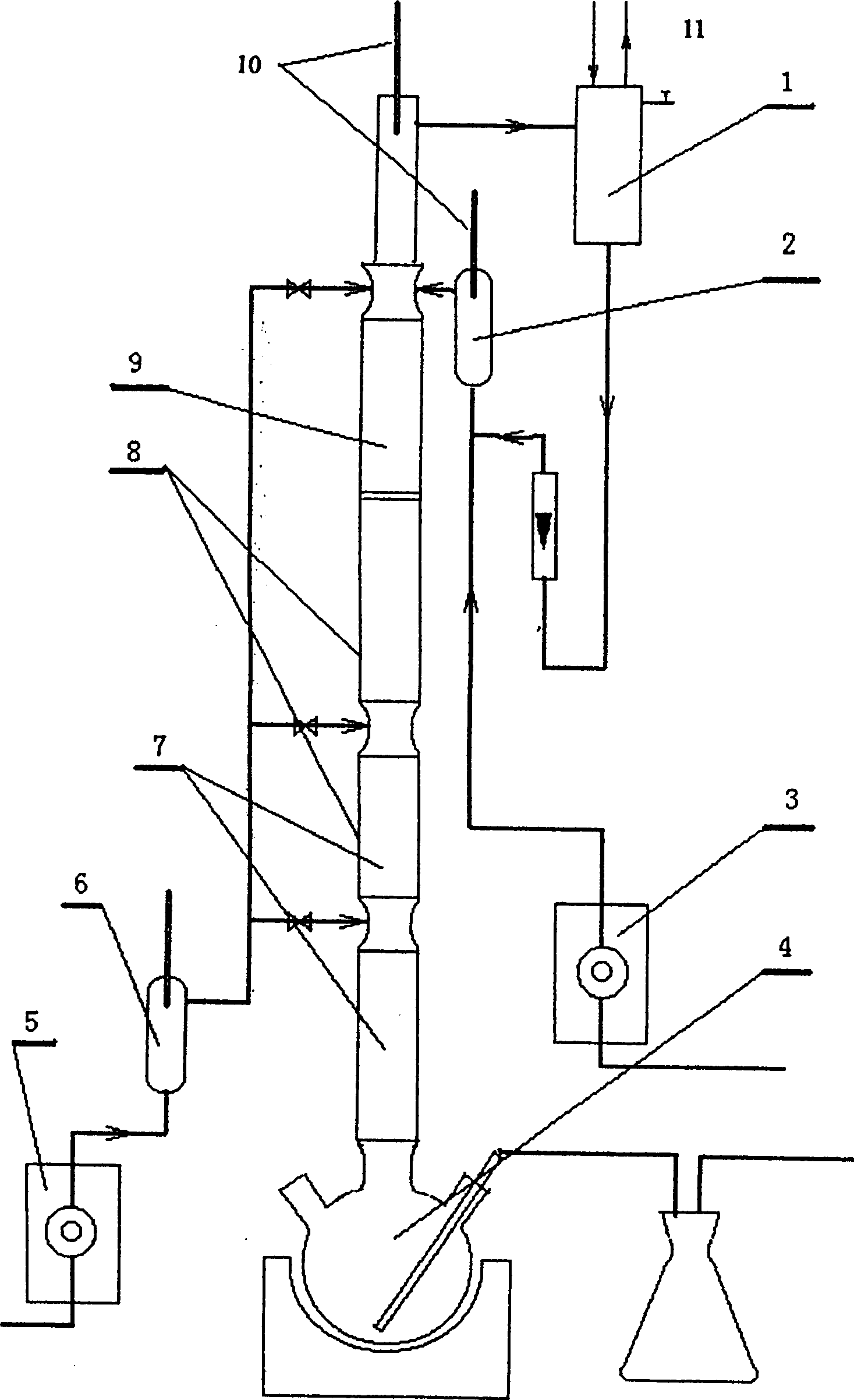

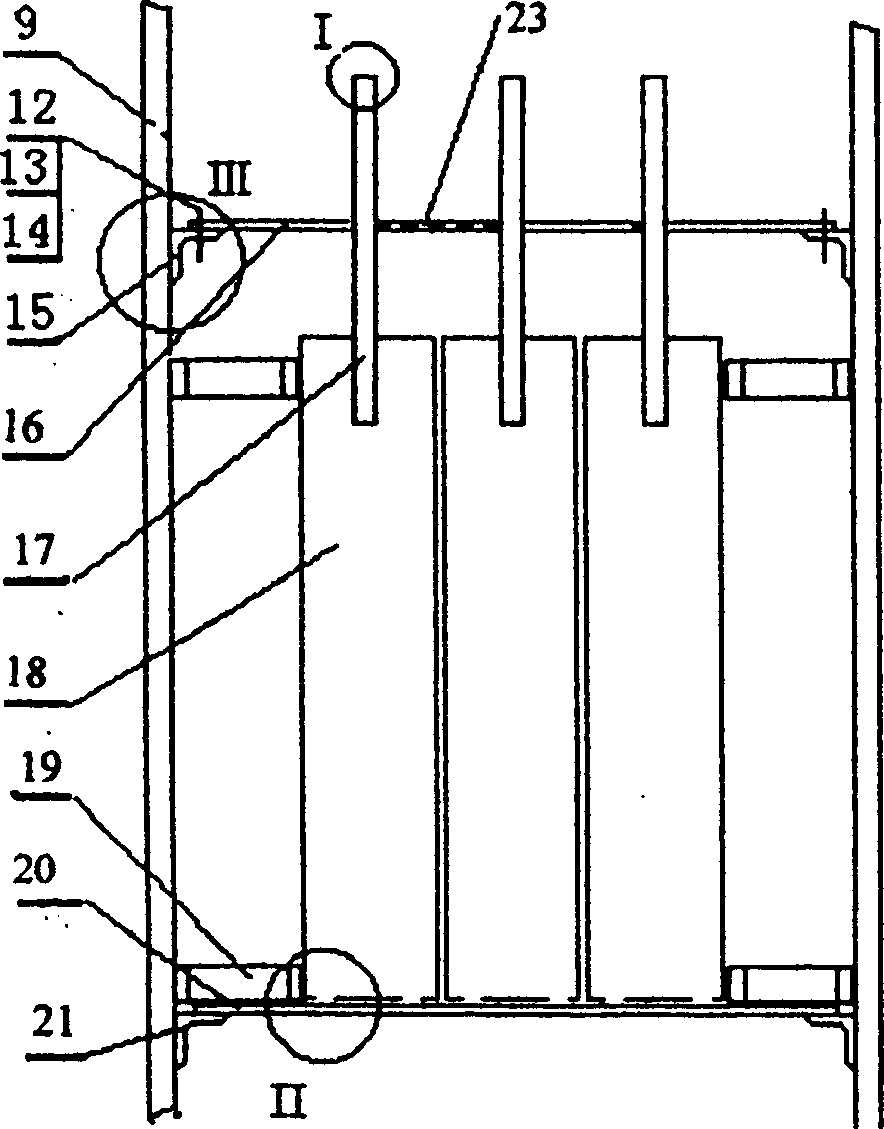

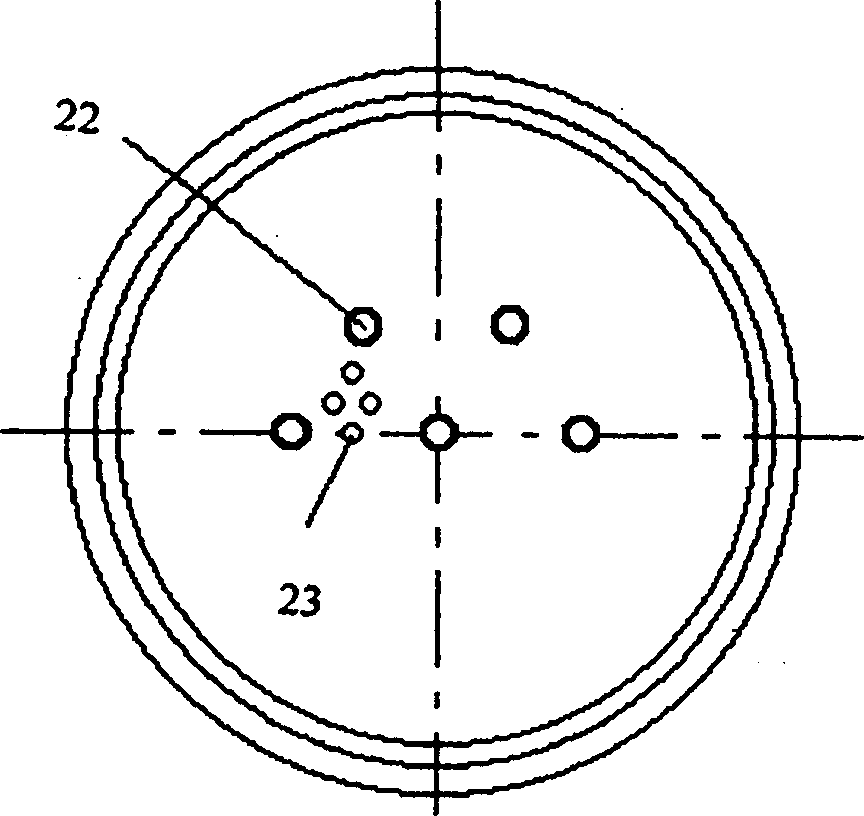

[0012] The specific operation process of the methyl acetate hydrolysis process is: the methyl acetate or the mixture of methyl acetate and methanol measured according to the ratio is continuously transported to the second preheater 6 through the second metering pump 5 and heated to a predetermined temperature from the top of the hydrolysis tower or The bottom of the reaction rectification section of the hydrolysis tower or the middle part of the stripping section of the hydrolysis tower is sent into the hydrolysis tower, and the metered water is continuously sent to the first preheater 2 by the first metering pump 3 to be heated to a predetermined temperature and enters the hydrolysis from the top of the tower Tower, the hydrolysis reaction is carried out in the reaction zone. The reaction product is separated by rectification in the tower, and the volatile components (mainly methyl acetate) are condensed by the condenser 1 at the top of the tower, and the condensate is mixed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com