DC arc plasma equipment and process for preparing micron-class and nano-class powder material

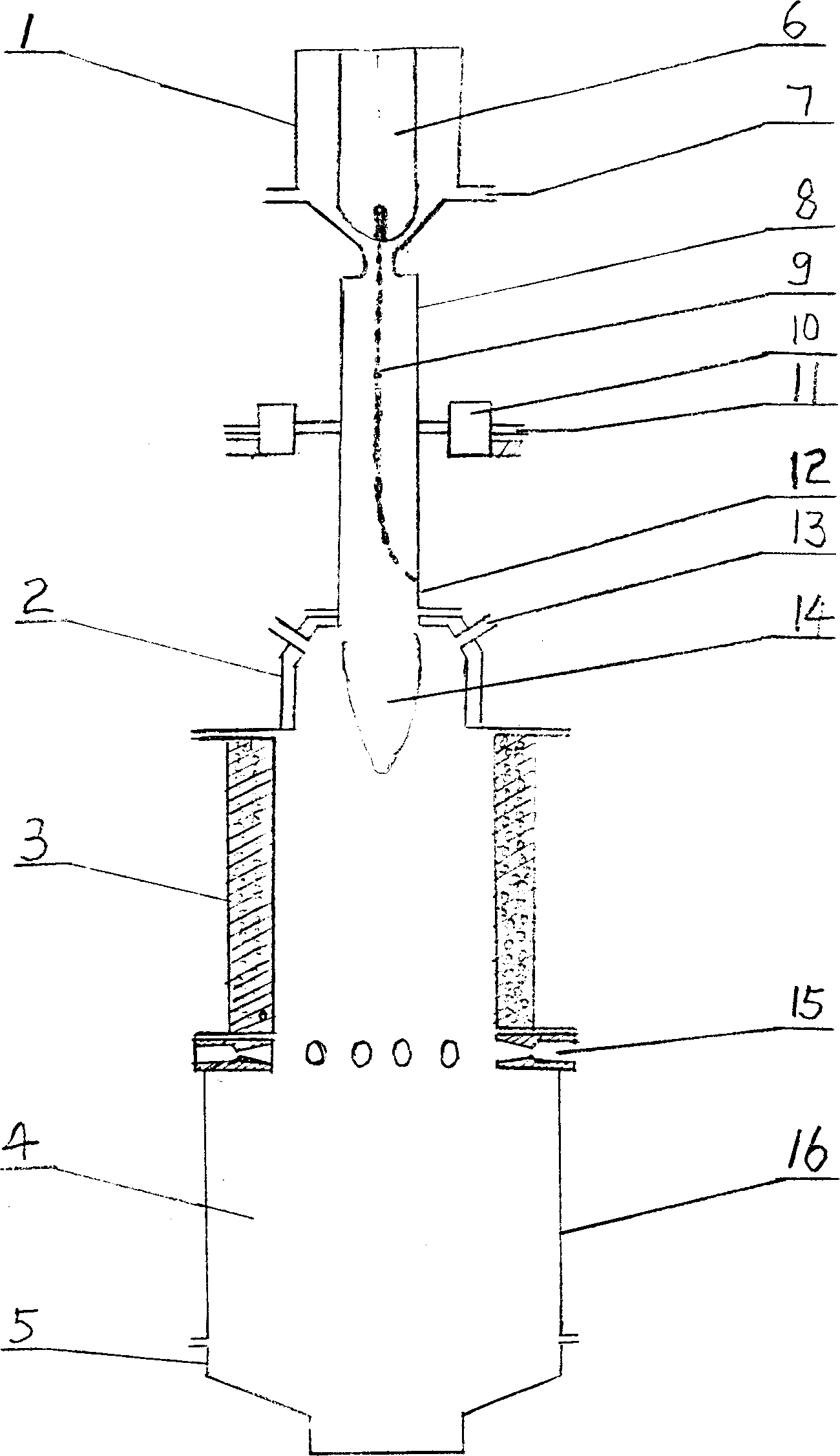

A technology of nanoscale powder and plasma, which is applied in the field of devices for spherical micron and nanoscale powder materials, which can solve problems such as short service life, inability to control particle size well, and inability to realize industrial scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

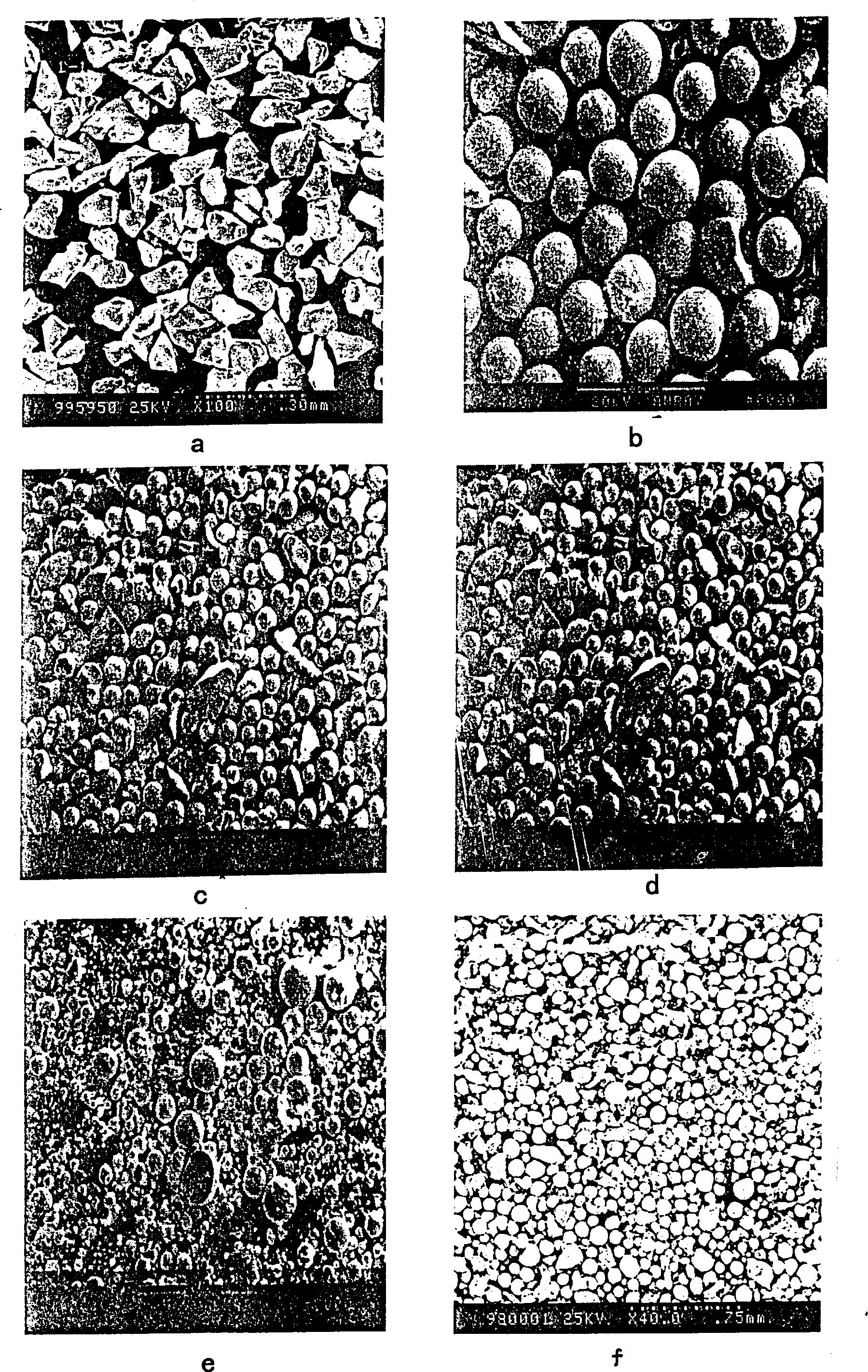

Embodiment 1

[0036] to U 3 Si 2 As raw material, melt U with direct current arc argon-helium (main gas) plasma flame of the present invention 3 Si 2 The fine powder is quenched by the quencher, and collected by gravity sedimentation, cyclone separator and bag dust collector to obtain spherical U 3 Si 2 The finished product has a spheroidization rate of 85-95%, and the feeding rate is 3 kg / hour. See figure 2 , where a is the U obtained by mechanical pulverization 3 Si 2 Powder, b, c, d, e and f are U prepared by the device of the present invention 3 Si 2 Powder.

Embodiment 2

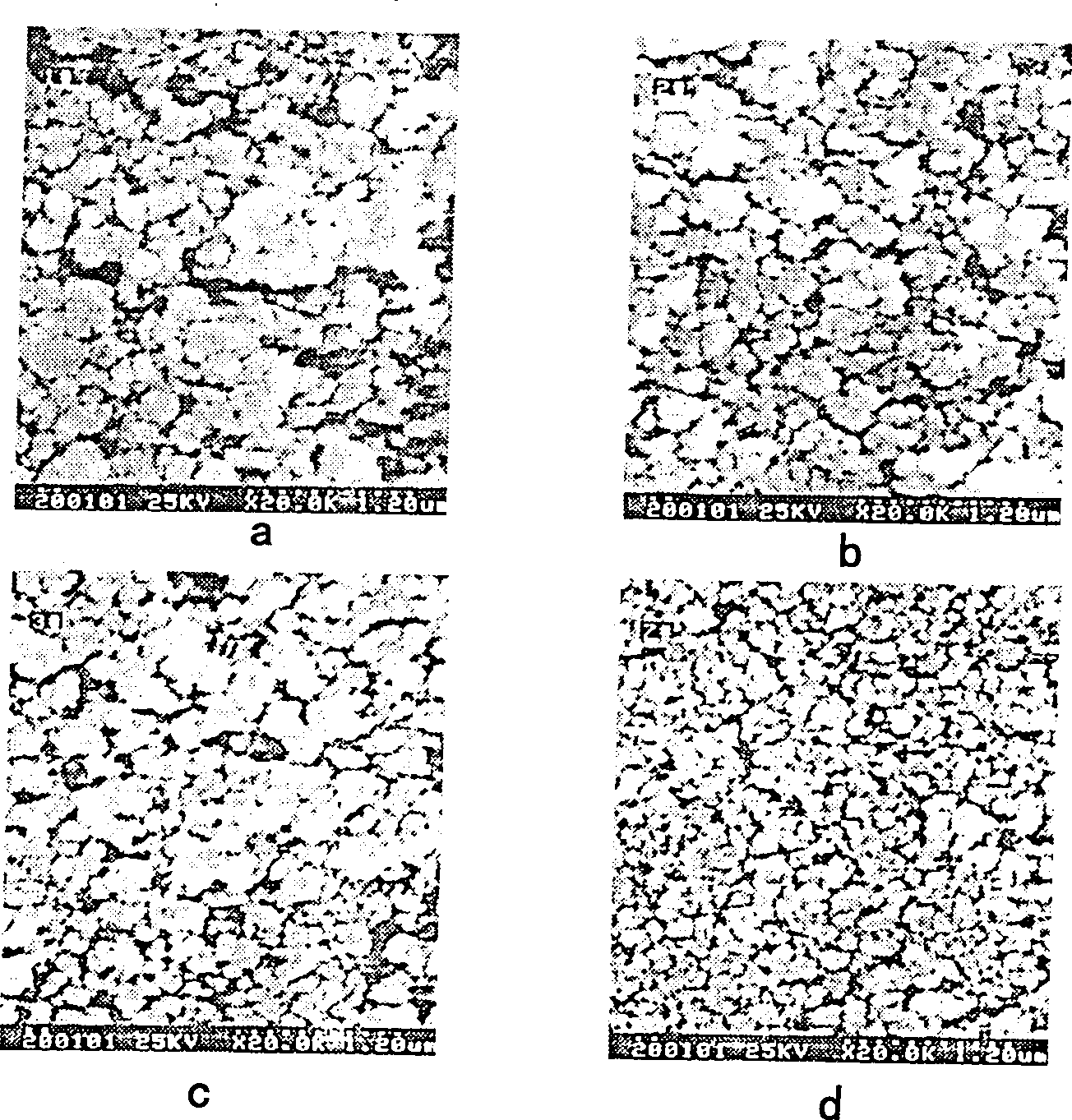

[0038] with Sb 2 o 3 The raw material is melted and vaporized by DC arc nitrogen (main gas) plasma flame, quenched by a quencher, collected by a cyclone separator and a bag dust collector, and the finished product is obtained, with an annual output of 500-1000 tons. See image 3 a, b, c and d, showing that the device of the present invention obtained 30-60 nm Sb 2 o 3 of powder materials.

Embodiment 3

[0040] SiO 2 As raw material, it is melted and vaporized by nitrogen (main gas) plasma flame, quenched by wall quencher and supersonic nozzle, collected by gravity, cyclone separator and bag dust collector to obtain finished products, and to prepare micron and nanoscale Spherical SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com