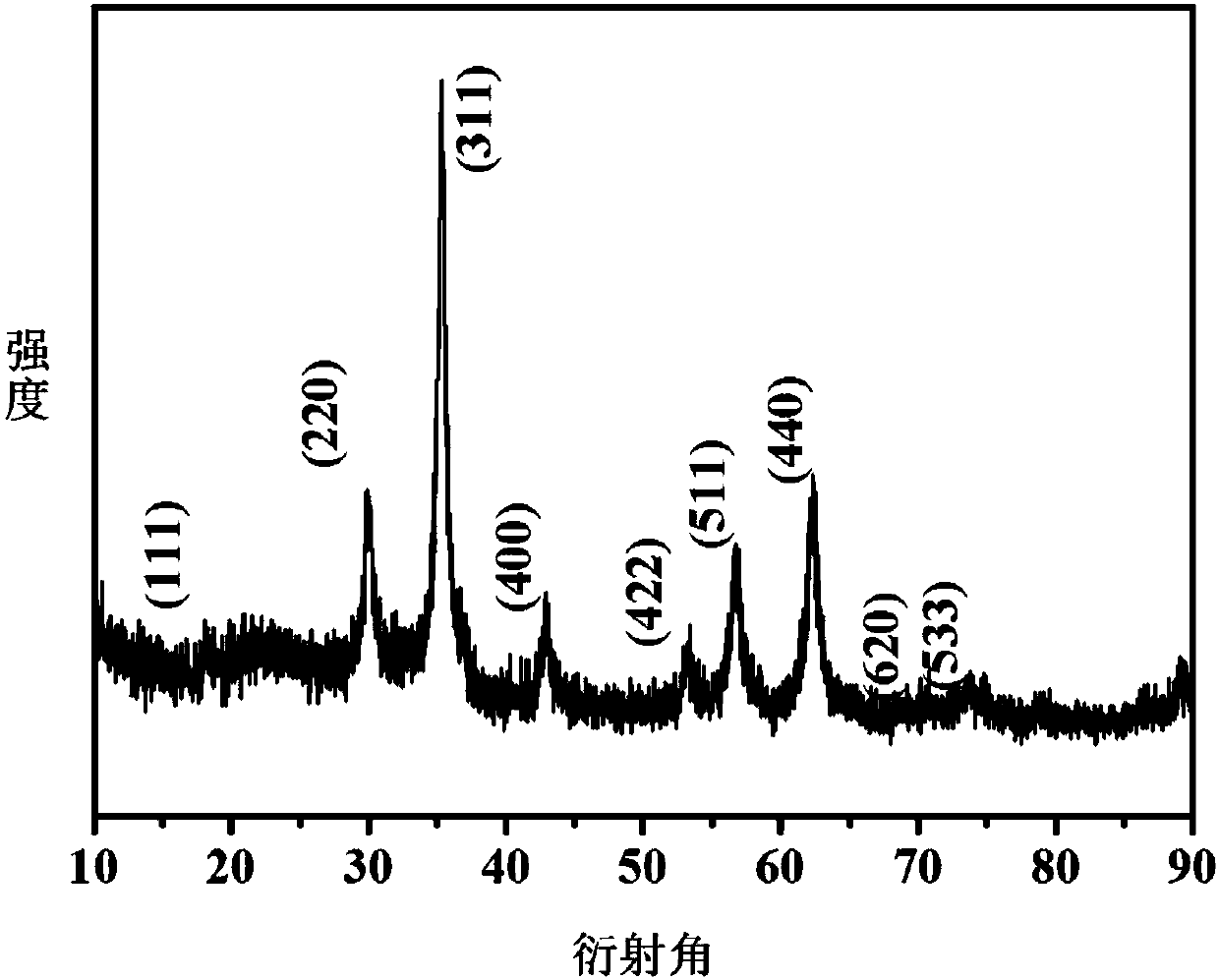

Shuttle-shaped zinc ferrite/carbon lithium ion battery nanometer composite negative electrode material and preparation method and application thereof

A lithium-ion battery and nanocomposite technology, applied in the field of electrochemistry, can solve the problems of too fast specific capacity decay, poor conductivity, low theoretical capacity, etc., and achieve the effects of improving cycle stability, easy process control, and improving rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 1.8571 g of fumaric acid (C 4 h 4 o 4 , 99.0 %) was added to 20 mL of dimethylformamide (HCON(CH 3 ) 2 , AR), after 2 hours of magnetic stirring and mixing at a rate of 750 rpm, a transparent dispersion was obtained. Then weigh 0.4040g ferric nitrate (Fe(NO 3 ) 3 9H 2 O, 98.5%) and 0.1487 g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 99.0%) was added to the above-mentioned dispersion liquid, stirred at the same speed of 750 rpm for 3 hours, mixed evenly, transferred to a 50 mL sealed steel shell of a hydrothermal kettle, and heated in an electric constant temperature blast drying oven at 100 °C The reaction was carried out at the temperature for 12 h. After cooling down to room temperature, the hydrothermal reaction product was separated from solid and liquid, and the obtained solid was washed twice with absolute ethanol, then once with dimethylformamide, and finally twice with absolute ethanol. The washing process is all realized by centrifugation at 8000 r...

Embodiment 2

[0048] (1) Weigh 1.8571 g of fumaric acid (C 4 h 4 o 4 , 99.0 %) was added to 20 mL of dimethylformamide (HCON(CH 3 ) 2 , AR), after stirring and mixing at 750 rpm for 3 hours, a transparent dispersion was obtained. Then weigh 0.8080 g ferric nitrate (Fe(NO 3 ) 3 9H 2 O, 98.5%) and 0.2974 g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 99.0%) was added to the above-mentioned dispersion liquid, stirred at the same speed of 750 rpm for 3 hours, mixed evenly, transferred to a 50 mL sealed steel shell of a hydrothermal kettle, and heated in an electric constant temperature blast drying oven at 100 °C The reaction was carried out at the temperature for 10 h. After cooling down to room temperature, the hydrothermal reaction product was separated from solid and liquid, and the obtained solid was washed twice with absolute ethanol, then once with dimethylformamide, and finally twice with absolute ethanol. The washing process is all realized by centrifugation at 8000 rpm for 2 min, and...

Embodiment 3

[0054](1) Weigh 3.7142 g of fumaric acid (C 4 h 4 o 4 , 99.0 %) was added to 40 mL of dimethylformamide (HCON(CH 3 ) 2 , AR), after stirring and mixing at 750 rpm for 2 hours, a transparent dispersion was obtained. Then weigh 0.8080 g ferric nitrate (Fe(NO 3 ) 3 9H 2 O, 98.5%) and 0.2974 g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O, 99.0%) was added to the above-mentioned dispersion liquid, stirred at the same speed of 750 rpm for 3 hours, mixed evenly, transferred to a 50 mL sealed steel shell of a hydrothermal kettle, and heated in an electric constant temperature blast drying oven at 150 ℃ The reaction was carried out at the temperature for 12 h. After the temperature is lowered to room temperature, the hydrothermal reaction product is separated from the solid and liquid, and the obtained solid is first washed with absolute ethanol for 3 times, then washed with dimethylformamide for 2 times, and finally washed with absolute ethanol for 3 times. The washing process is all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com