Composite Ti-HA material and its preparing process

A composite material and sintering equipment technology, applied in prosthetics, medical science, etc., can solve problems such as the non-reaction of HA and Ti, macro sintering, high sintering temperature, etc., and achieve the effect of good compactness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

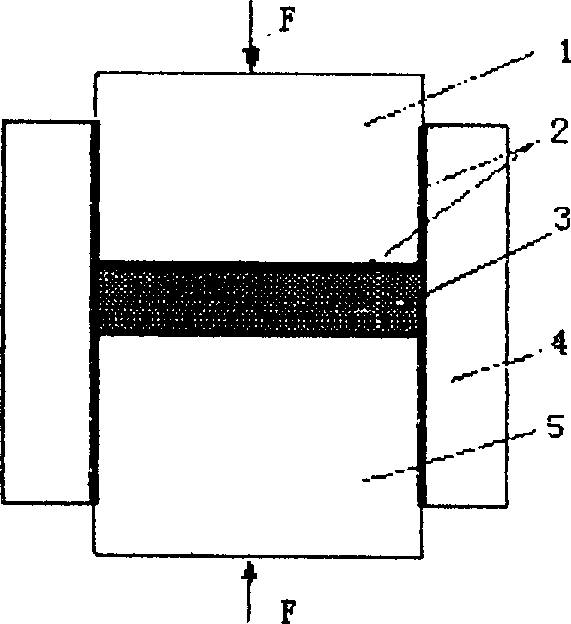

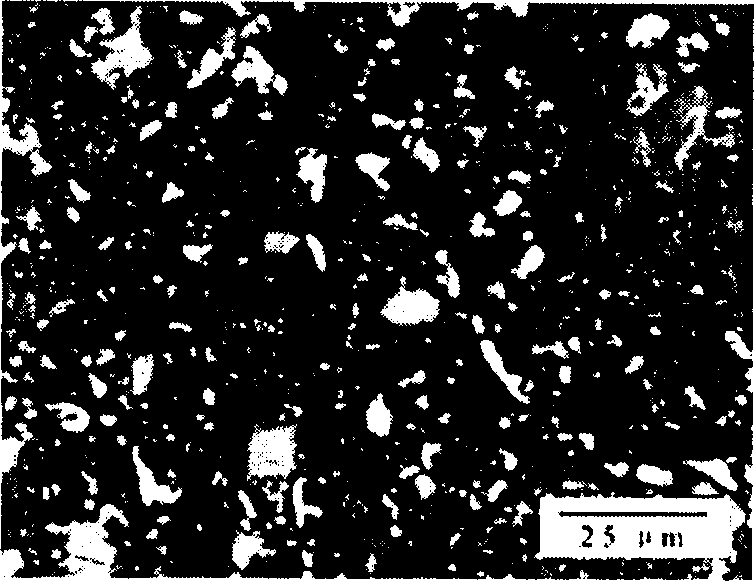

[0015] 1. Take 4.8g of hydroxyapatite powder, 4.8g of titanium powder and 0.4g of water glass for powder mixing, put them into a powder mixer for mixing, after mixing evenly, bake in an oven at 100°C for 1 hour. Then weigh 4g of the above-mentioned mixed powder and put it into a φ24 graphite mold, compact it, put it into a spark plasma sintering equipment, evacuate to 4Pa, apply a pressure of 30MPa, heat up at a rate of 100°C / min, heat up to 870°C for 3min, and slowly Cool to room temperature and take out to obtain Ti / HA composite material, the performance test of which is shown in Table 1.

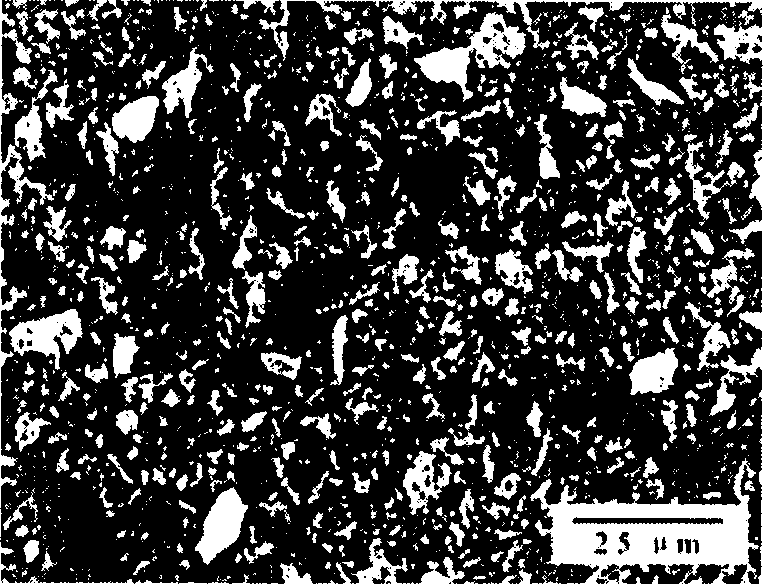

[0016] 2. Take 5.95g of hydroxyapatite powder, 3.55g of titanium powder and 0.5g of water glass for powder mixing, put them into a powder mixer for mixing, after mixing evenly, bake in an oven at 100°C for 1 hour. Then weigh 4g of the above-mentioned mixed powder and put it into a φ24 graphite mold, compact it, put it into a spark plasma sintering equipment, evacuate to 4Pa, apply a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com