Plasma discharge reactor having multiple rotary disk electrodes with more tips

A technology of rotating electrode and plasma, applied in the field of plasma discharge reactor, can solve problems such as difficulty in realizing industrialization, and achieve the effect of less carbon deposition and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

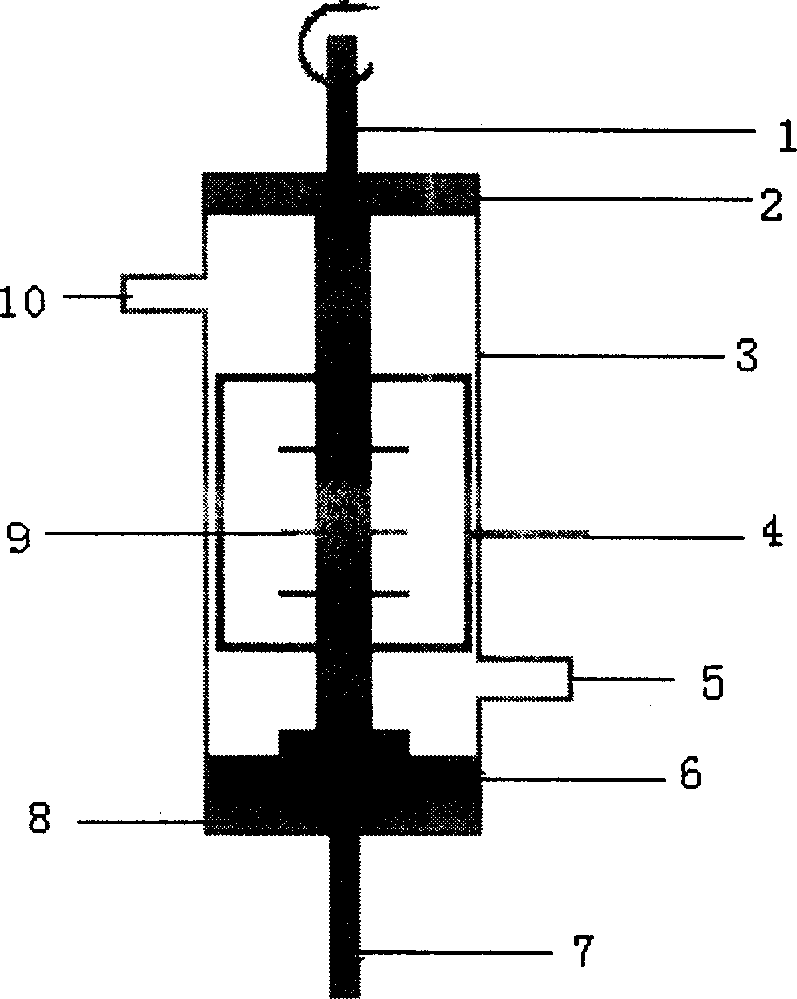

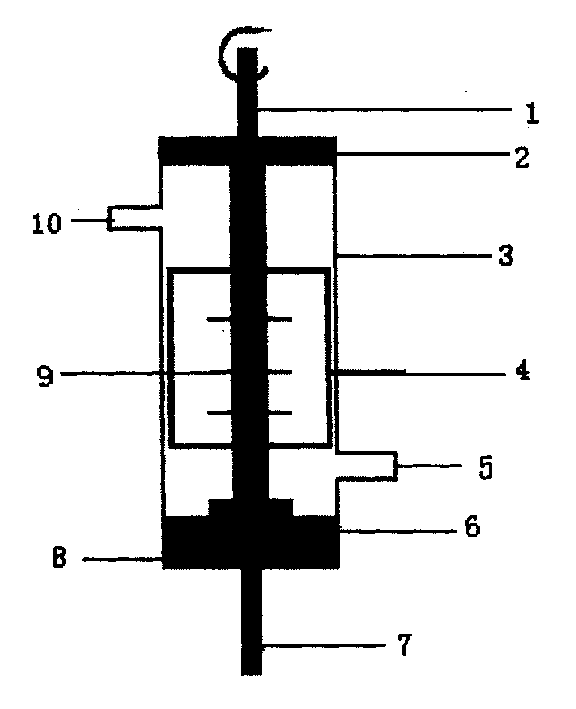

[0011] The present invention is described as follows in conjunction with the accompanying drawings: In the figure, the inner diameter of the insulating shell of the reactor is 11-1010 mm. The distance between multiple concentric discs on the rotating electrode column in the casing is more than 10mm, the diameter of the column is 3-50mm, the diameter of the disc is 5-10mm, and the thickness is 1-5mm. The height is 1-20mm, and the number of teeth is more than 4. The experimental process mainly includes five parts: gas flow control, electrode rotation control, high voltage power supply, digital oscilloscope and gas chromatographic analysis. Reactive gas CH 4 and H 2 The flow of the gas passes through the mass flow controller in two paths and is displayed by the flow display instrument. After mixing, it enters the gas chromatograph and the reactor successively. During the reaction, the reaction gas passes through the discharge zone almost continuously. The high-voltage power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com