Process for treating steel slag

A treatment method and technology for steel slag, applied in the direction of recycling technology, improvement of process efficiency, etc., can solve the problems of low added value and affect the quality of steel, and achieve the effects of low cost, solving environmental pollution, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

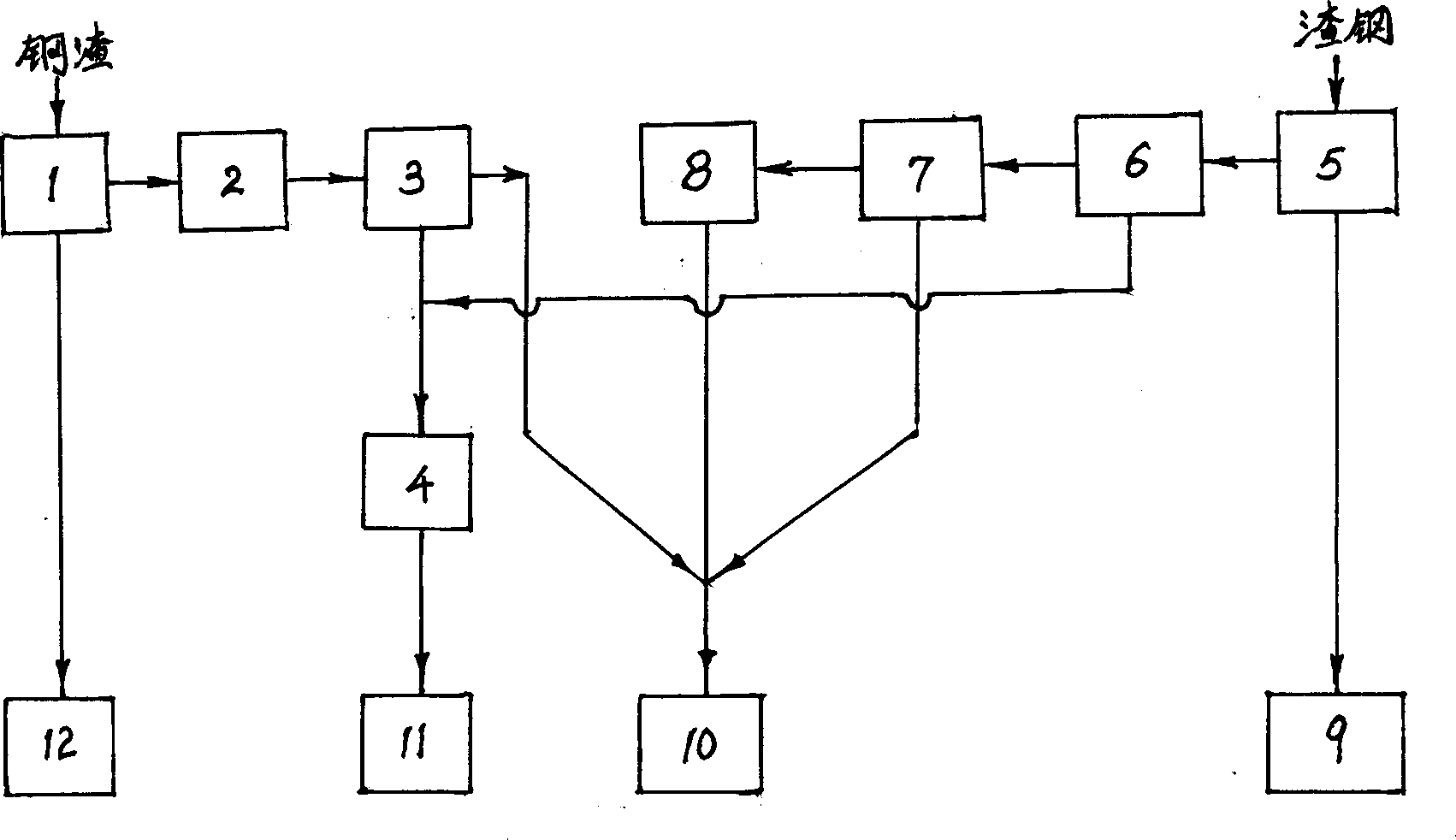

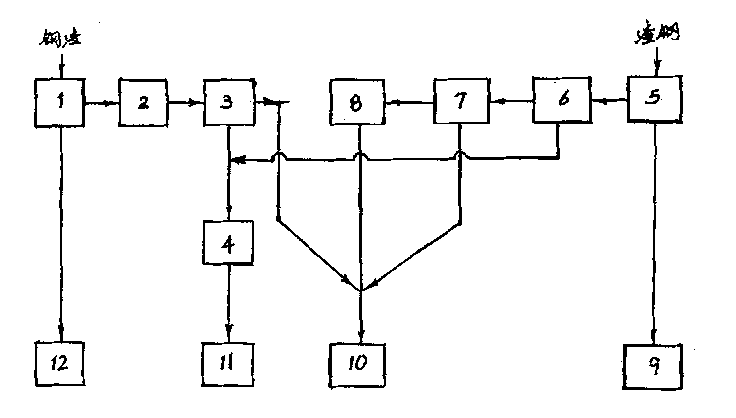

Method used

Image

Examples

Embodiment Construction

[0044] Three batches of steel slag and one batch of steel slag are processed by adopting the steel slag processing method described in the present invention. The raw materials of batch numbers 1, 2, and 3 are steel slag, and the raw materials of batch number 4 are steel slag.

[0045] The particle size and iron content of the four batches of raw materials are shown in Table 1.

[0046] Batch numbers 1, 2, and 3 whose raw material is slag steel enter the air-swept mill 5 for grinding. Negative pressure operation is used during the grinding process. The air pressure and air flow are also listed in Table 1. After grinding, they are not sucked away by the negative pressure. The settled steel slag is a high-quality steel scrap with an iron content greater than 90% that can be used for steelmaking, and its particle size and iron content are also listed in Table 1. After grinding, the slag steel powder with a particle size of 0-1mm is sucked away by negative pressure and enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com