Process for preparing food function factor gamma-amino-butyric acid

A technology of aminobutyric acid, seeds, applied in the field of food biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

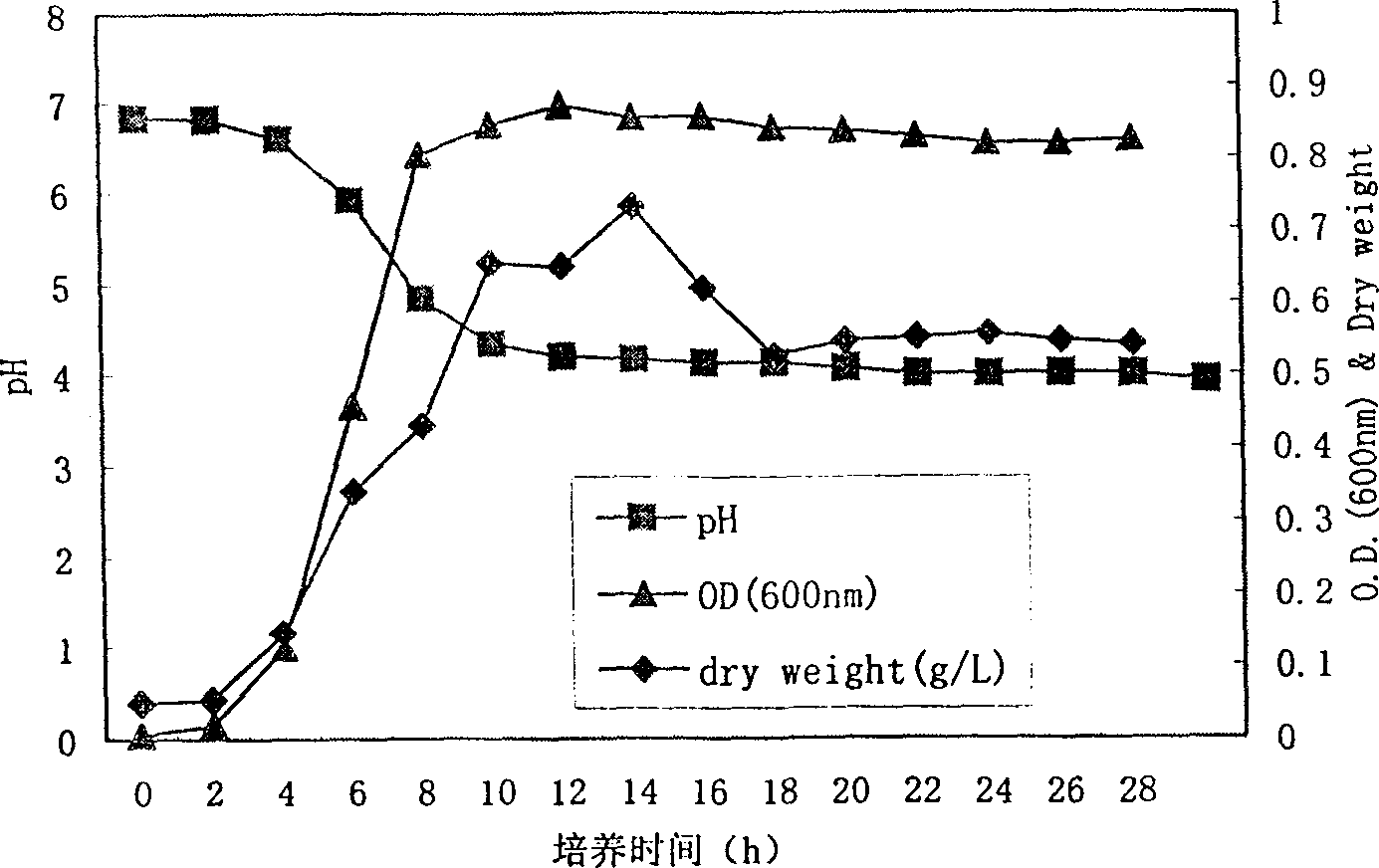

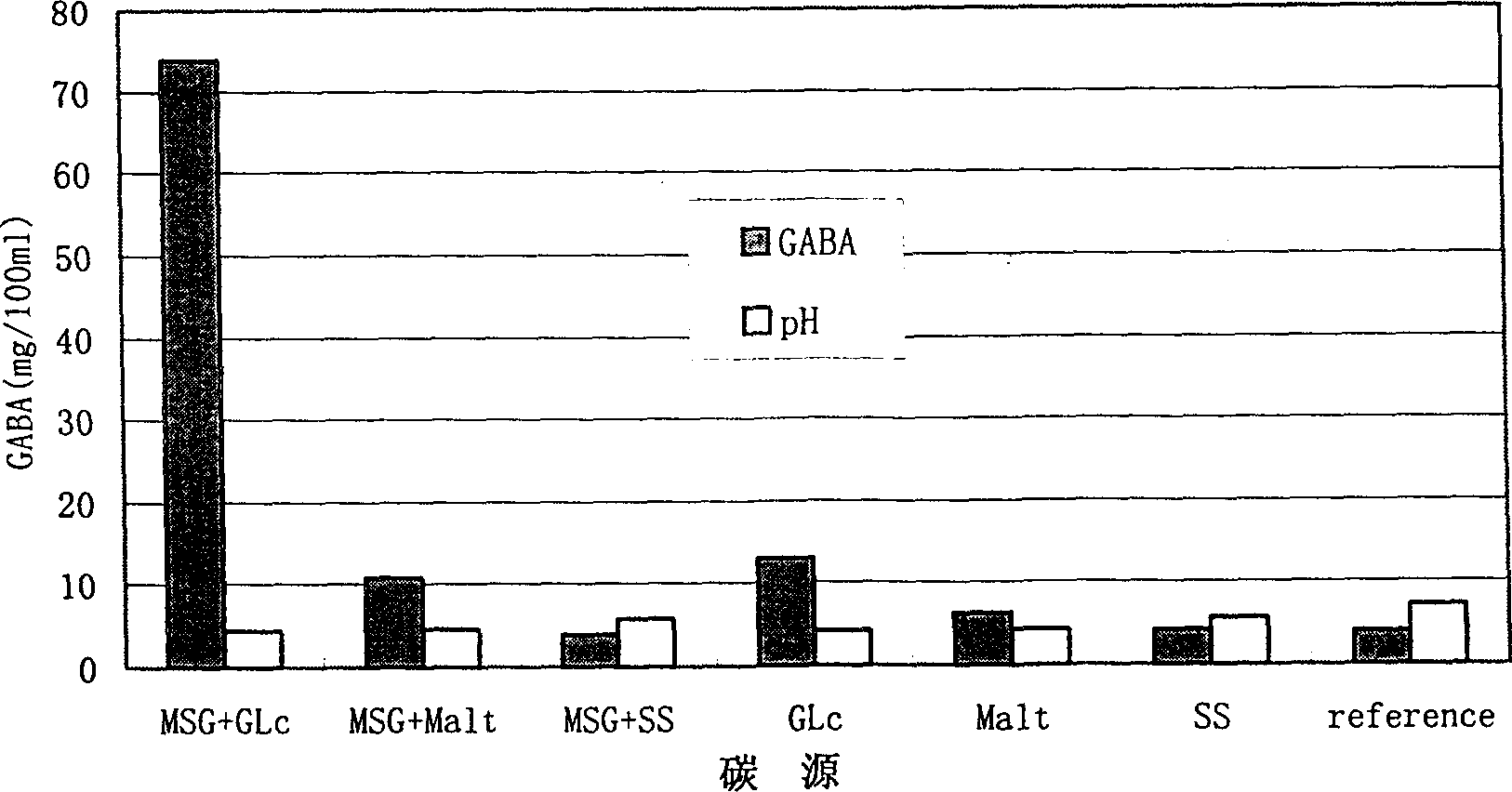

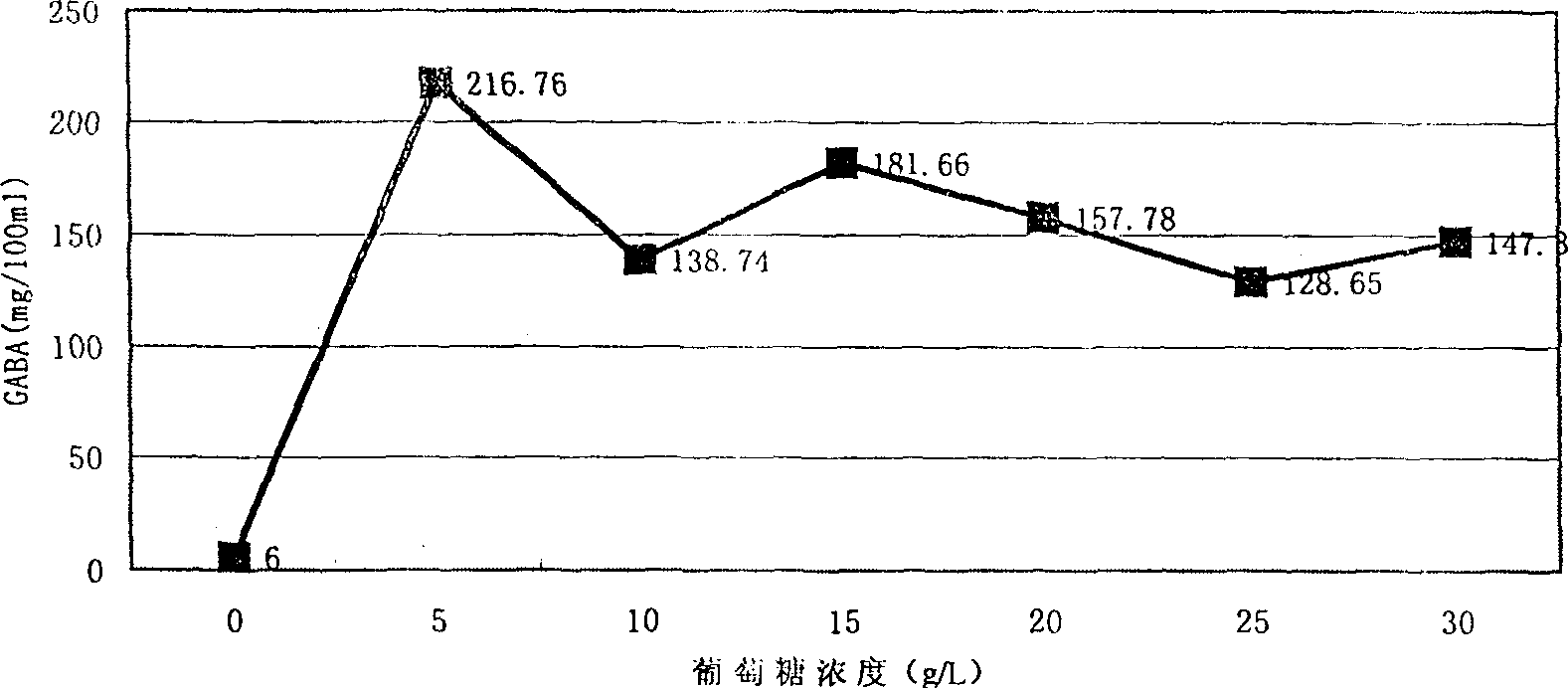

[0050] Select lactic acid bacteria SYFS1.009 as the strain, carry out seed culture in GYP fermentation medium, the inoculum amount is 0.5%, and the culture time is 16 hours. The obtained seed culture solution is centrifuged to collect the bacteria, and the bacteria suspension seeds are made with sterile water liquid, containing 10 8 ~10 9 CFU / ml (plate count). Put 50ml of fermentation medium in a 250ml Erlenmeyer flask, inoculate 0.2% suspended seed solution, add 1% glucose and 1% L-sodium glutamate as carbon source, add 1% casein as nitrogen source, and culture for 24 hours , to get gamma-aminobutyric acid solution, the GABA content is about 280mg / 100ml.

Embodiment 2

[0052] Lactic acid bacteria SYFS1.008 was selected, and the seed culture and fermentation conditions were the same as in Example 1 to obtain a γ-aminobutyric acid solution with a GABA content of about 200 mg / 100 ml.

Embodiment 3

[0054] Select lactic acid bacteria SYFS1.009 and Angel active dry yeast as strains, seed culture and fermentation conditions are the same as in Example 1, first carry out seed culture respectively, then inoculate 0.2% of the suspended seed liquid and mix as seed liquid for fermentation to obtain γ- Aminobutyric acid solution, GABA content is about 300 ~ 350mg / 100ml. The spray-dried powder of the fermented liquid contains 4%-6% of gamma-aminobutyric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com