Catalyst for catalytic hydrogenolysis of unsym-dimethylhydrazine and its prepn

A technology of dimethylhydrazine catalyzing hydrogen and catalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc. High volume, explosive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

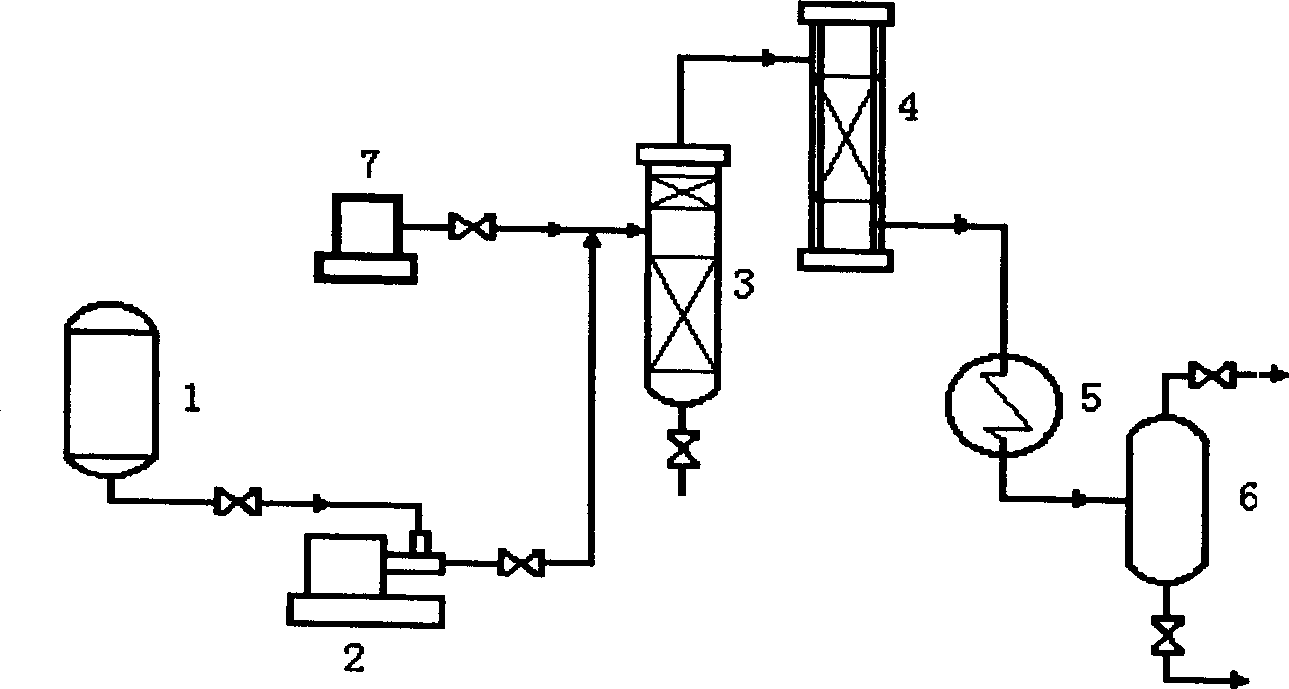

Method used

Image

Examples

example 1

[0016] Weigh 49.72 grams of silicon dioxide as a carrier, prepare an aqueous solution containing 0.51 grams of rhodium chloride and 0.0514 grams of ruthenium trichloride, and use the prepared aqueous solution of silicon dioxide to stand, and then dry at 120°C. Then, it was reduced under hydrogen flow at 300°C to obtain a catalyst. Example 2

example 2

[0017] Weigh 48.75 grams of aluminum oxide support, prepare an aqueous solution containing 2.032 grams of rhodium chloride and 1.24 grams of nickel nitrate hexahydrate, impregnate the support with the prepared solution, place it, then dry it at 120°C and roast at 300°C. Then the catalyst was prepared by reduction at 400°C under hydrogen flow. Example 3

example 3

[0018] Weigh 48.5 grams of silicon dioxide as a carrier, configure an aqueous solution containing 2.032 grams of rhodium trichloride and 1.34 grams of chloroiridic acid, impregnate the silicon dioxide with the configured aqueous solution, let it stand, and then dry it at 120°C and roast at 400°C. Then, the catalyst was prepared by reduction at 300°C under hydrogen flow. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com