Method and apparatus for radiography and radiation detector

A radiography and detector technology, applied in the field of radiography, can solve the problems of high assembly cost, irreplaceable broken modules, high production and assembly costs, etc., and achieve the effects of simplifying manufacturing, reducing manufacturing costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] DESCRIPTION OF THE PREFERRED EMBODIMENT

[0026] figure 1 and figure 2 See Swedish patent application SE-9704015-8 showing an apparatus for plane beam radiography and a gas avalanche chamber according to the prior art. The description corresponding to the above figure provides the reader with a brief introduction to the field of gas avalanche detectors.

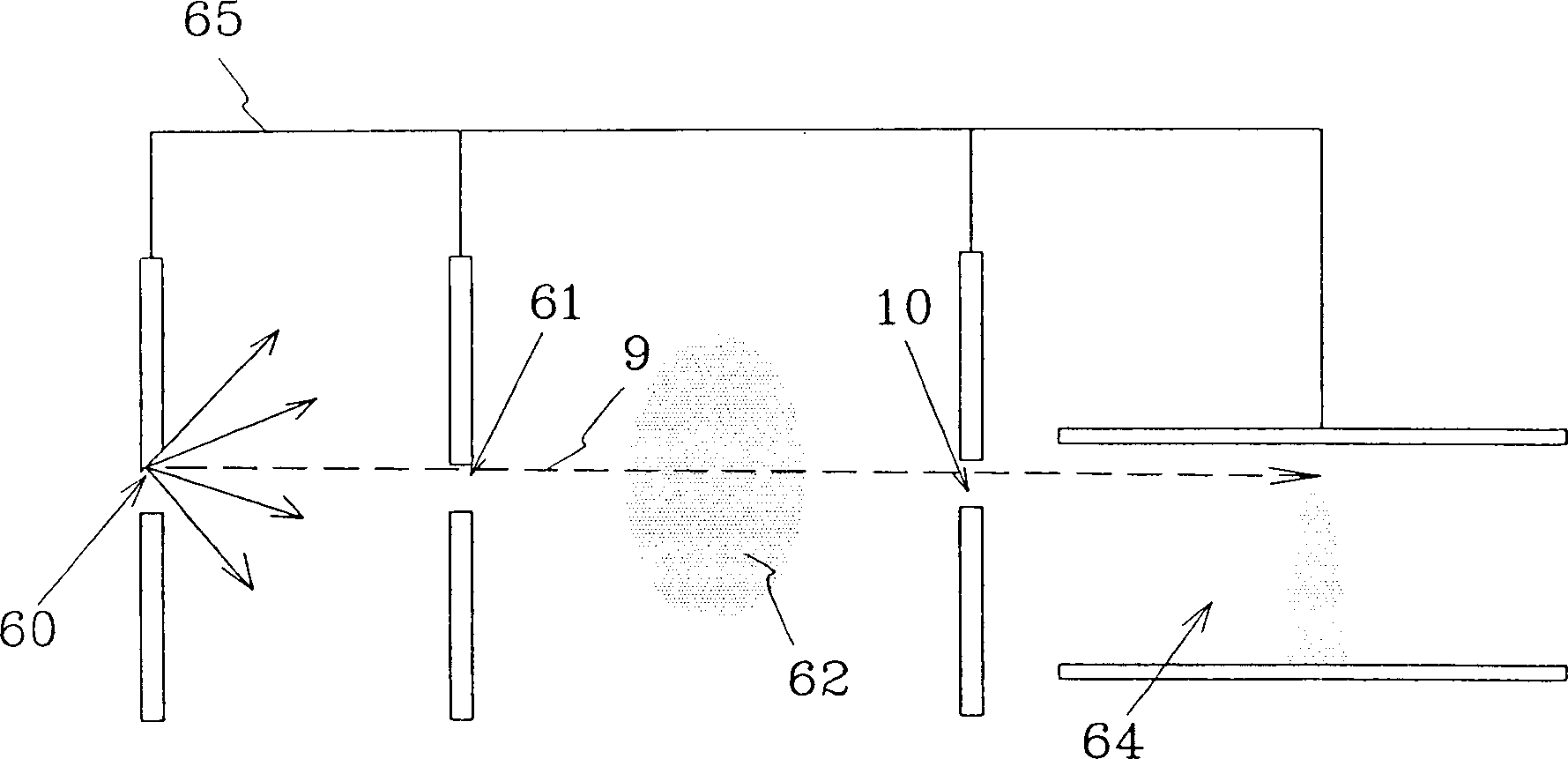

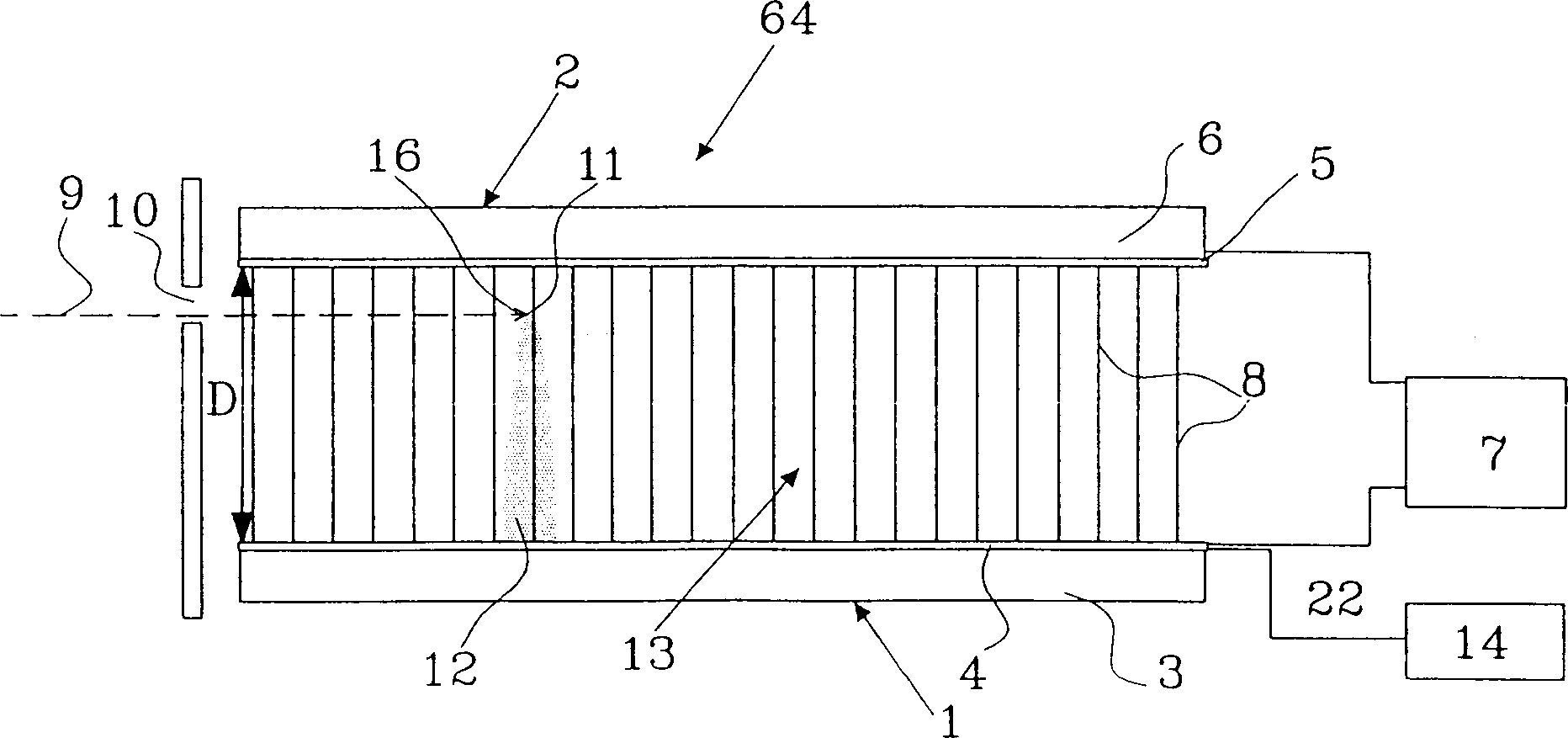

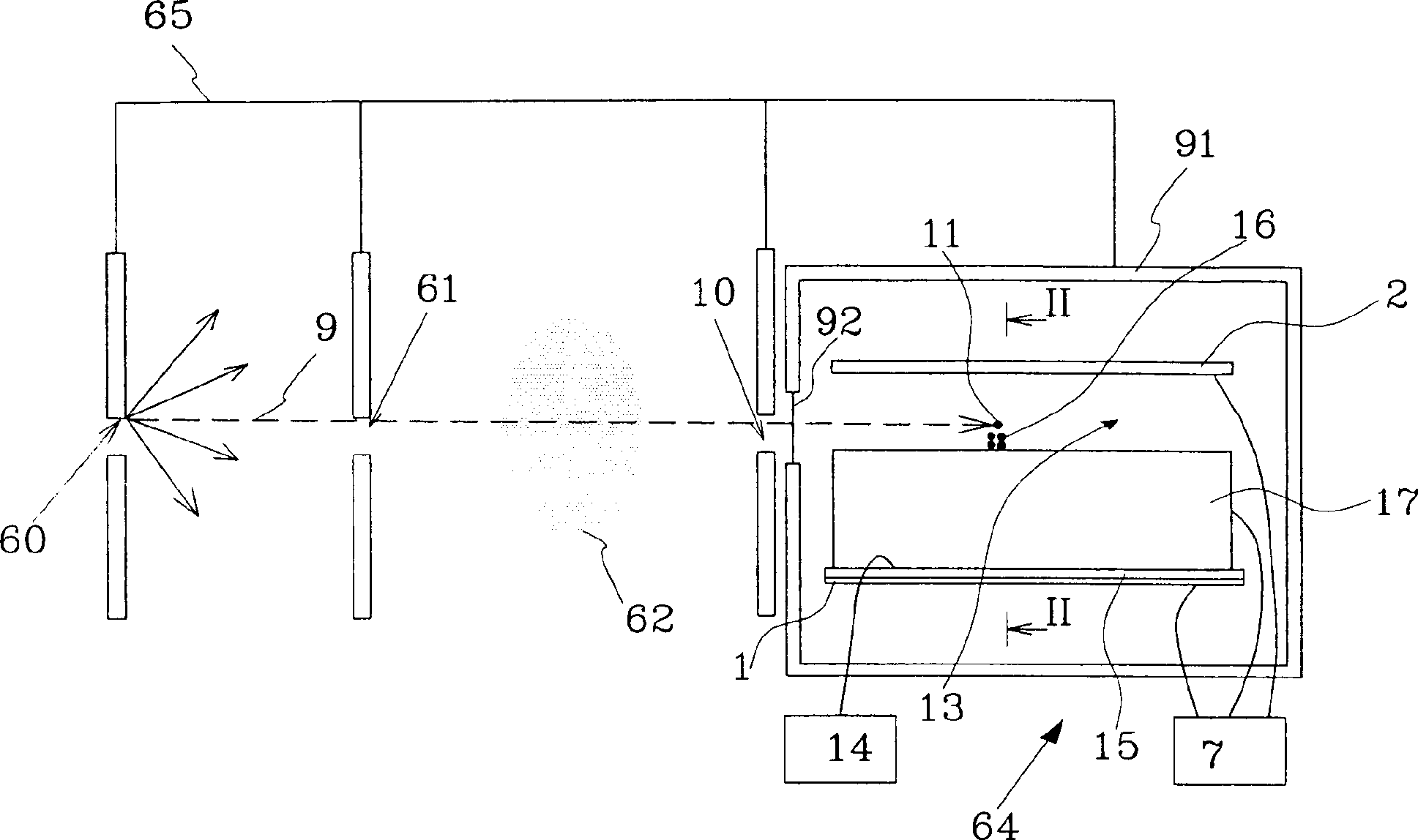

[0027] figure 1 is a sectional view in a plane perpendicular to the plane of the planar X-ray beam 9 of a planar beam radiography apparatus in which a detector comprising a plurality of detector electrode modules according to the invention is arranged.

[0028] The apparatus comprises an X-ray source 60 which, optionally together with a first thin collimator window 61 , generates a planar fan-shaped X-ray beam 9 for radiation to an imaged object 62 . If desired, the first optional thin collimator window 61 may be replaced by another device for forming a substantially planar X-ray beam, such as an X-ray diffraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com