Method for recycling metal gangue in twisting and sucking mode and extraction boat for twisting and sucking metal gangue

A technology for metal tailings and recovery methods, which is applied in special-purpose ships, solid separation, ships, etc., can solve the problems of low excavation efficiency and high energy consumption, and achieve high tailings throughput, simple production process, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

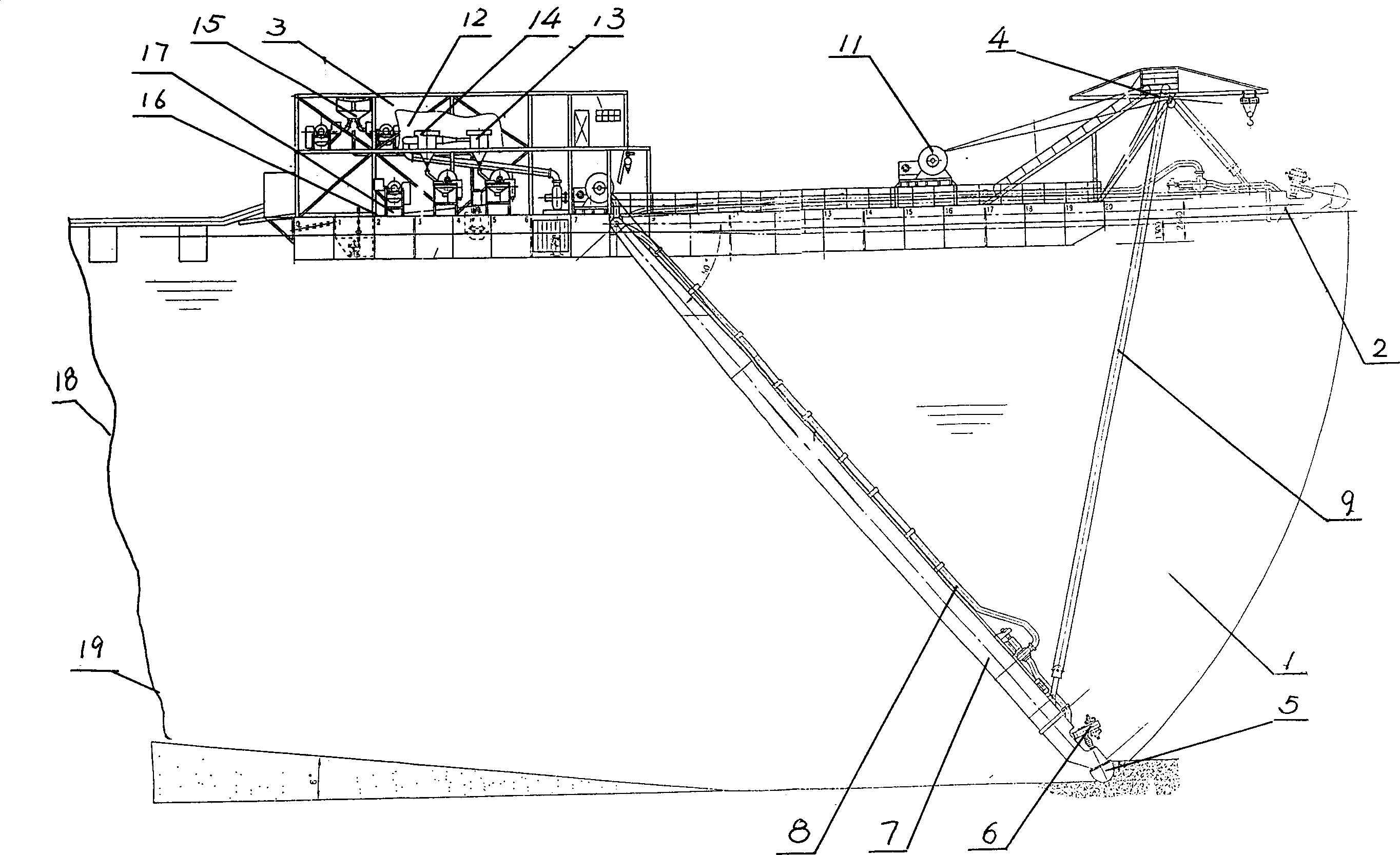

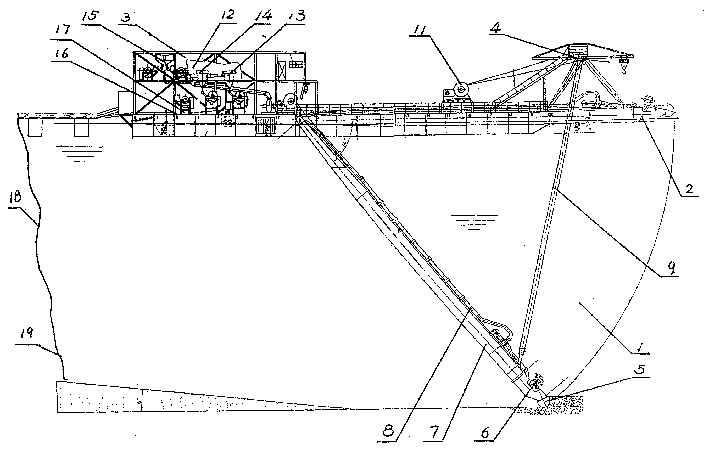

[0010] According to shown in Figure 1, the deck front end of hull 1 is provided with deck mechanical equipment 4, comprises cutter bridge 9, cutter suspension device 10, winch 11, and excavating device 2 is located at hull 1 middle part, and wherein, the cutter suction long arm 7 One end is hinged on the beneficiation tank 12 on the deck, the top is equipped with a cutter suction pump 6, the conveying pipe 8 is connected between the cutter suction pump 6 and the beneficiation tank 12, the reamer bridge 9 is respectively connected with the top of the long arm 7 of the cutter suction and the reamer The suspension device 10 is hingedly connected, and the winch 11 can control the lifting of the winch suction long arm 7. The bottom of the beneficiation tank 12 is a roughing mechanism 13, and the upper part is provided with a beneficiation water supply equipment 15. The tail end is connected by a beneficiation mechanism 14. There are a concentrate conveyor belt 16 and a tailings conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com