Technological process and equipment for catalytically oxidizing HCl to produce CL2

A technology for catalytic oxidation and hydrogen chloride, applied in chlorine/hydrogen chloride, chemical instruments and methods, preparation with chloride, etc., can solve the problem of difficult to realize the circulation of catalyst particles, and achieve simple equipment and instruments, less investment, and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

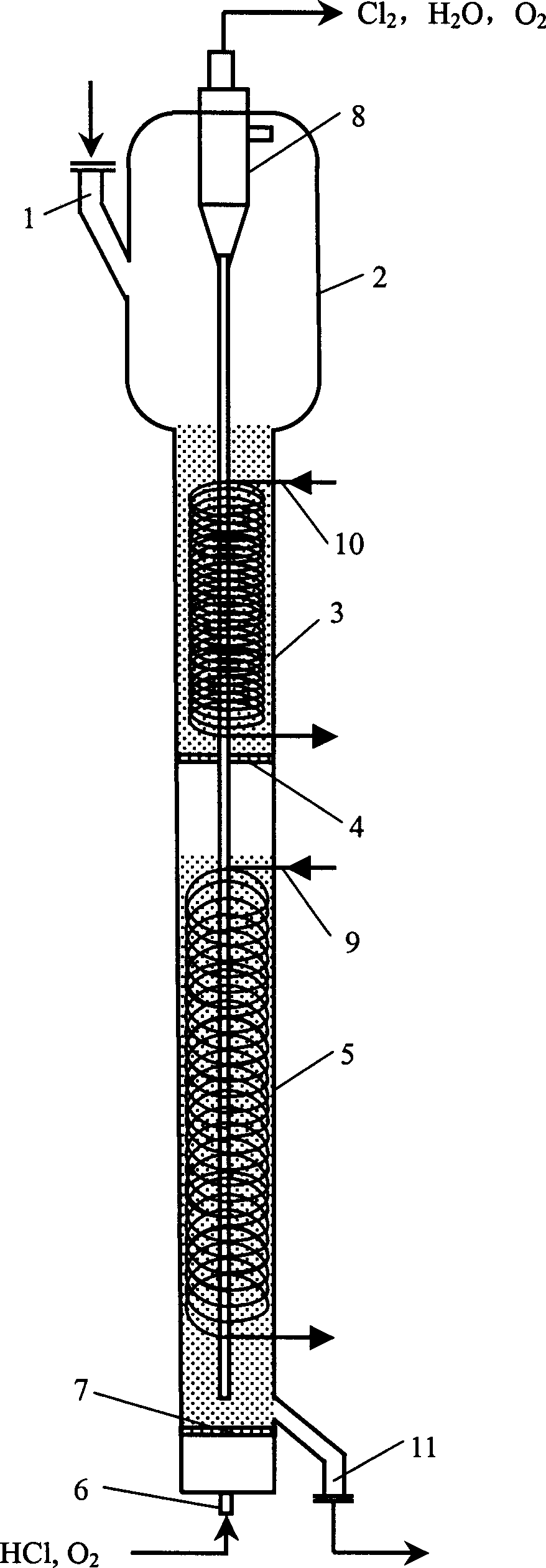

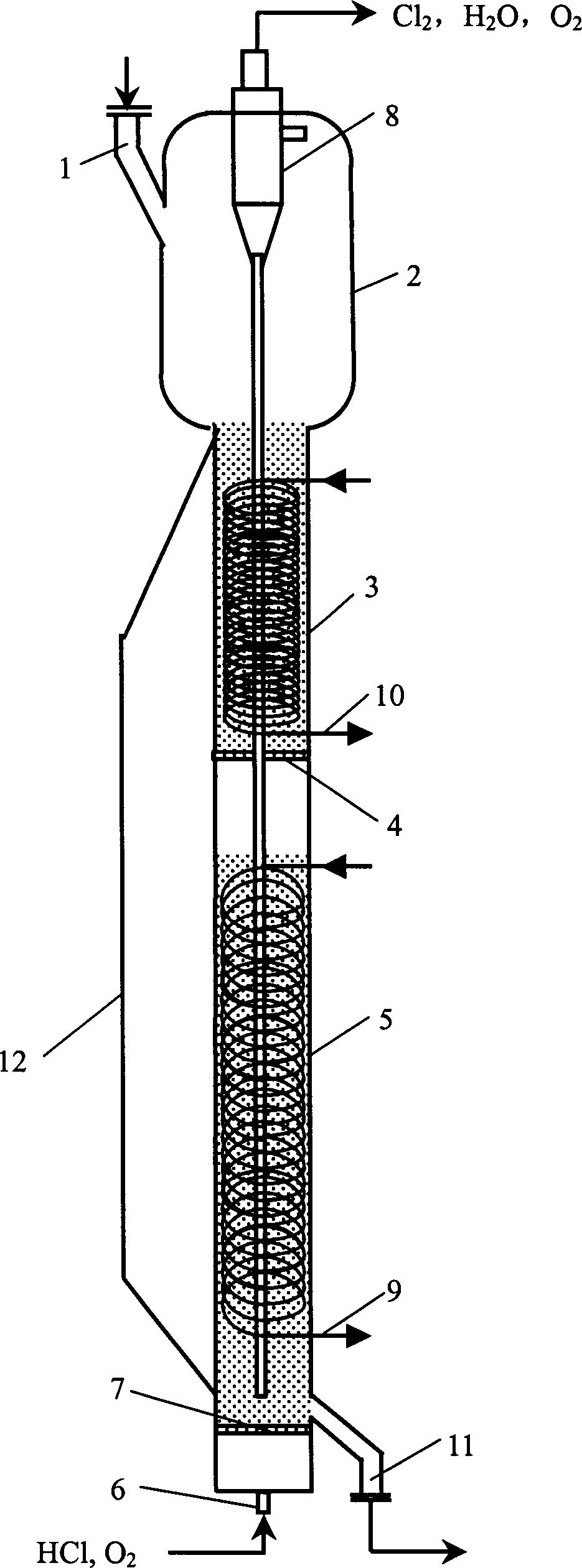

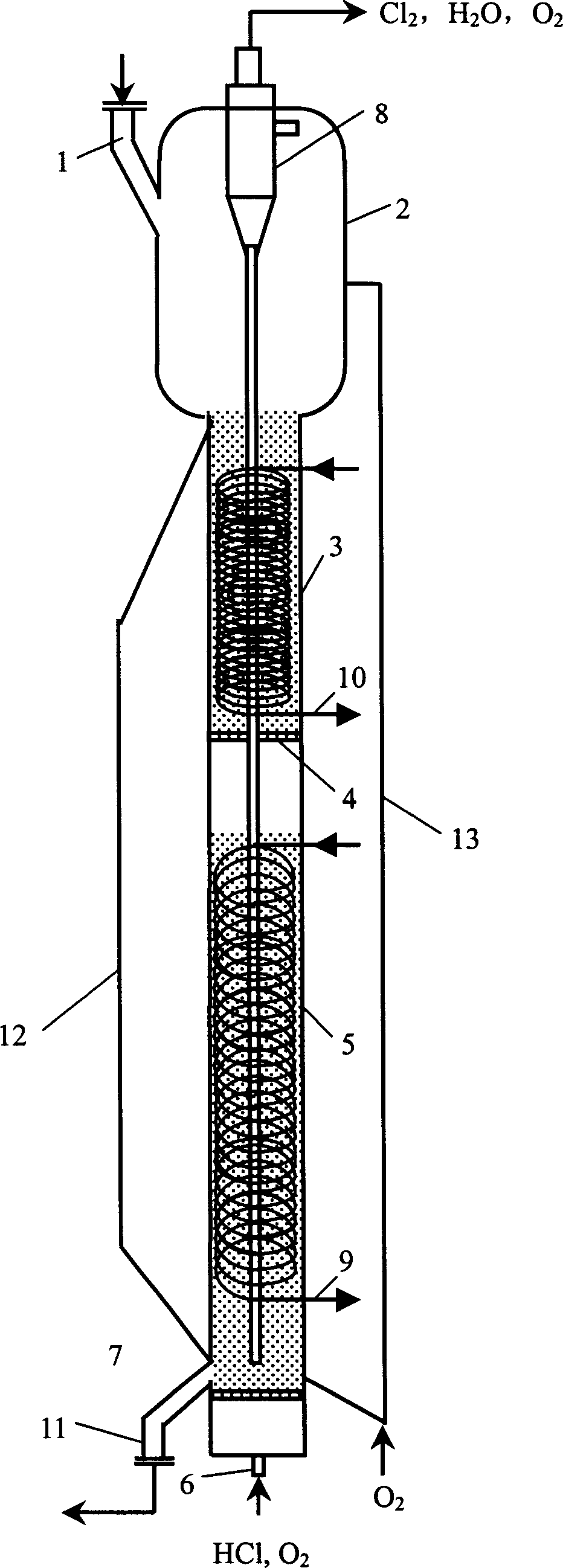

[0043] The catalyst enters the reactor main body from the gas-solid separation chamber 2 through the catalyst inlet 1 . In order to make the catalyst fully enter the reactor, when the catalyst is added, oxygen or air is fed through the gas distributor 7 at the inlet 6 of the gas raw material at the bottom of the reactor. When the gas velocity of oxygen or air is small, most of the catalyst particles stay in the oxidation reactor 5. As the gas velocity increases, the catalyst particles gradually migrate to the chlorination reactor 3 through the gas-solid distribution plate 4, the height of the dense phase in the oxidation reactor 5 gradually decreases, and the height of the dense phase in the chlorination reactor 3 gradually increases. As the gas velocity continues to increase, the amount of particles in the chlorination reactor gradually exceeds the amount of particles in the oxidation reactor; when the particles in the oxidation reactor will be completely blown out, it is an ...

Embodiment 1

[0049] in such as figure 1 The shown two-stage fluidized bed device for producing chlorine from hydrogen chloride reacts. The feed is hydrogen chloride and oxygen with a molar ratio of 2:1; the temperature in the oxidation reactor is 400°C and the pressure is 0.05MPa; the temperature in the chlorination reactor is 200°C and the pressure is 0.01MPa; the weight space velocity is 0.3 Hour -1 , the superficial velocity of the raw gas is 0.45 m / s. The reaction hydrogen chloride conversion rate is 100%, and the selectivity is 99.5%.

Embodiment 2

[0051] in such as figure 1 The shown two-stage fluidized bed device for producing chlorine from hydrogen chloride reacts. The feed is hydrogen chloride and oxygen with a molar ratio of 4:1; the temperature in the oxidation reactor is 380°C and the pressure is 0.05MPa; the temperature in the chlorination reactor is 210°C and the pressure is 0.01MPa; the weight space velocity is 0.2 Hour -1 , the superficial velocity of the raw gas is 0.2 m / s. The reaction hydrogen chloride conversion rate is 95.4%, and the selectivity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com