Unidirectionally see through decorative films

A decorative film and see-through technology, applied in the field of unidirectional see-through decorative films, can solve the problems of impairing the transparency of through-holes, deteriorating the transparency, and being difficult to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

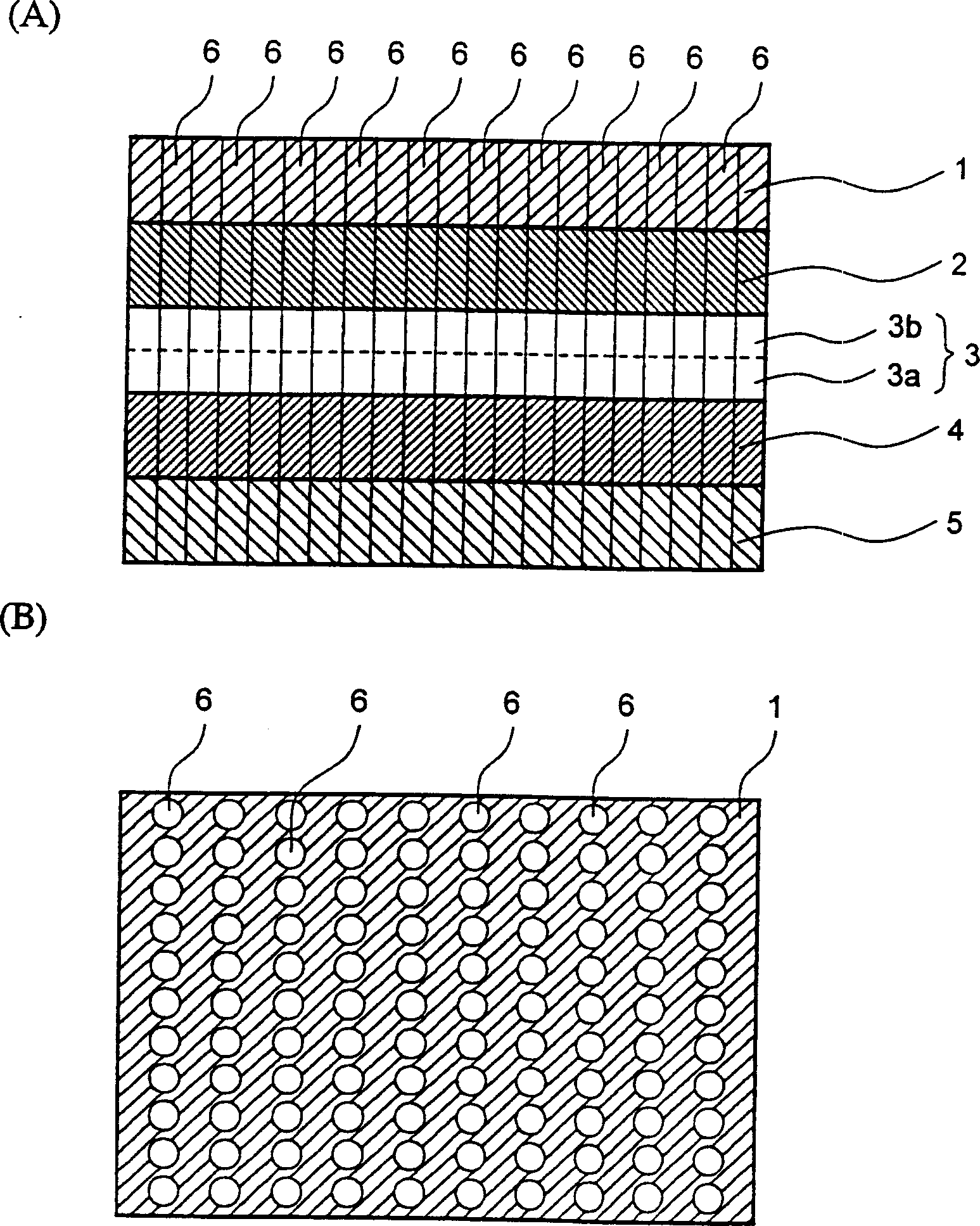

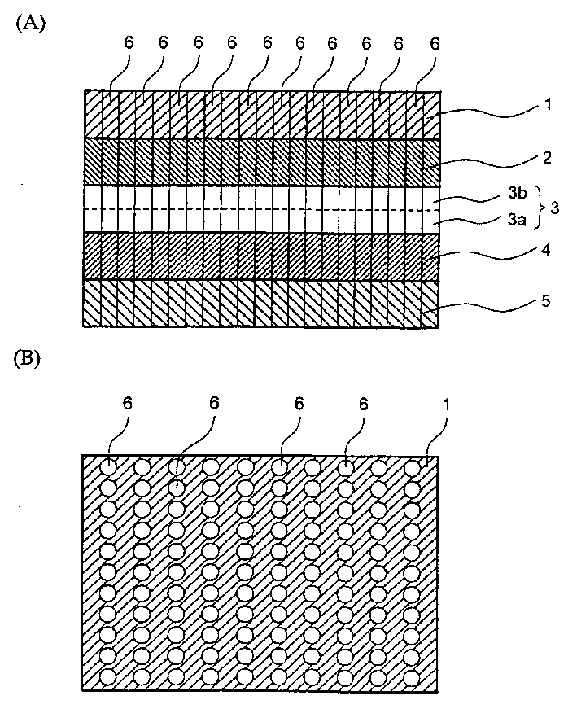

[0042] On a biaxially stretched transparent polyester film (Teijin Tetron Film S6, trade name, manufactured by Teijin Co., Ltd.) with a thickness of 50 micrometers, a tetrafluororesin coating (DUFLON 4F FreshWhite, trade name, manufactured by Nippon Paint Co., Ltd.) was first laminated to 15 Micron thickness and cured to form a white coating layer as the first layer. Then, a tetrafluororesin paint (fluoroethylene-vinyl ether copolymer-based paint) (DUFLON 4F Fresh White, trade name, manufactured by Nippon Paint Co., Ltd.) was laminated to a thickness of 15 μm and cured to form a second layer Blackout color coating. Thereafter, a pressure-sensitive adhesive layer was laminated on the reverse side of the film and a heat-resistant release layer was laminated thereon. Circular through-holes with a diameter of 1.5 mm were regularly perforated on the entire surface of the film with a porosity of 50%. Thus, a unidirectional see-through decorative film is prepared. A sublimation dy...

Embodiment 2

[0044] On a 50 micron thick biaxially stretched transparent polyester film (Teijin Tetron Film S6, trade name, Teijin Co., Ltd.), first laminate a single-liquid thermosetting polyester resin clear coating (SENOKOYL, trade name, manufactured by Cashew Corporation). system) to a thickness of 30 microns and cured to form a clear coating layer as the first layer. Then follow the same procedure as in Example 1 using the same "DUFLON 4F Fresh White" layer combination as the 2nd layer of white coating. Then, follow the same procedure as in Example 1, using the "DUFLON 4F FreshBlack" layer as the 3rd layer of opaque color coating. Thereafter, an adhesive layer was laminated on the opposite surface of the film, and a heat-resistant barrier layer was bonded thereon. Through-holes exactly the same as those in Example 1 were drilled on the entire surface of the film to prepare a decorative film. On the black paint-coated side of this decorative film, thermal transfer was performed in th...

Embodiment 3

[0046] On the biaxially stretched transparent polyester film (Teijin Tetron Film S6, trade name, manufactured by Teijin Co., Ltd.) with a thickness of 50 μm, first laminate two-liquid thermosetting polyacrylic polyurethane clear coatings (Acrylic Urethane Resin Vanish 7987, trade name name, manufactured by Isamu Paint) to a thickness of 30 micrometers and cured to form a clear coating layer as the first layer. Then follow the same procedure as in Example 1 using the same "DUFLON 4F Fresh White" layer combination as the 2nd layer of white coating. Then, follow the same procedure as in Example 1, using the "DUFLON 4F Fresh Black" layer as the 3rd layer of opaque color coating. Thereafter, an adhesive layer was laminated on the opposite surface of the film, and a heat-resistant barrier layer was bonded thereon. Through-holes exactly the same as those in Example 1 were drilled on the entire surface of the film to produce a decorative film. On the black paint-coated side of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com