Fluorinated and siliceous copolymer resin and paint

A copolymer and resin technology, applied in the direction of coating, can solve the problems of high pressure, inconvenient use, difficult operation, etc., and achieve the effect of good adhesion, good chemical resistance, and improved aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

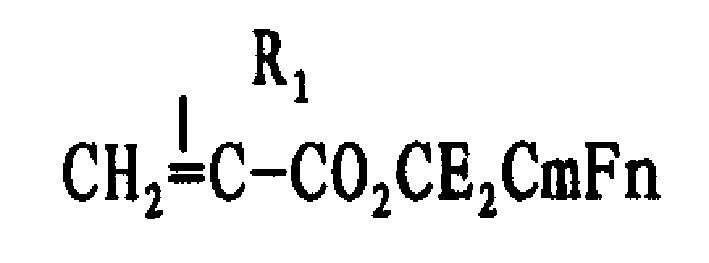

Image

Examples

Embodiment Construction

[0033] The following examples illustrate the present invention, but do not limit Examples 1-5 of the present invention. (1) Equipment and polymerization process used in Examples 1-5

[0034] In a reactor equipped with a stirrer, a reflux condenser, a dropping funnel, a thermometer and a heating jacket on the outer wall, add the mixed solvent shown in Table 1 and stir and raise the temperature to 80-90℃, according to the components listed in Table 1. The added amount is dripped into the reaction kettle for 2-3h. After the addition, the stirring is continued and the temperature is kept for 4-8h. After the reaction is completed, the temperature is cooled and the material is discharged. (2) Example 1-5 Addition amount of each component Addition amount of each component Table 1

[0035]

[0036] Performance

[0037] Note: ○ means no change, △ means slight change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com