Ultrasonic wave milk components analysis instrument

An ultrasonic and analyzer technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problems of high cost and complex system requirements, and achieve the effect of overcoming the influence of ultrasonic attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

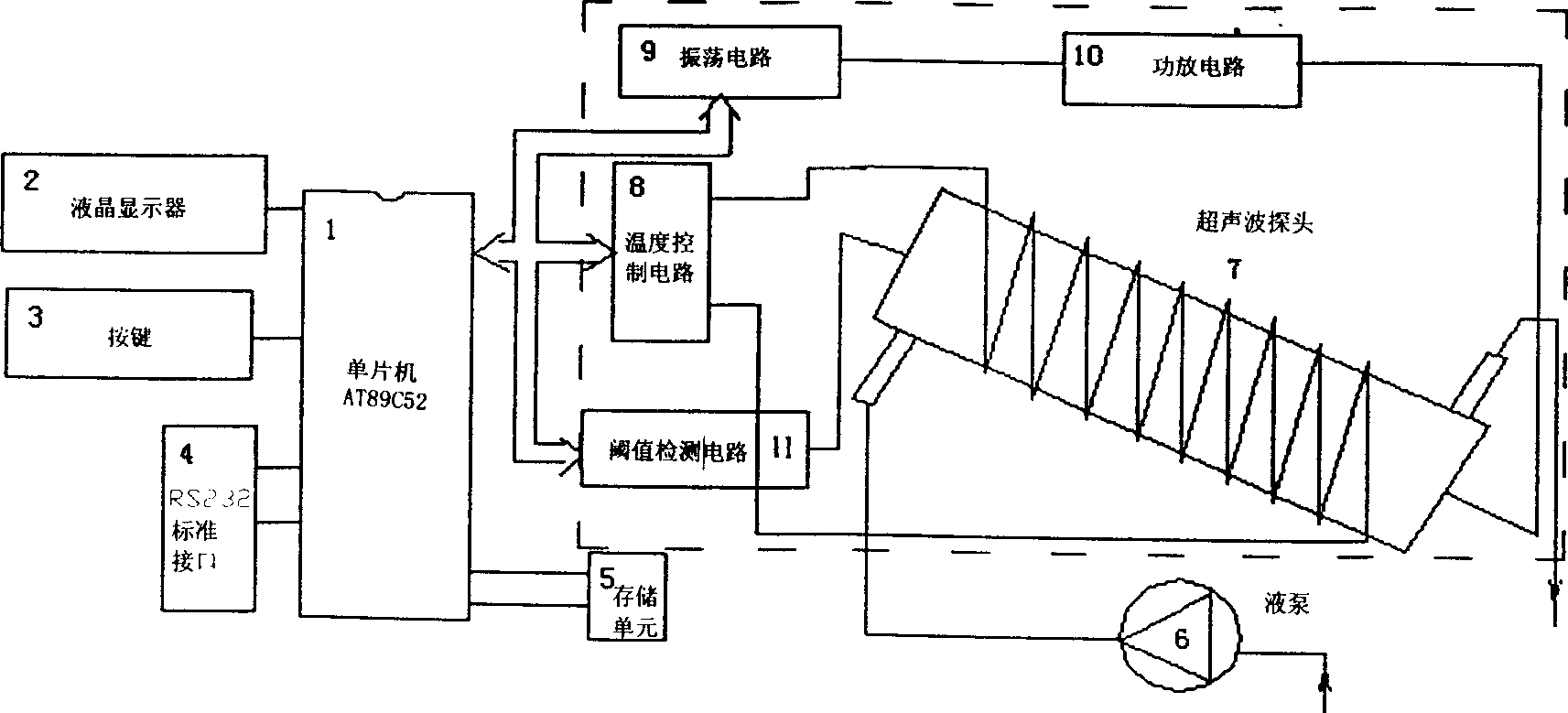

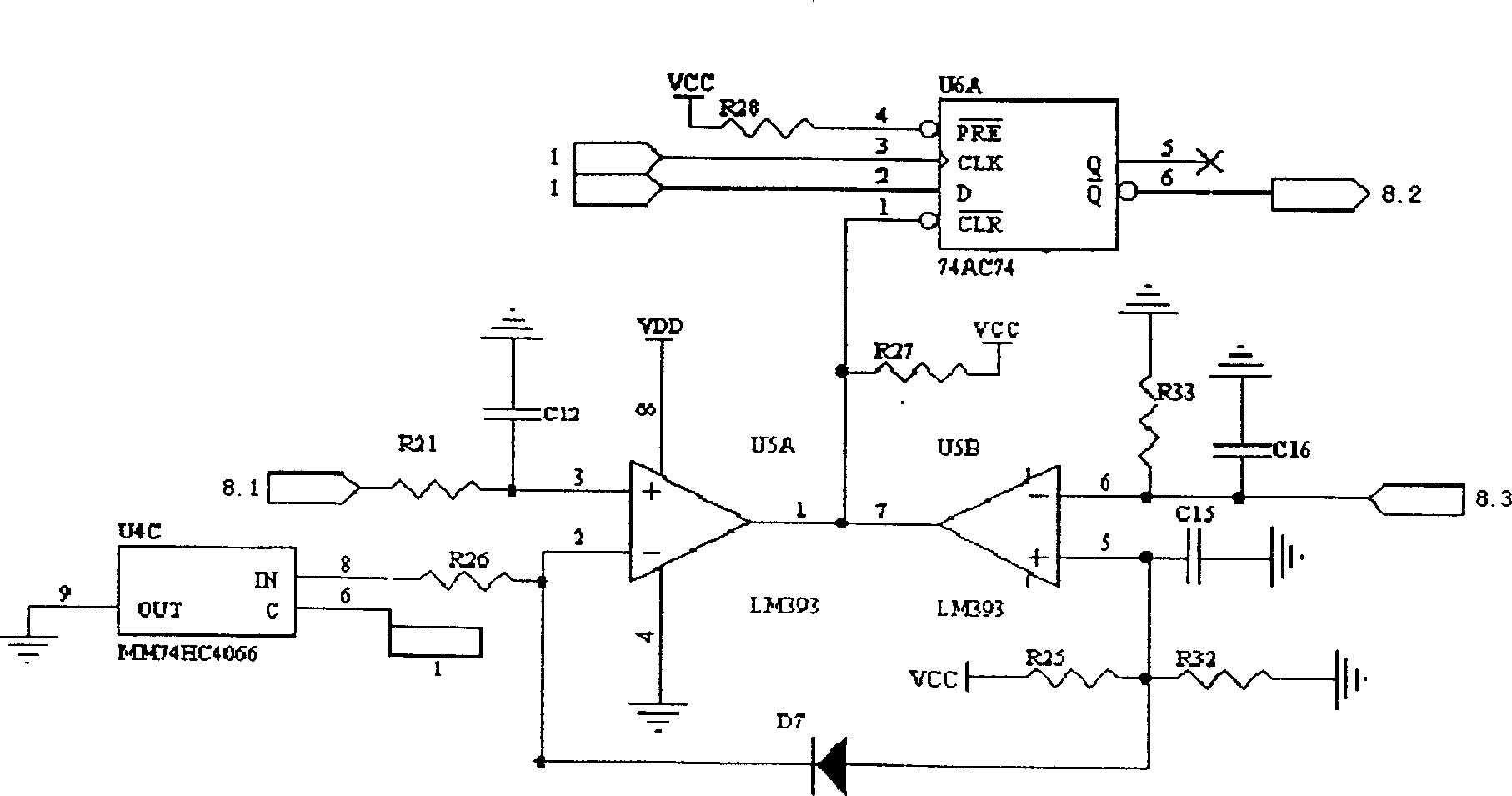

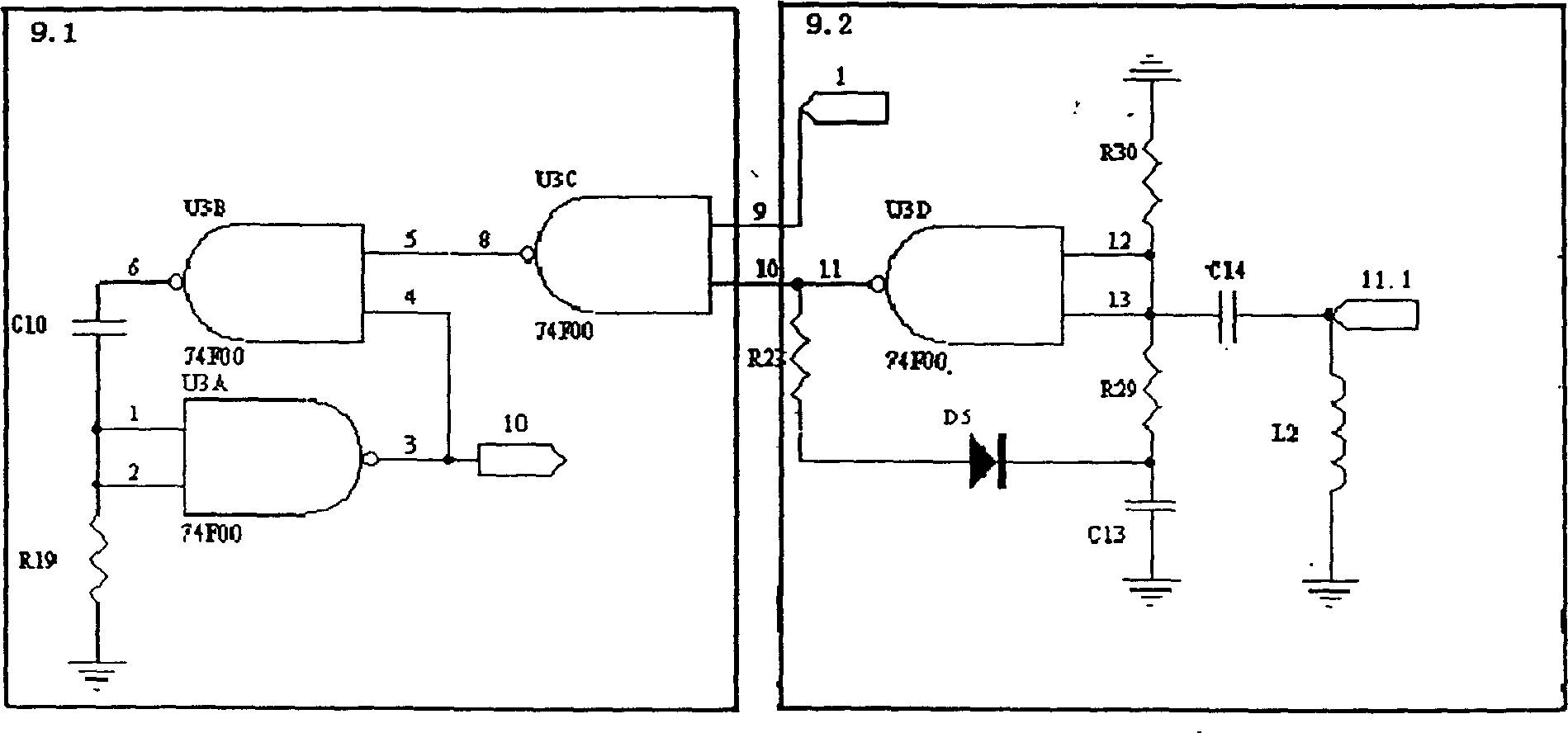

[0029] Such as figure 1 , Figure 6 , Figure 7, Figure 8 As shown, the present invention comprises: AT89C52 single-chip microcomputer 1, the man-machine interface that is made up of liquid crystal display 2, button 3, RS232 standard interface 3, EEPROM storage unit 5, liquid pump 6, by ultrasonic probe 7, temperature control circuit 8, oscillation circuit 9. A detection system composed of a power amplifier circuit 10 and a threshold value detection circuit 11.

[0030] 1) The liquid crystal display 2 and the button 3 are connected to the single-chip microcomputer 1 through the input / output interface and the standard interface 4 through the serial interface;

[0031] 2) storage unit 5 is the storage of programs and fixed parameters;

[0032] 3) The central processing unit CPU controls the oscillating circuit 9 to generate equal-amplitude pulse waves, which are amplified by the power amplifier circuit 10 and then connected to the transmitting end of the ultrasonic probe 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com