Improvements in blood filters, blood collection and processing system and methods therefor

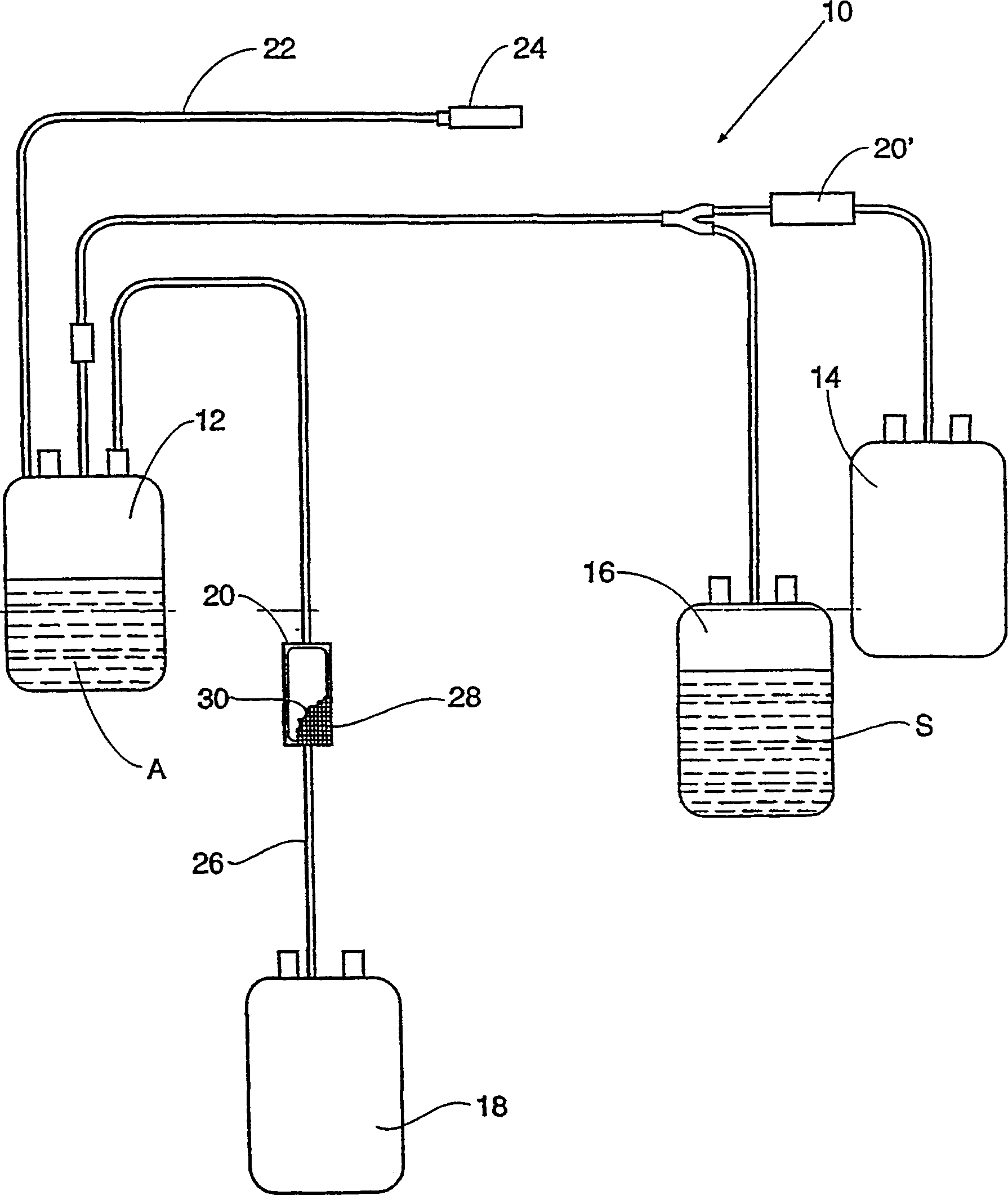

A blood processing and filter technology, applied in the field of blood collection and processing filters, can solve the problems of complex manufacturing process, increased loss of raw materials, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

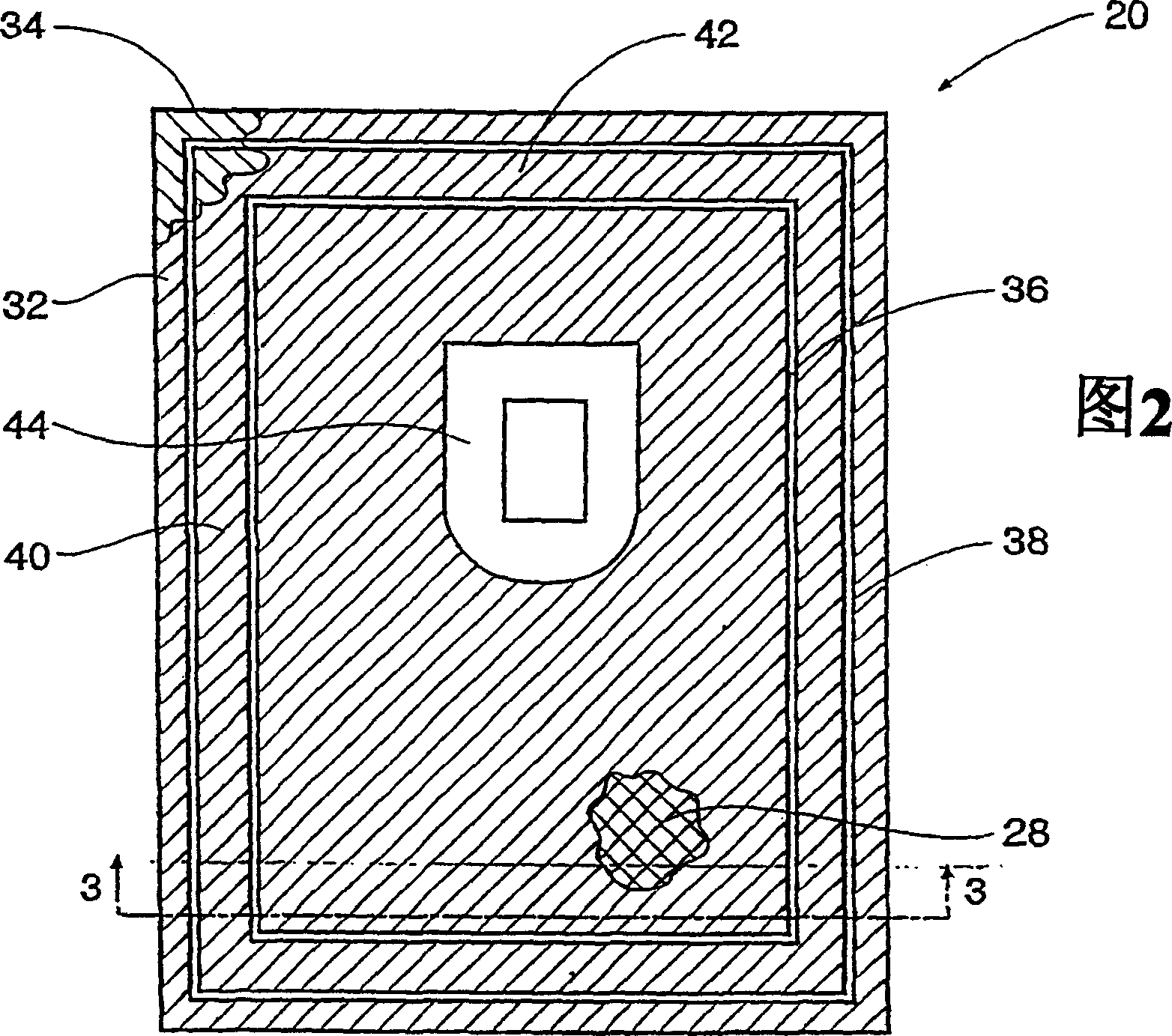

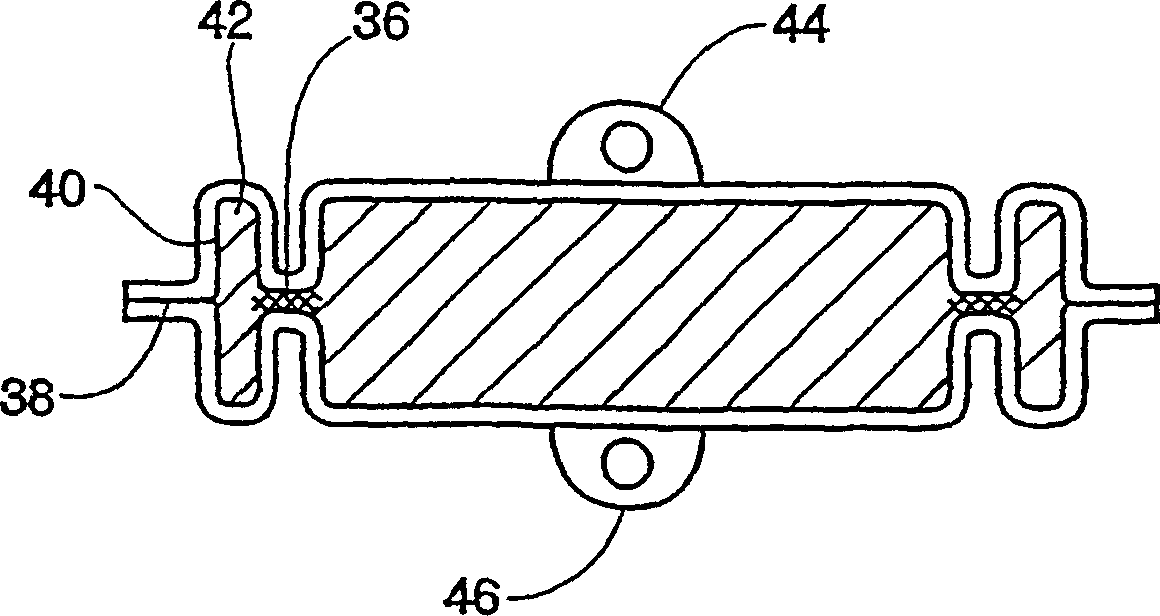

[0110] The elastic polyvinyl chloride resin membranes b and d are cut to the size of the blood filter plus 20mm, and holes are provided on it at positions corresponding to the blood inlet a and the blood outlet e, which are made of polyvinyl chloride resin and formed by injection molding, and the resin films b and d are connected to each other by high frequency welding, thereby manufacturing an elastic case b provided with a blood inlet a and an elastic case d provided with a blood outlet e.

[0111] Polyester nonwoven fibers as described below were laminated to form a filter member c. Laminate the following materials in the following order: four layers of non-woven fiber 1 as the first filter element, its average fiber size is 12-15 μm, and the fiber density is 29-31g / m 2 ;A total of 27 layers of non-woven fibers are used as the second filter element, which includes-having an average fiber size of 1.5-2.0 μm and a fiber density of 65-67g / m 2 A layer of nonwoven fibers 2 havi...

Embodiment 2

[0117] Cut the filter part c into a size of 82mm x 65mm. The first closed area was welded so that the width of the protruding filter member g was 0.5 mm.

[0118] After performing the leak detection of the first closed portion, a filter was produced in the same manner as in Example 1, except that the elastic shells b and d were welded to form a non-closed region h with a width of 1 mm. The results of the leak test performed by the above method are shown in Table 1.

Embodiment 3

[0120] Example 1 was carried out except that the filter member was cut to a size of 87×70 mm so that the width of the protruding part (g) was 3 mm and the width of the non-enclosed area (h) was 6 mm. The difference between the maximum width and the minimum width of the protruding filter member was 1 mm. The results of the leak test before and after sterilization / centrifugation are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap