Halogen-free nonflammable epoxy resin composition, halogen-free nonfammable epoxy resin composition for build-up type multi-layer board

A technology of epoxy resin and polyepoxy compound, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc., and can solve problems such as adverse effects of epoxy resin curing, moisture resistance, heat resistance decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

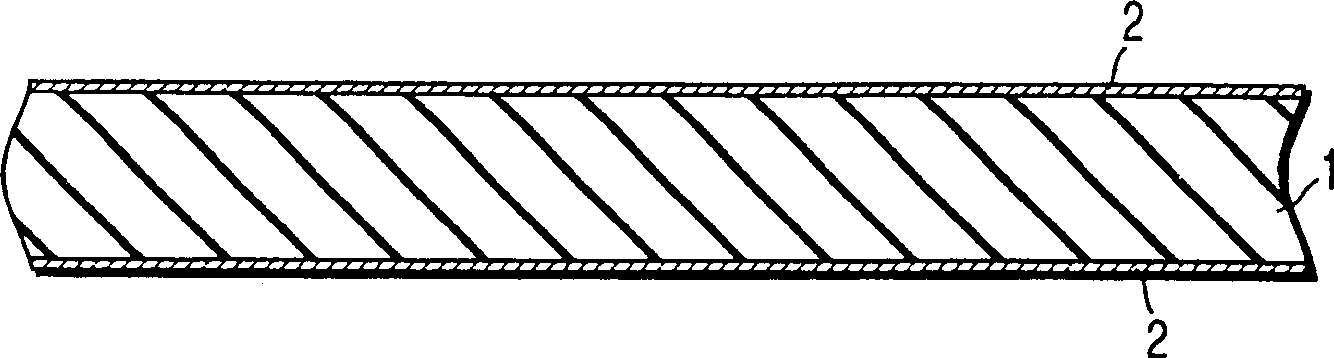

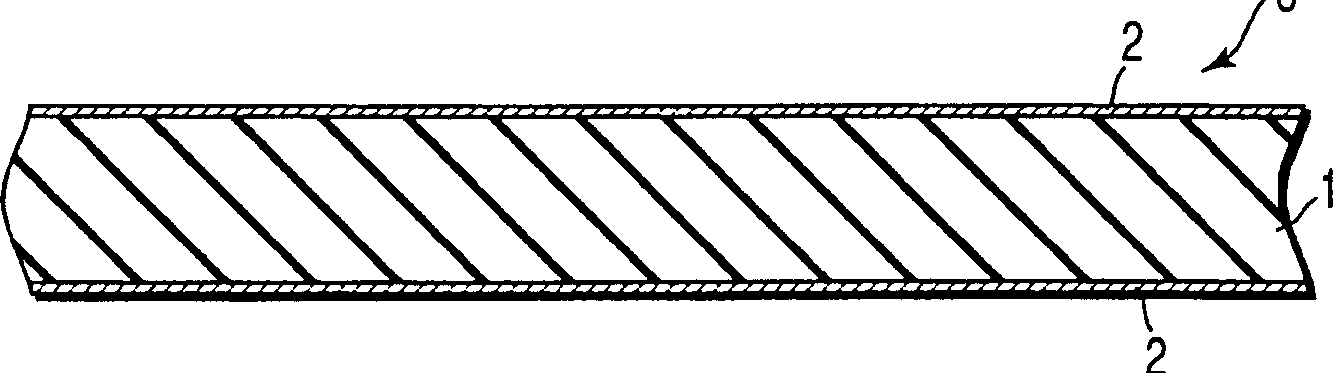

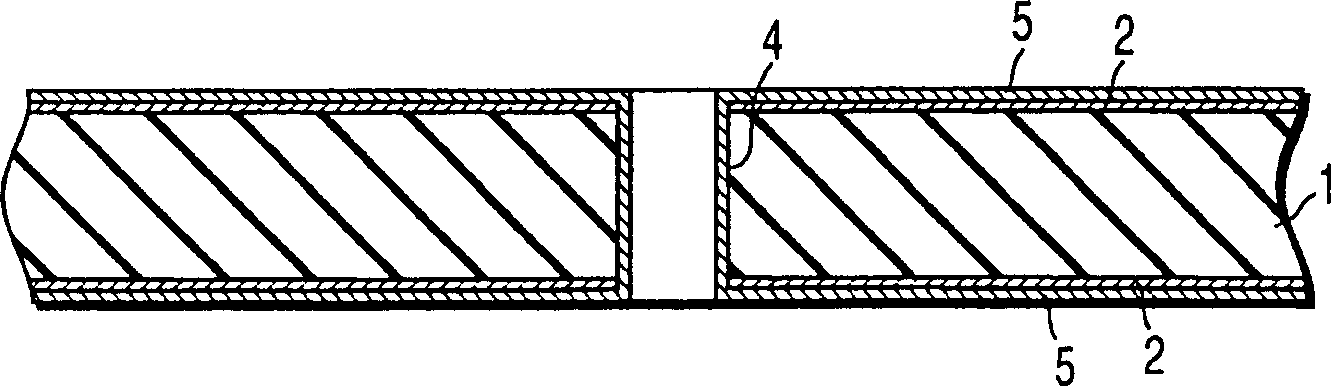

Image

Examples

Synthetic example 1

[0116] (Synthesis of phenoxyphosphazene compound having p-phenylene crosslinked structure)

[0117] A mixture of 103.5 grams (1.1 moles) of phenol, 44.0 grams (1.1 moles) of sodium hydroxide, 50 grams of water and 500 milliliters of toluene was heated to reflux, and only the water was discharged from the system to prepare a toluene solution of sodium phenate.

[0118] Carrying out simultaneously with above-mentioned reaction is: drop into 16.5 grams (0.15 moles) hydroquinone, 94.1 grams (1.0 moles) phenol, 31.1 grams (1.3 moles) lithium hydroxide, 52 grams water and 600 milliliters of toluene in 2 liters of four-necked flasks The mixture is heated to reflux, and only water is discharged from the system, thereby making a toluene solution of lithium salt of hydroquinone and phenol. In this toluene solution, 580 grams containing 1.0 unit moles (115.9 grams) of dichlorophosphazene oligomers (62% for trimers, 12% for tetramers, 12% for pentamers) were added dropwise at below 30°C w...

Synthetic example 2

[0122] (Synthesis of phenoxyphosphazene compound having a 2,2-bis(p-oxyphenyl)isopropylidene crosslinked structure)

[0123] Put 65.9 grams (0.7 moles) of phenol and 50 milliliters of toluene into a 1-liter four-neck flask, and while stirring, keep the internal liquid temperature at 25° C., then drop 0.65 grams of atomic sodium (14.9 grams) into fine pieces. After the input is completed, the stirring is continued at 77-130°C for 8 hours until the metallic sodium completely disappears.

[0124] What is carried out simultaneously with the above reaction is: 0.25 moles (57.1 grams) of bisphenol A, 1.1 moles (103.5 grams) of phenol and 800 milliliters of tetrahydrofuran (THF) are put into a 3-liter four-necked flask, and the internal liquid temperature is kept at 25 At the same time, 1.6 gram atoms (11.1 grams) of lithium metal were finely chopped and put in. After the input is completed, the stirring is continued at 61-68°C for 8 hours until the metal lithium completely disappea...

Synthetic example 3

[0128] (Synthesis of phenoxyphosphazene compound having a 4,4-sulfonyldiphenylene (bisphenol-S residue) cross-linked structure)

[0129] Put 37.6 grams (0.4 moles) of phenol and 500 milliliters of THF into a 1-liter four-neck flask, and while stirring, keep the internal liquid temperature at 25° C., chop 0.45 grams of atomic (9.2 grams) sodium metal into fine pieces. After the input is completed, the stirring is continued at 65-72°C for 5 hours until the metallic sodium completely disappears.

[0130] Simultaneously with the above reaction: in a 1-liter four-necked flask, 160.0 grams (1.70 moles) of phenol and 12.5 grams (0.05 moles) of bisphenol-S were dissolved in 500 milliliters of THF, and 1.8 grams of Atoms (41.4 grams) of sodium metal were heated up to 61° C. in 1 hour after the input was completed, and continued to stir at 61 to 68° C. for 6 hours to prepare a mixed solution of sodium phenate. While cooling below 25°C and stirring, this solution was dripped into 580 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com