Combined gas-phase pre-doping and neutron irradiation doping area fused silicon monocrystal production method

A production method and pre-doping technology, applied in the direction of single crystal growth, self-zone melting method, chemical instruments and methods, etc., can solve the problems affecting the development of the zone melting single crystal industry, long production cycle, high production cost, etc., and achieve shortening Channel occupancy time and radiation doping processing production cycle, the effect of increasing production capacity and reducing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific examples are given below to further illustrate how the present invention is realized.

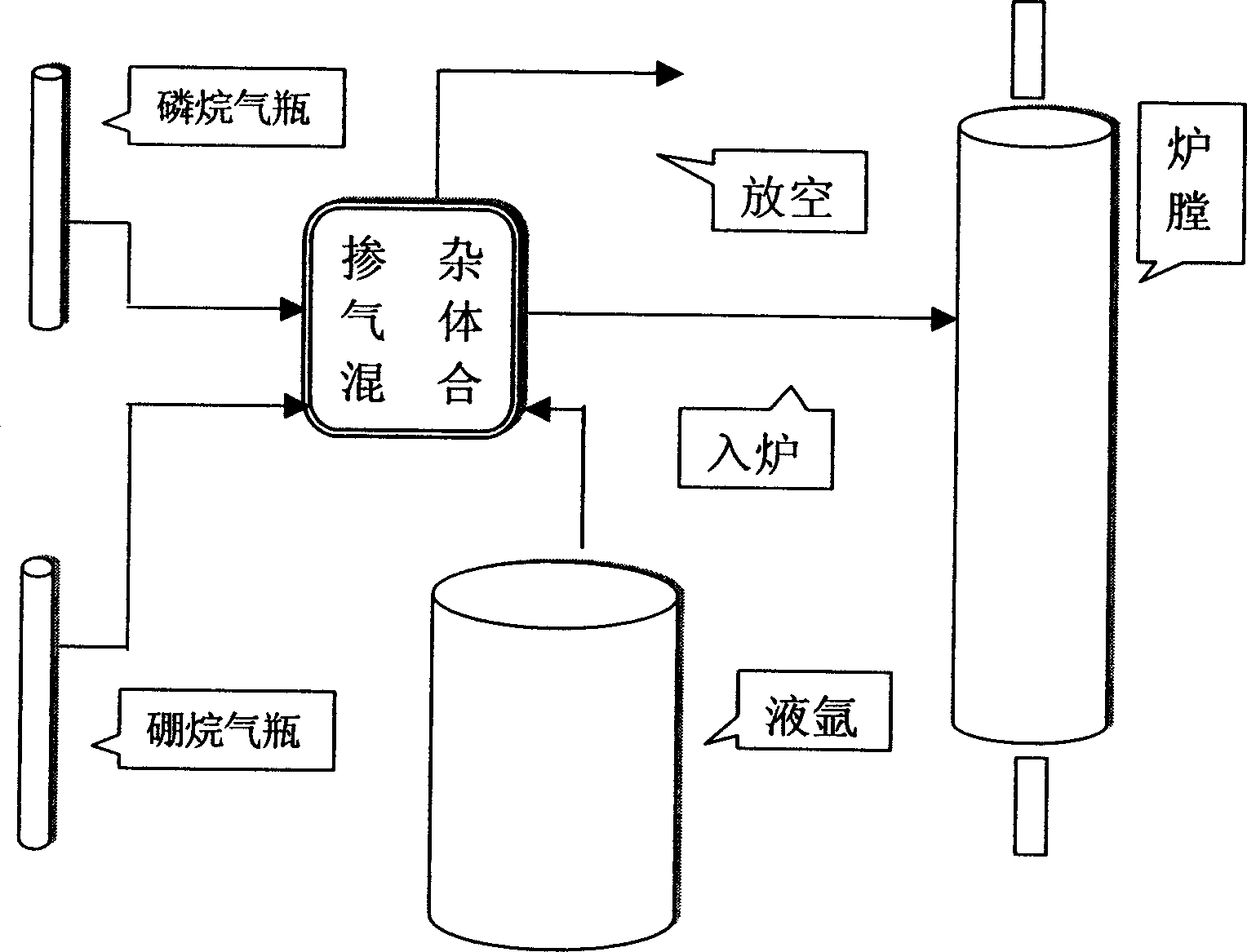

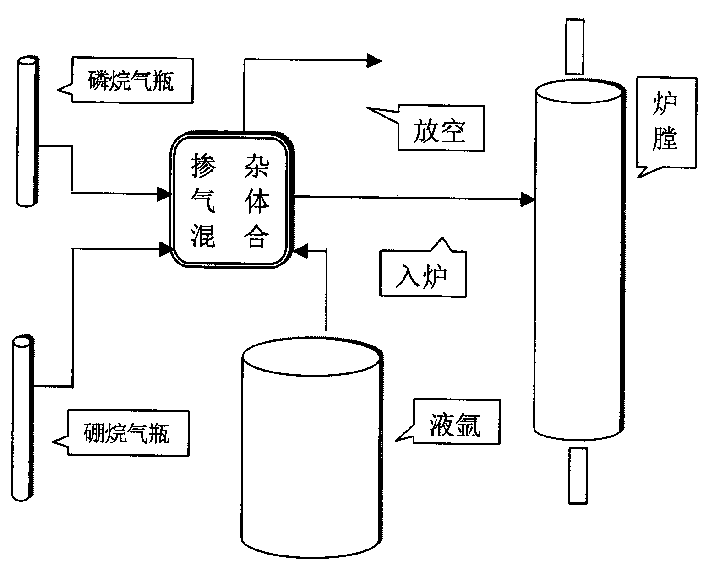

[0034] 1. First carry out gas phase pre-doping, the example of gas phase pre-doping part is as follows:

[0035] 1) The main equipment and raw materials for the production of molten silicon single crystal in the gas phase doping area:

[0036] Zone Furnace: Model: FZ-14-1, FZ-30; Doping Controller: Model: 0154E

[0037] Polysilicon: primary material: base boron ≥ 9000Ω·cm base phosphorus ≥ 900Ω·cm

[0038] CFZ material: base boron≥600Ω·cm, base phosphorus≥400Ω·cm

[0039] 2) The specific steps of the production method of the gas-phase pre-doped region molten silicon single crystal:

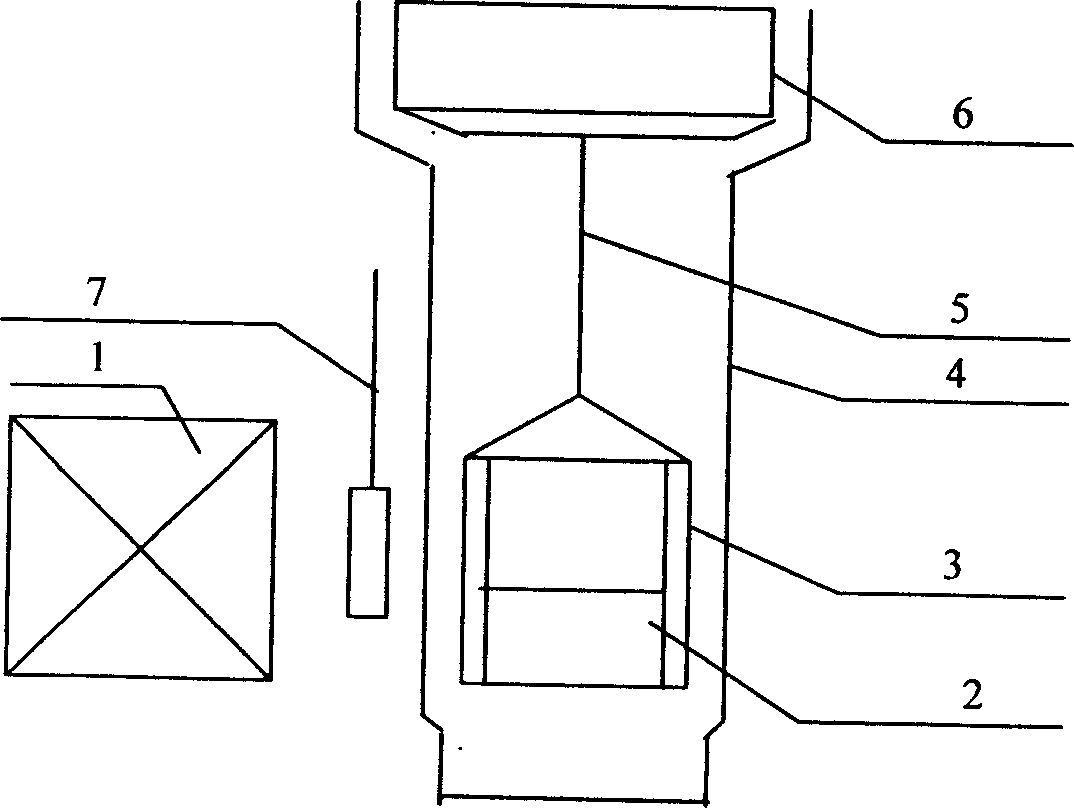

[0040] (1) Furnace loading, evacuation, and argon filling:

[0041] The operator cleans the furnace chamber and coils, reflectors and crystal holders with a vacuum cleaner. Remove the polycrystalline rod from the clean vinyl film and secure the polycrystalline rod in the crystal hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com