Fabrication method of sic-based hemt device

A device and thin film technology, which is applied in the field of SiC-based high-mobility transistor device preparation, can solve the problems of low impurity diffusion coefficient, large crystal damage, and insufficient mobility, so as to improve mobility and reduce lattice damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

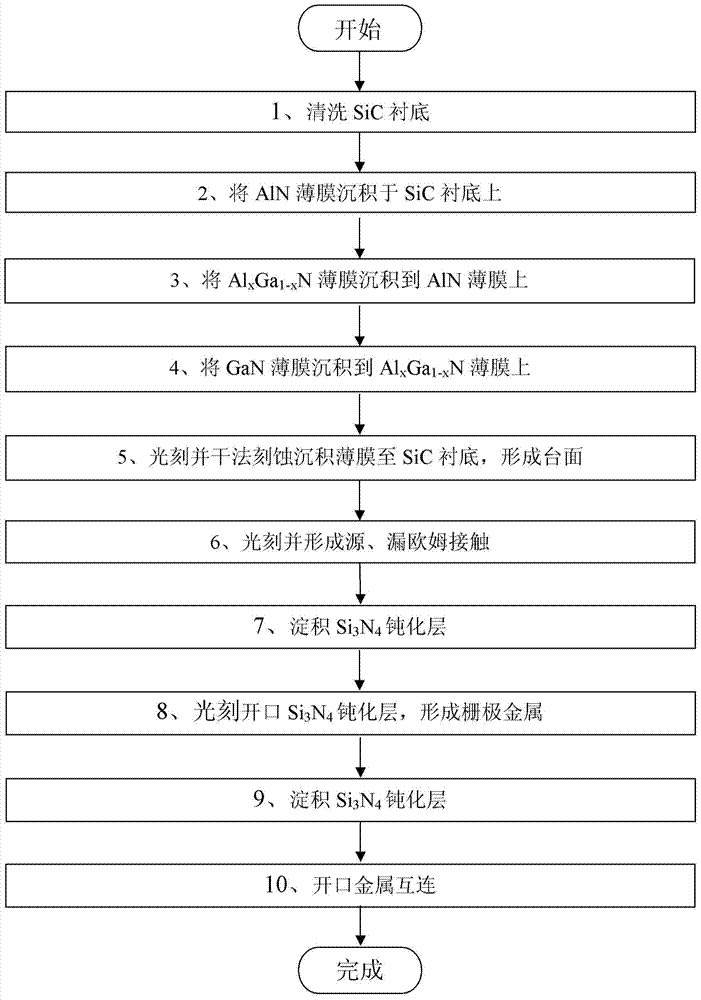

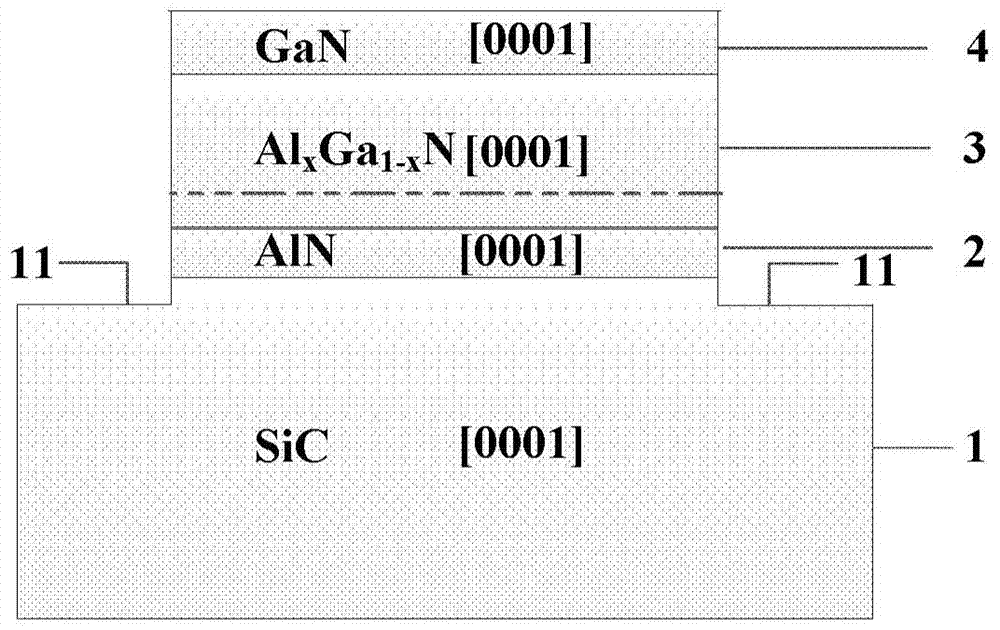

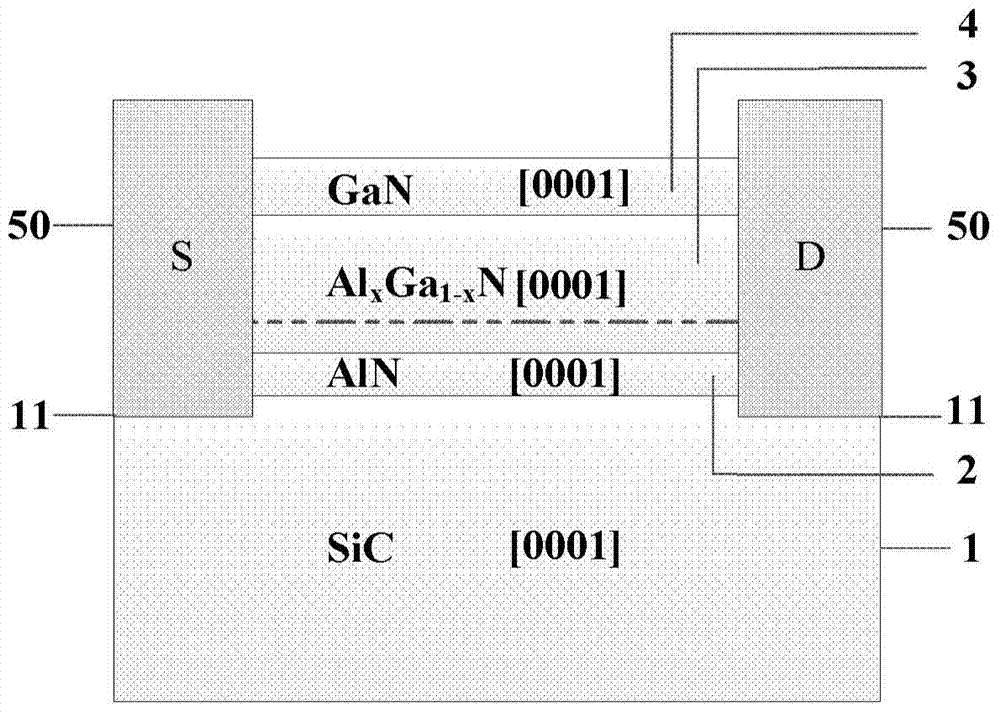

[0025] see figure 1 and refer to Figure 2-Figure 7 , the invention provides a method for preparing a HEMT device based on a SiC material, comprising the following steps:

[0026] Step 1: cleaning the SiC substrate 1, specifically:

[0027] a. Use acetone and ethanol to ultrasonically clean 3 times in sequence, and then rinse with deionized water.

[0028] b. Boiling the SiC substrate 1 after organic ultrasonication in concentrated sulfuric acid and hydrogen peroxide solution for at least 10 minutes.

[0029] c. Boil the substrate 1 that has been boiled with concentrated sulfuric acid for more than 10 minutes in sequence with No. 1 liquid and No. 2 liquid, then rinse it with deionized water and blow it dry with nitrogen for later use. The No. 1 liquid is ammonia water, hydrogen peroxide and The mixed solution of deionized water, by volume ratio ammonia water: hydrogen peroxide: deionized water=1:2:5, the No. 2 liquid is the mixed solution of hydrochloric acid, hydrogen pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com