Formulations for neutralization of chemical and biological toxants

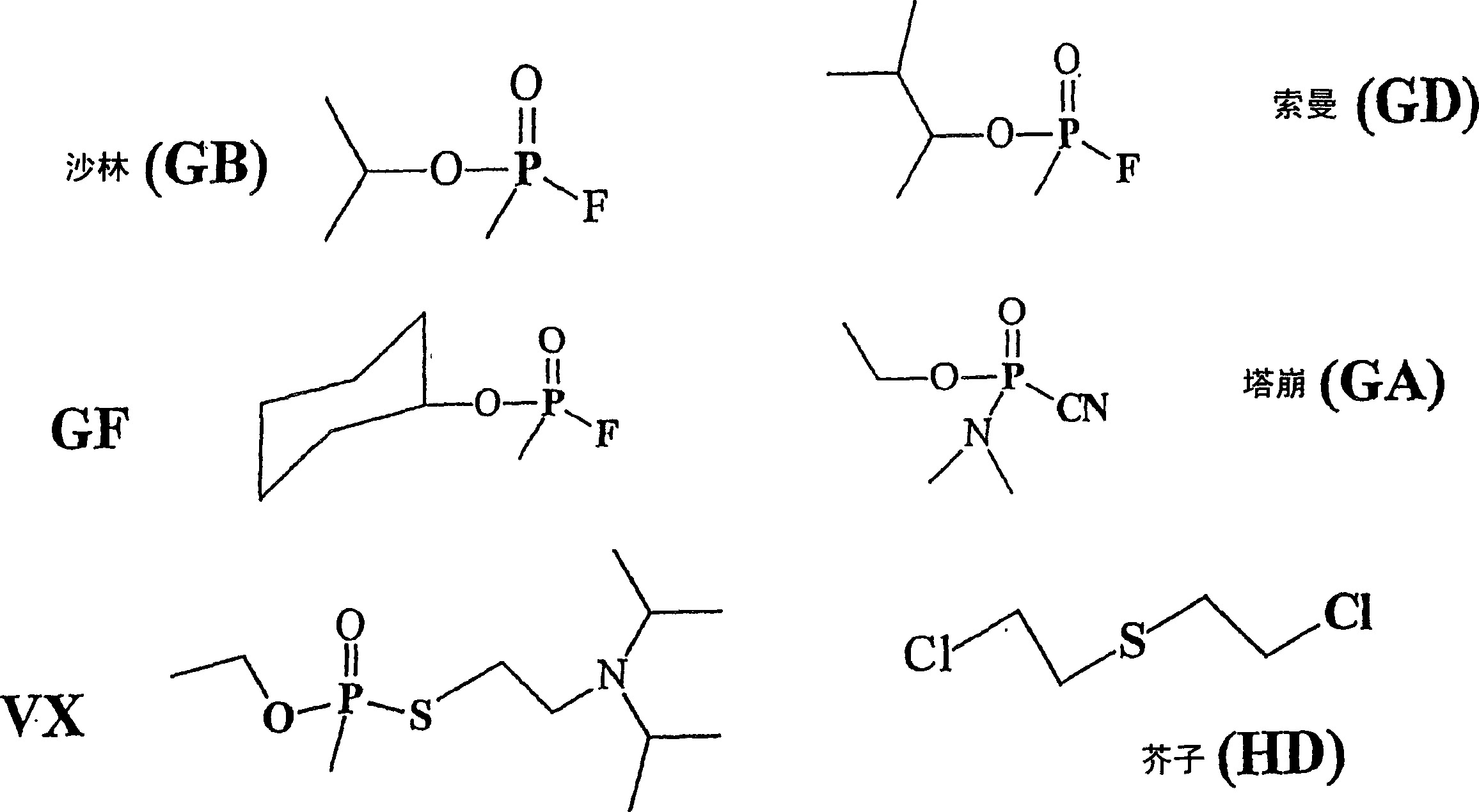

A technology for preparations and poisons, which is applied in the field of materials for neutralizing chemical and biological compounds or reagents, and can solve problems such as the ineffectiveness of GD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

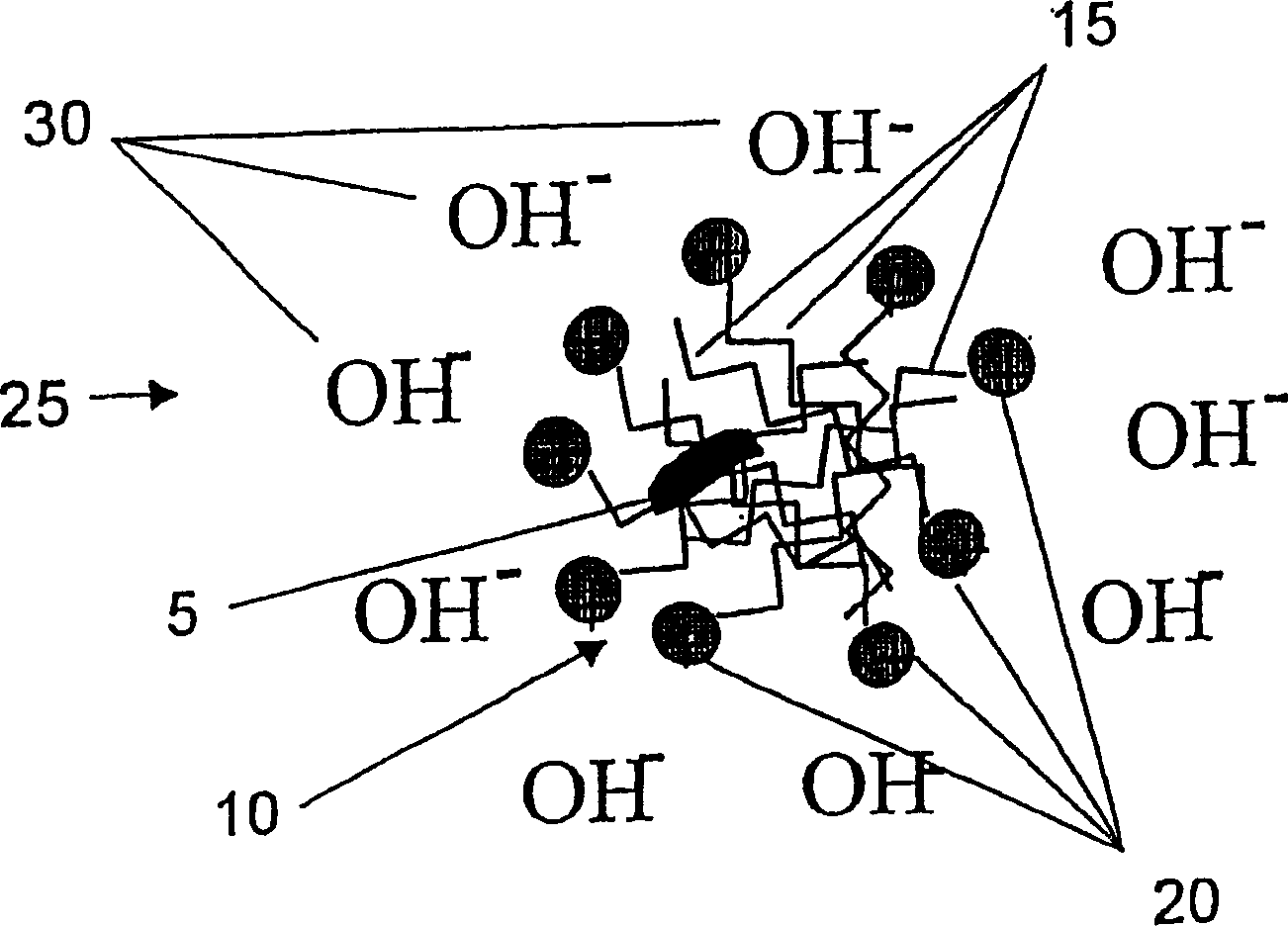

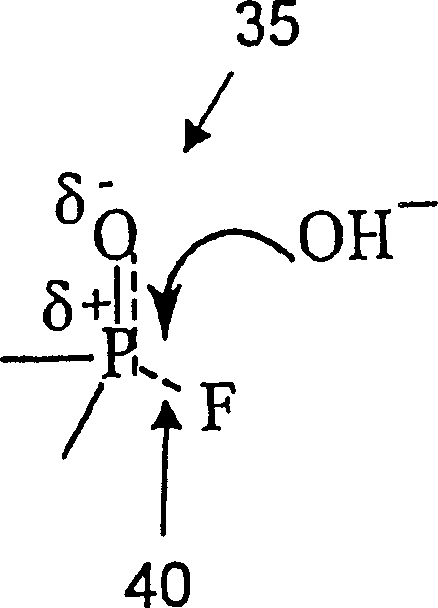

Method used

Image

Examples

Embodiment 1 and Embodiment 2

[0178] The following two examples describe how to make two foam formulations in accordance with the present invention. Hereinafter, examples of test results obtained by using the foam made in accordance with the principles of the present invention are described. Although the sequence of steps shown in Example 1 and Example 2 represents the preferred embodiment of the present invention, the specific sequence described here is not necessary to accomplish the purpose of the present invention. Example 1: Mix the following materials in 100ml water 3.84% by weight WITCO ADOGEN 477 TM (50%)-cationic hydrotrope 2.0 wt% alcohol mixture (36.4 wt% isobutanol, 56.4 wt% diethylene glycol monobutyl ether, 7.3 wt% C 12-14 , Dodecanol / tetradecanol compound)-long-chain fatty alcohol 0.2% by weight JAGUAR 8000 TM Polymer-water-soluble polymer hydrochloric acid (adjust the pH to about 6.5 to increase the dissolution of the polymer) Example 2: The following materials were mixed in 100 ml of water in ...

Embodiment 3

[0194] Example 3. Foam preparation steps

[0195] In the examples below, Variquat 80MC is benzyl (C 12 -C 16 ) A mixture of alkyl dimethyl ammonium chlorides; Adogen 477 is pentamethyl tallow alkyl trimethylene diammonium dichloride; and Jaguar 8000 is guar gum, 2 hydroxypropyl ether.

[0196] 1. Pour 18L of deionized water into a large glass bottle with the largest stirring rod that can be used.

[0197] 2. Add 691.2g of Adogen 477 (Witco) [hydrotrope]. Rinse for weighing 477w / H from glass bottles 2 O's beaker, add the lotion back to the glass bottle.

[0198] 3. Add 360 g of alcohol mixture 1 (36.4% isobutanol; 56.4% DEGMBE; 7.3% dodecanol). Pay attention to the pH and continuously measure the pH throughout the steps.

[0199] 4. Add 36g of Jaguar 8000 [water-soluble polymer]. Add Jaguar 8000 slowly to avoid lumps; add gently and slowly from the spatula. After adding all the Jaguar8000, stir for 15 minutes. When Jaguar dissolves, the pH should rise. Note: This polymer is used to...

Embodiment 5

[0209] Myristyl alcohol. Example 5. Field demonstration of foal formulation

[0210] Field experiments were conducted at the U.S. Army Dugway Test Base in Utah to determine the effectiveness of foam formulations to kill bacterial spores on common office materials. Six kinds of test boards (16"×16") have been built and tested. The test panel consists of ceiling tiles, painted wall panels, carpets, painted metal, office partitions and concrete. These slabs (except for concrete) are placed in a vertical position. Spray with B. globigii spore suspension, let it dry overnight, and sample the initial spore concentration for testing. The concentration of the formulation sprayed on each plate is approximately 100 ml / square meter surface area. The foam formulation (pH 8.0) was sprayed on the surface of the test panel and left overnight. After approximately 20 hours, the test panel was sampled to test for viable spores. Repeat the test every day for four consecutive days.

[0211] The daily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com