Methallyl chloride synthetic process and apparatus thereof

A technology of methallyl chloride and synthesis process, which is applied in the field of synthesis process and equipment of organic chlorinated compounds, can solve the problems of difficult separation, low loss, inability to obtain high-purity products and rectification at the same time, and achieves guaranteed The effect of high yield and improved reaction efficiency

Inactive Publication Date: 2003-11-19

刘德全

View PDF1 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the crude chloride contains light components and heavy components, wherein the light components contain 4 to 5% dimethyl vinyl chloride, which has a similar boiling point and relative volatility to methallyl chloride, so it is similar to methallyl chloride. Allyl chloride is extremely difficult to separate, and the double-tower process cannot simultaneously obtain high-purity products and low losses in rectification

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0053] Methallyl Chloride %

Embodiment 2

[0055] serial number

[0056] temperature

Embodiment 3

[0058] The crude chloride is discharged from the tower kettle (6 towers), containing about 100-200ppm of HCl, after neutralization, the HCl content in the chloride is ≈0 (actually not detected)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

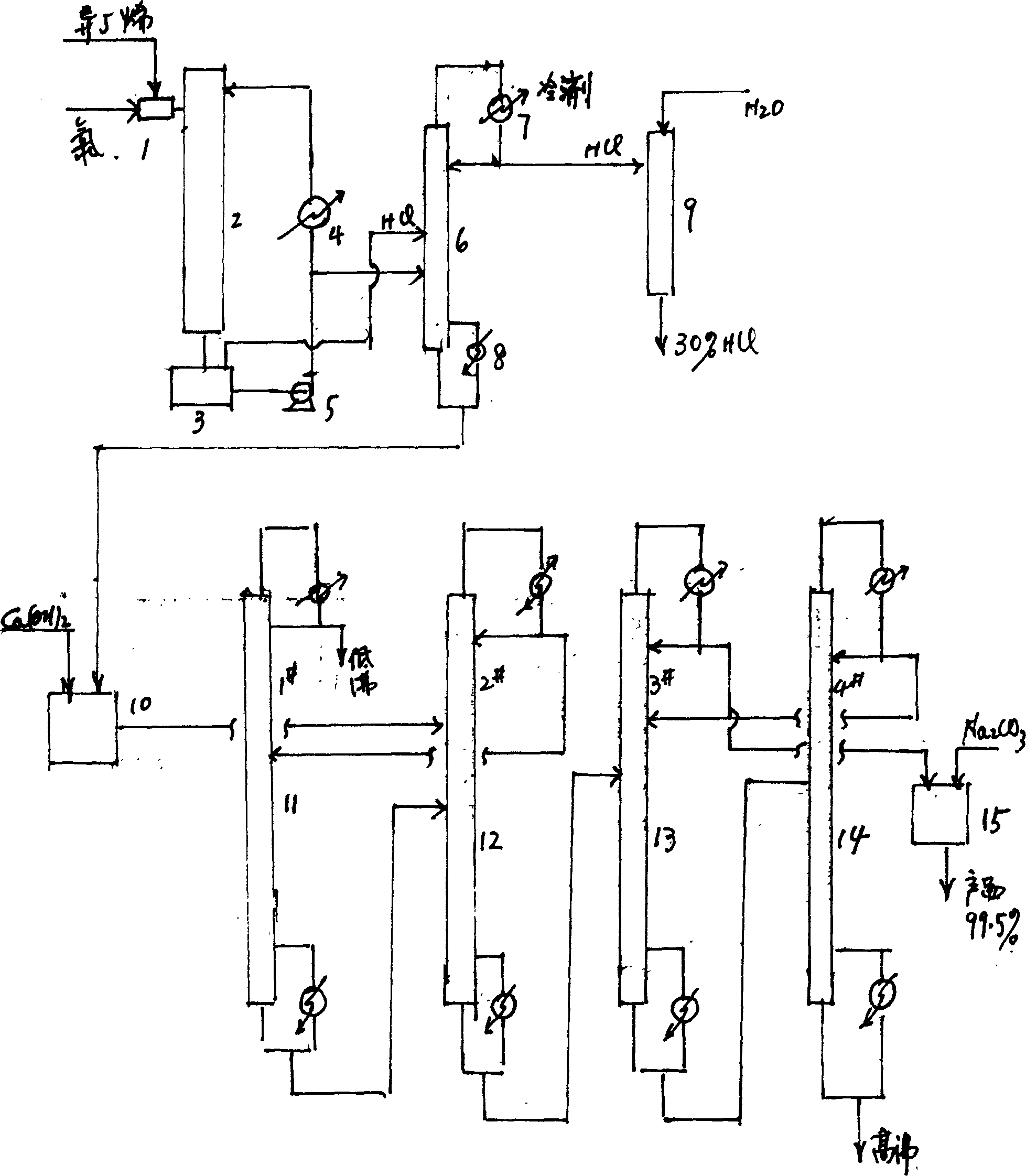

A process for synthesizing methallyl chloride includes such steps as gas-phase mixing of chlorine with isobutylene, separating chloride from HCl, neutralizing, continuous multi-tower vacuum distilling, and neutralizing. Its apparatus features that the cooling system is separated from reactor system. Its advantage is high product purity (more than 99.5%).

Description

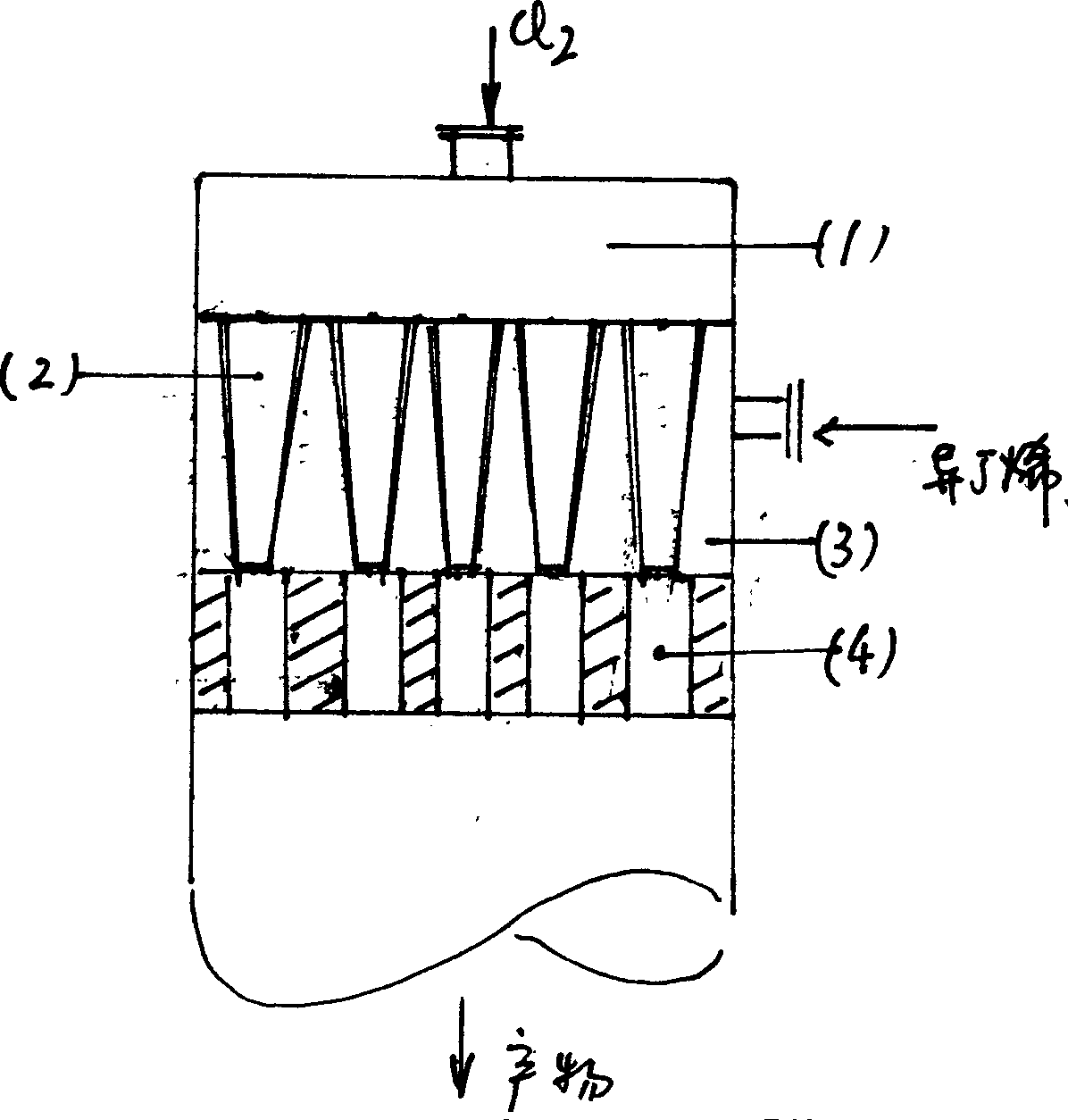

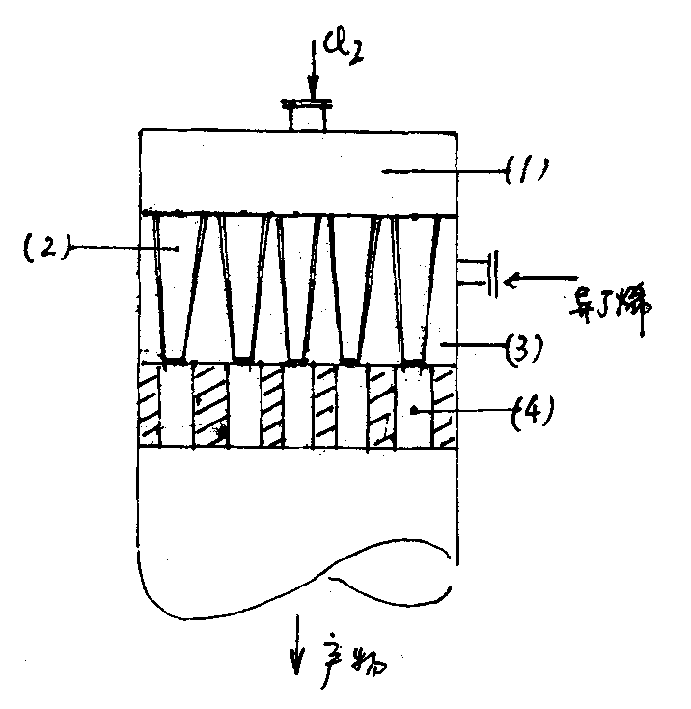

(1) Technical field: [0001] The invention relates to a synthesis process and equipment for organic chlorinated substances. (2) Background technology [0002] The production of methallyl chloride (also known as methallyl chloride) is a gas-phase reaction of chlorine gas and isobutylene. Generally, the reaction temperature is normal temperature (30-100°C) and the reaction pressure is normal pressure (9 atmospheres) in a set of cooled tubular reactor. In order to avoid the deep chlorination reaction of methallyl chloride, isobutylene is slightly excessive. Feedstock was fed into the reactor through two outlet nozzles. (Japanese Laid-Open Patent Gazette, Japanese Unexamined 50-62910) The mixer reported is a single nozzle. The mixer of single spray nozzle then along with the enlargement of industrial scale, produces amplification effect and reduces yield, and generally speaking yield can drop from 85% to 75-78% or lower. [0003] The reacted m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C17/02C07C21/067

Inventor 刘德全

Owner 刘德全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com