Production of alcohol by fermenting by yeast tolerant to high concentrated sugar and alcohol

An alcohol fermentation, high concentration technology, applied in fermentation, biofuel and other directions, can solve the problems of low alcohol concentration, reduce the utilization rate of sugar, curb yeast growth and fermentation, etc., to reduce production costs, increase alcohol content, and facilitate implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

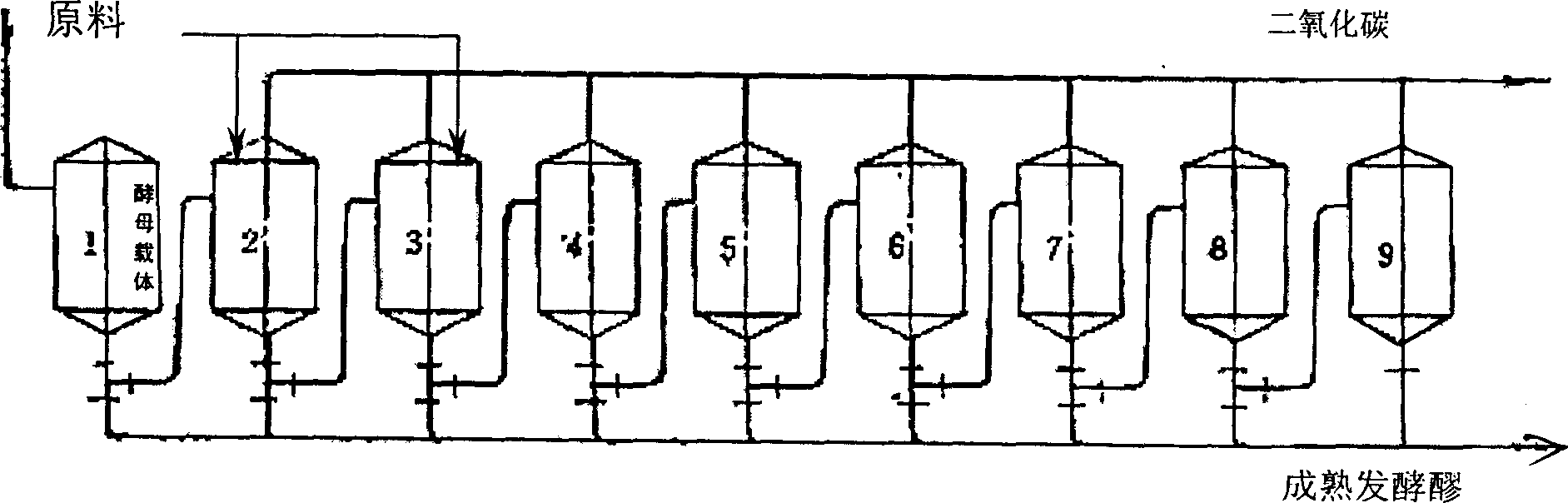

Image

Examples

Embodiment 1

[0017] The 1912 bacterial strain was cultivated according to the conventional liquid seed culture method of microbial fermentation, with wort culture medium (take the wort juice of the brewery at 10 Pomi degrees), and after a series of cultures such as shake flasks and seed tanks, when each milliliter of culture fluid contained Yeast count reaches 1×10 8 One hour, put 90M into the amount of 1 / 15 of the culture liquid 3 Cultures were carried out in fermenters containing 10-15M 3 Sugar concentration is 10% sterile medium. The temperature was controlled at 28°C, the pH value was controlled at 4.5, and sterile air was maintained continuously or intermittently, that is, 10 minutes at intervals of 1 hour. Check the amount of yeast in the culture solution, and reach 10% yeast per milliliter of culture solution. 8 At one time, add the culture solution containing high concentration of sugar, so that the weight percentage concentration of sugar in the whole culture solution reaches 1...

Embodiment 2

[0019] The specific operation is the same as in Example 1, the difference: the seed culture stage is ventilated for 20 minutes every 1 hour, when the nutrient solution contains yeast 10 8 At one hour, the sugar weight percent concentration of the added culture solution was 23%, and the stirring was kept in intervals or sterile air was passed through for 12 minutes every 2 hours, and the final alcohol volume percent concentration reached 13%.

Embodiment 3

[0021] The specific operation is the same as in Example 1, the difference: the seed culture stage is ventilated for 30 minutes every 1 hour, when the nutrient solution contains yeast 10 8 At one hour, the sugar weight percent concentration of the culture solution added was 30%, kept stirring in the interval or passing sterile air for 20 minutes every 2 hours, and the final alcohol volume percent concentration reached 14%.

[0022] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com