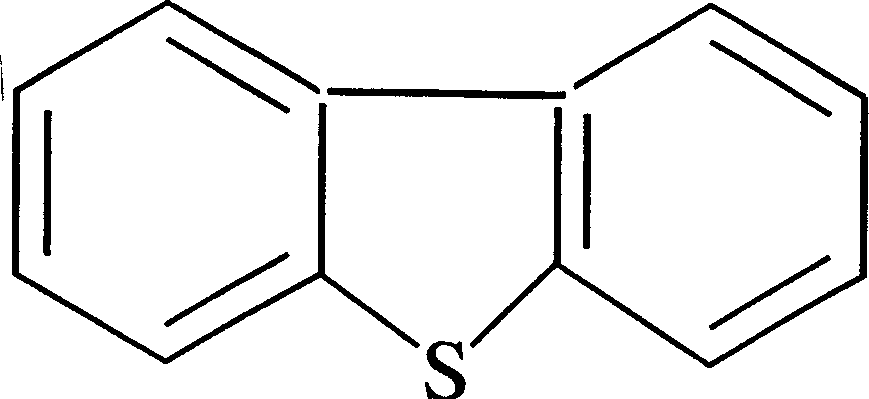

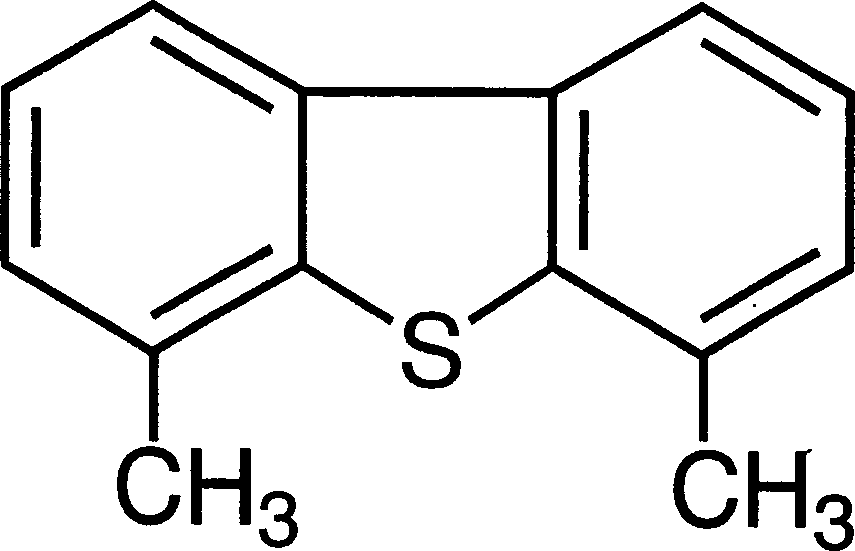

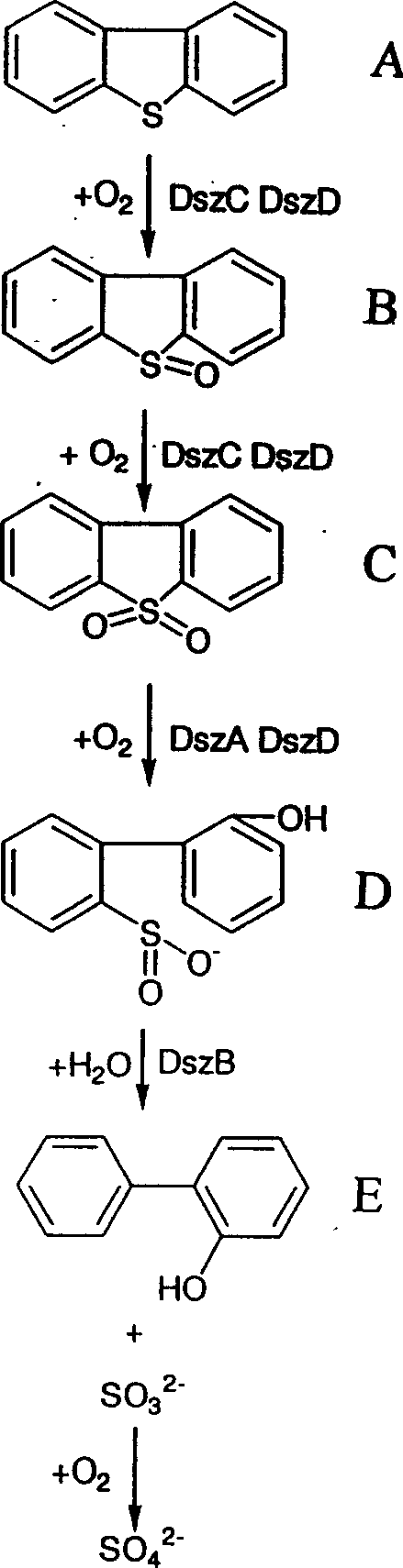

Method for oil desulfuration by using calcium alginate immobilized Diehliumyces pseudomonads R-8

A technology of Pseudomonas and calcium alginate, applied in the petroleum industry, refining hydrocarbon oil, fermentation, etc., can solve the problems of increased process complexity and low desulfurization efficiency, and achieve high activity of immobilized cells, low production cost, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Cultivate the cells in the logarithmic growth phase of Pseudomonas delbrueckii R-8 whose accession number is CGMCC 0570:

[0035] Pick the Pseudomonas delbrueckii R-8 strain cultured on the vegetative slant, add it to a medium with a volume of 25 ml, and cultivate it for 2 days at 30°C and 170r / min, and then culture the Pseudomonas delbrueckii Inoculate the R-8 strain of Pseudomonas delbrueckii into a 500ml Erlenmeyer flask containing 150ml of the above-mentioned medium, culture it on a shaker until the logarithmic growth phase, and centrifuge at 5000rpm for 6min to obtain Pseudomonas delbrueckii R-8 cells; wash it with physiological saline 2 to 3 times, the obtained Pseudomonas delbrueckii R-8 cells were suspended in normal saline and placed in a refrigerator at 4°C; the composition of the medium was as follows: 1000ml deionized water, KH 2 PO 4 2.44g; Na 2 HPO 4 12H 2 O 12.03g; NH 4 Cl 2.0g; MgCl 2 ·6H 2 O 0.4g; CaCl 2 2H 2 O 0.001g; FeCl 3 ·6H 2 O 0.00...

Embodiment 2

[0045] 1. Cultivate the quiescent cells of Pseudomonas delbrueckii R-8 whose accession number is CGMCC 0570:

[0046] Take 0.5 milliliters of glycerol to preserve Pseudomonas delbrueckii R-8 and add it to a medium with a volume of 50 milliliters, cultivate it for 2 days at 30°C and 170 r / min, and then culture the Pseudomonas delbrueckii R-8 -8 strain was inoculated into a 500ml Erlenmeyer flask containing 150ml of the above-mentioned medium, cultured on a shaking table for 2 days, transferred to a fermenter for cultivation to a stationary phase, and was centrifuged at 5000rpm for 6min to obtain Pseudomonas delbrueckii R-8 thalline; Wash with normal saline for 2 to 3 times, suspend the Pseudomonas delbruecki R-8 cells obtained in normal saline, and place them in a refrigerator at 4°C;

[0047] The composition of the medium is as follows: deionized water 1000ml, KH 2 PO 4 2.44g; Na 2 HPO 4 12H 2 O 12.03g; NH 4 Cl 2.0g; MgCl 2 ·6H 2 O 0.4g; CaCl 2 2H 2 O 0.001g; FeCl ...

Embodiment 3

[0057] Repeatedly using the calcium alginate immobilized cells after activation of the proliferation culture obtained in Example 1 to remove sulfur in dibenzothiophene (DBT) in simulated oil (dodecane):

[0058] Take several grams of the calcium alginate immobilized cells (containing 0.2g stem cells) obtained after the proliferation culture activation prepared in Embodiment 1 in a 100ml Erlenmeyer flask, add 5ml proliferation medium and 5ml dodecane (dissolved 1mmol / LDBT), The volume of the water phase accounts for 50% of the total volume of the oil-water phase. React on a shaking table at 30°C and 170r / min. After 24 hours of reaction, pour off the oil-water phase, wash the immobilized cells with normal saline for 3 times, and then add 5ml of fresh proliferation medium and 5ml of dodecane (dissolved 1mmol / L DBT); at 30°C, 170r / min conditions, carry out shaking table reaction; use HPLC to analyze the content of DBT in the oil phase; after 24 hours, repeat the above process, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com