Process for preventing heavy duty optical resistance from collapsing

A technology for heavy industry light and photoresist, applied in photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of reduced production capacity, complex process, and increased production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention discloses a method for preventing the collapse of photoresist in heavy industry, and the method of the present invention will be described below in the form of a preferred embodiment.

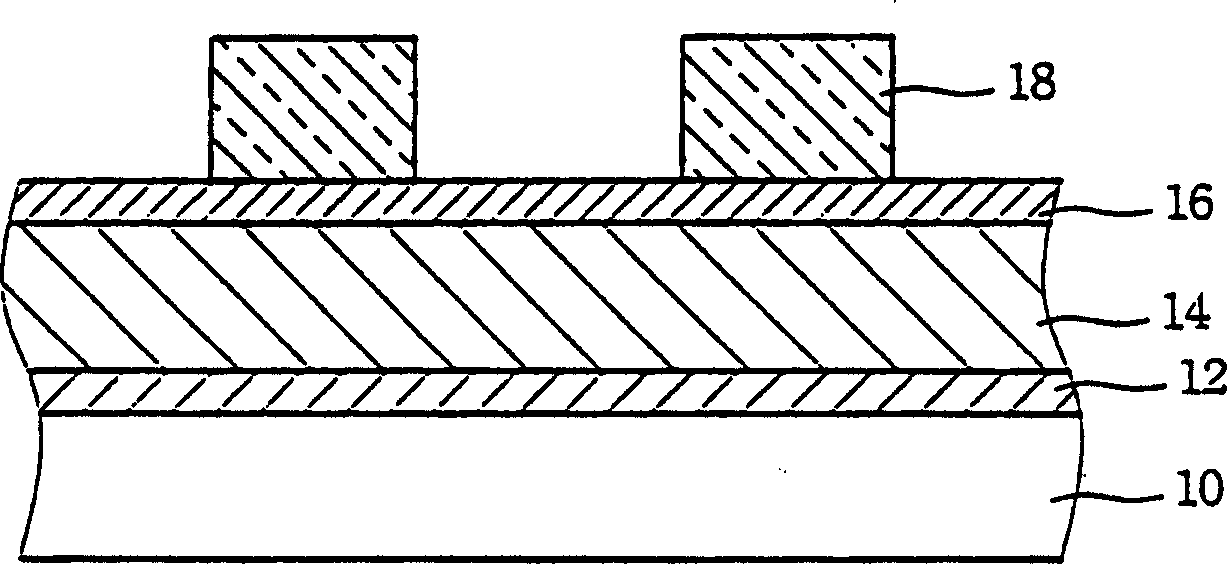

[0022] Please refer to figure 1 , which shows a cross-sectional schematic diagram of a process for forming a gate of a transistor. A gate oxide layer 12 is formed on a semiconductor substrate 10 . Preferably, the gate oxide layer 12 can form a layer of silicon dioxide (SiO 2 ). Next, a polysilicon layer 14 is formed on the gate oxide layer 12 . The polysilicon layer 14 can be formed by chemical vapor deposition with a thickness of about 500-5000 angstroms, preferably 2000 angstroms. Subsequently, an anti-reflective coating (Anti-Reflective Coating, ARC) 16 is covered on the polysilicon layer 14 . Preferably, the anti-reflection coating layer 16 can be deposited on the polysilicon layer 14 by a chemical vapor deposition method of silicon oxynitride (SiON) materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com