Magnesium oxide particle aggregate

A technology of aggregates and magnesia, applied in magnesia, furnaces, heat treatment equipment, etc., can solve the problems that it is difficult to apply and cannot properly evaluate forsterite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

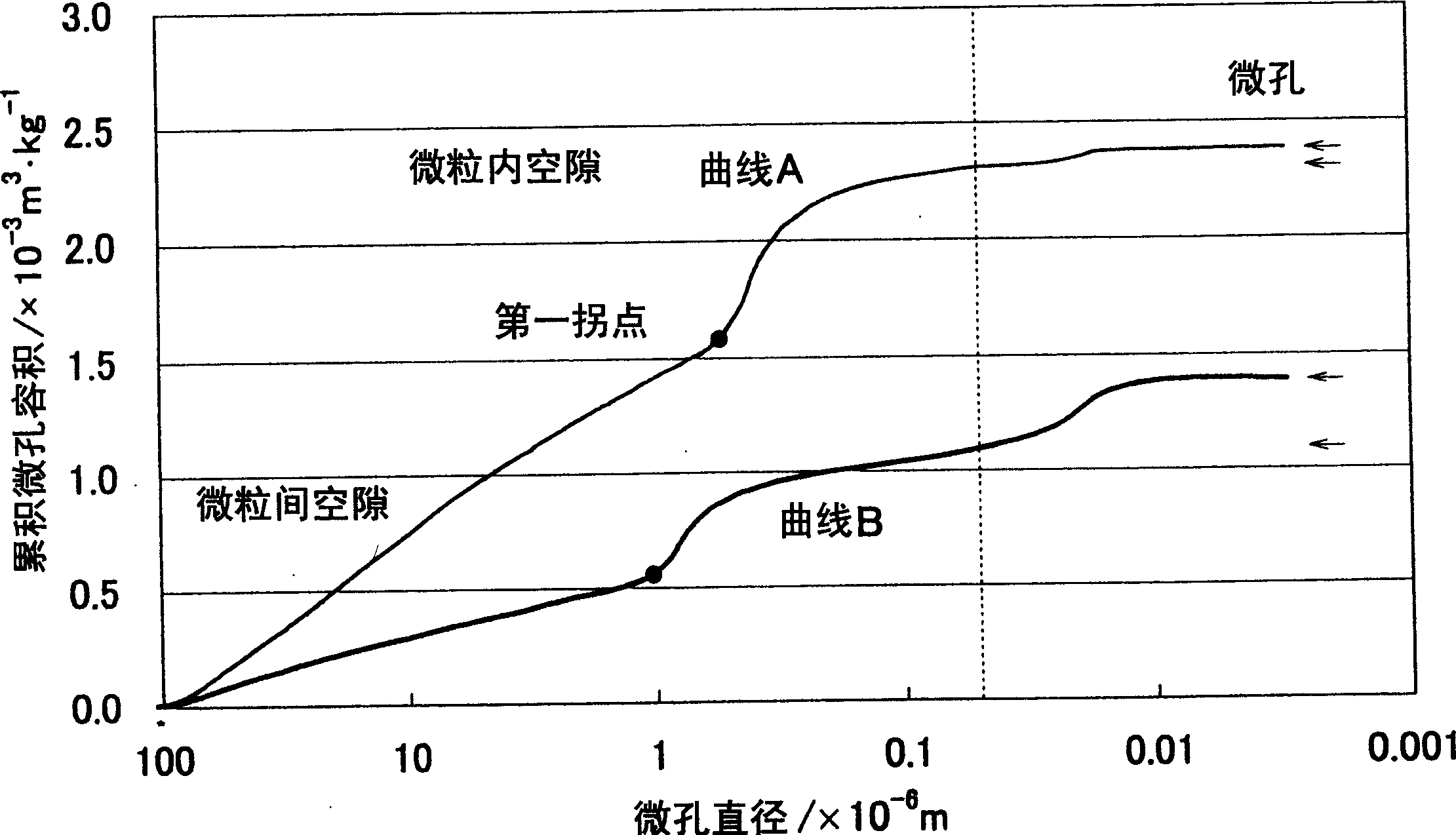

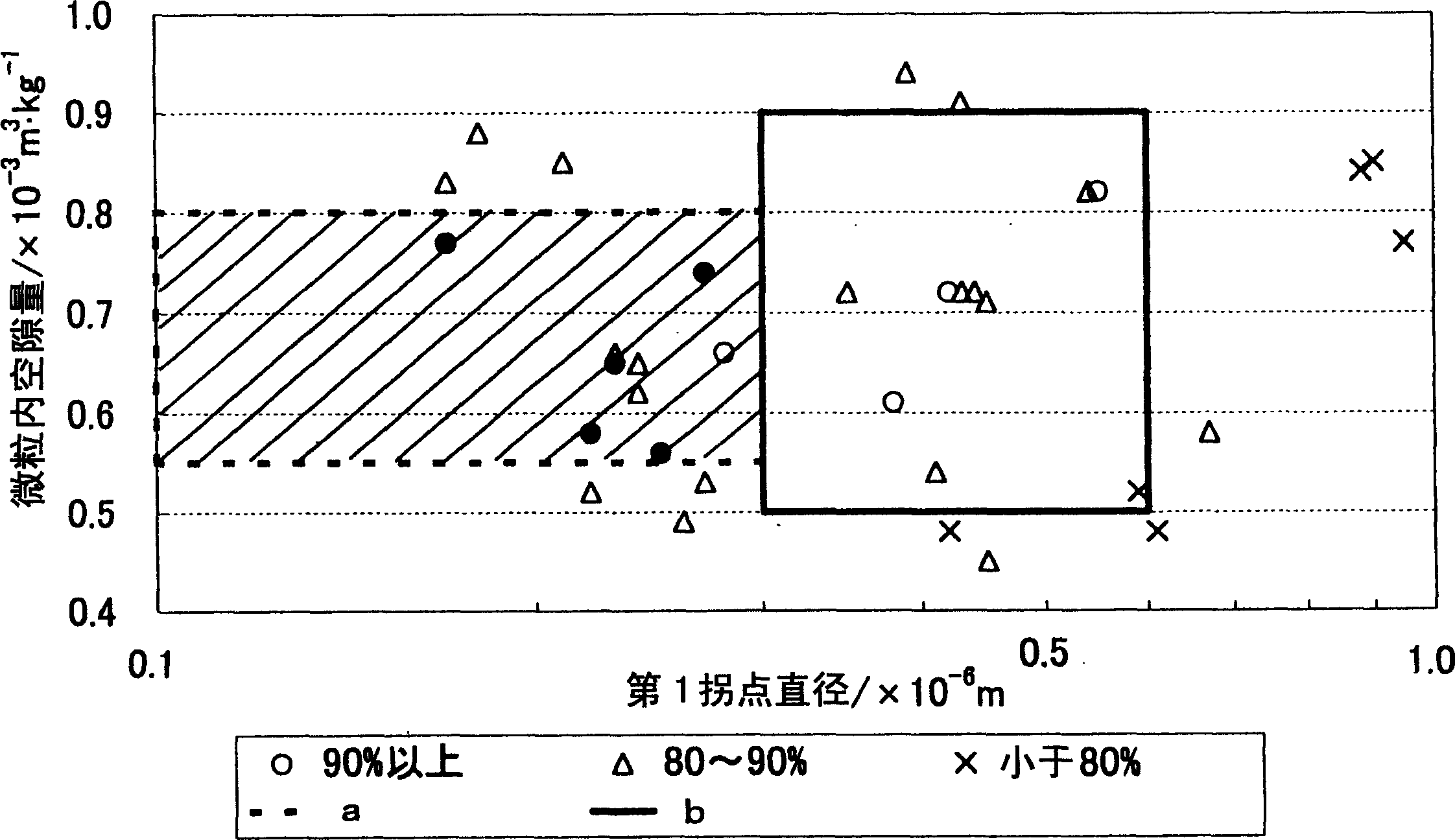

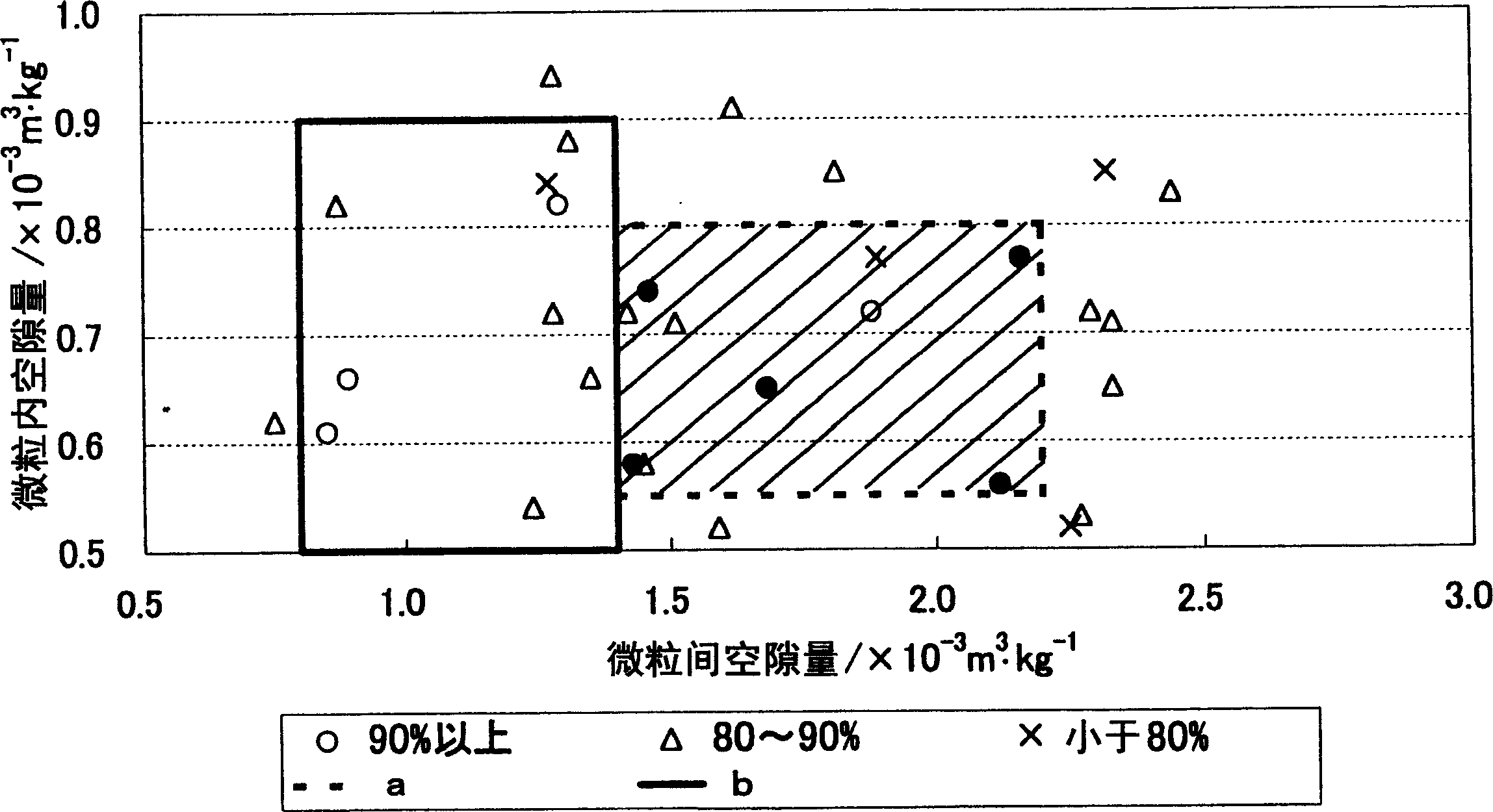

Method used

Image

Examples

Embodiment 1

[0062] At a concentration of 2.0mol·kg -1 Add potassium hydroxide slurry to the magnesium chloride solution, so that the concentration of magnesium hydroxide after the reaction is 1.2mol kg -1 , the mixed solution was reacted in an autoclave at 150°C for 3 hours to obtain a BET specific surface area of 8.2×10 3 m 2 kg -1 of magnesium hydroxide. Using a rotary kiln at temperatures of 800°C, 950°C, and 1050°C, respectively, firing for 1 hour and then pulverizing with an impact mill to produce three kinds of aggregates of magnesium oxide particles with different degrees of firing. Afterwards, in order to make the particle aggregation form fall within the scope of the present invention, the three kinds of magnesium oxide particle aggregates were mixed at a mixing ratio of 30:40:30 to obtain magnesium oxide particle aggregates.

Embodiment 2

[0064] Using a rotary kiln, magnesite was fired at 1100°C for 1 hour to obtain a BET specific surface area of 5.2×10 3 m 2 kg -1 of magnesium hydroxide. Add the magnesium oxide to water, and make the slurry concentration 2mol·kg -1 , and reacted at 90°C for 2 hours to obtain a BET specific surface area of 7.5×10 3 m 2 kg -1 of magnesium hydroxide. Then, they were fired in a rotary kiln at 980° C. for 0.2 hours, 0.5 hours, 0.8 hours, and 2 hours, respectively, and then pulverized with an impact mill to obtain aggregates of magnesium oxide particles with different degrees of firing. Afterwards, in order to make the particle aggregation form fall within the scope of the present invention, the four kinds of magnesium oxide particle aggregates were mixed at a mixing ratio of 25:30:15:30 to obtain the magnesium oxide particle aggregate of Example 2.

Embodiment 3

[0066] Add slaked lime to the brine so that the concentration of magnesium hydroxide after the reaction is 1.2mol kg -1 , and stirred at 600 rpm, and reacted at 80° C. for 2 hours. Then, the magnesium hydroxide obtained by filtering, washing and drying with a filter press was fired at 900°C for 1 hour in a rotary kiln to obtain a BET specific surface area of 20.6×10 3 m 2 kg -1 of magnesium hydroxide. Add the magnesium oxide to water, and make the slurry concentration 3mol·kg -1 , then add magnesium chloride relative to magnesium oxide 2mol%, and react the mixed solution at 80°C for 2 hours to obtain a BET specific surface area of 11.0×10 3 m 2 kg -1 of magnesium hydroxide. Next, use a muffle furnace to burn at a furnace temperature of 1200°C for 2 hours, 3 hours, and 4 hours, respectively, and then pulverize with an impact mill to obtain magnesium oxide particles with different firing degrees. Aggregates. Then, in order to make the particle aggregation form fall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com