Equipment and method for preparing fibre-optical microprobe by siphon lifting method corrosion

A micro-probe and siphon technology, applied in measurement devices, scanning probe technology, scanning probe microscopy, etc., can solve the problems of large human injury, strong HF acid corrosion, and unenvironmental protection, and it is easy to achieve preparation conditions. Control, good repeatability and ideal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

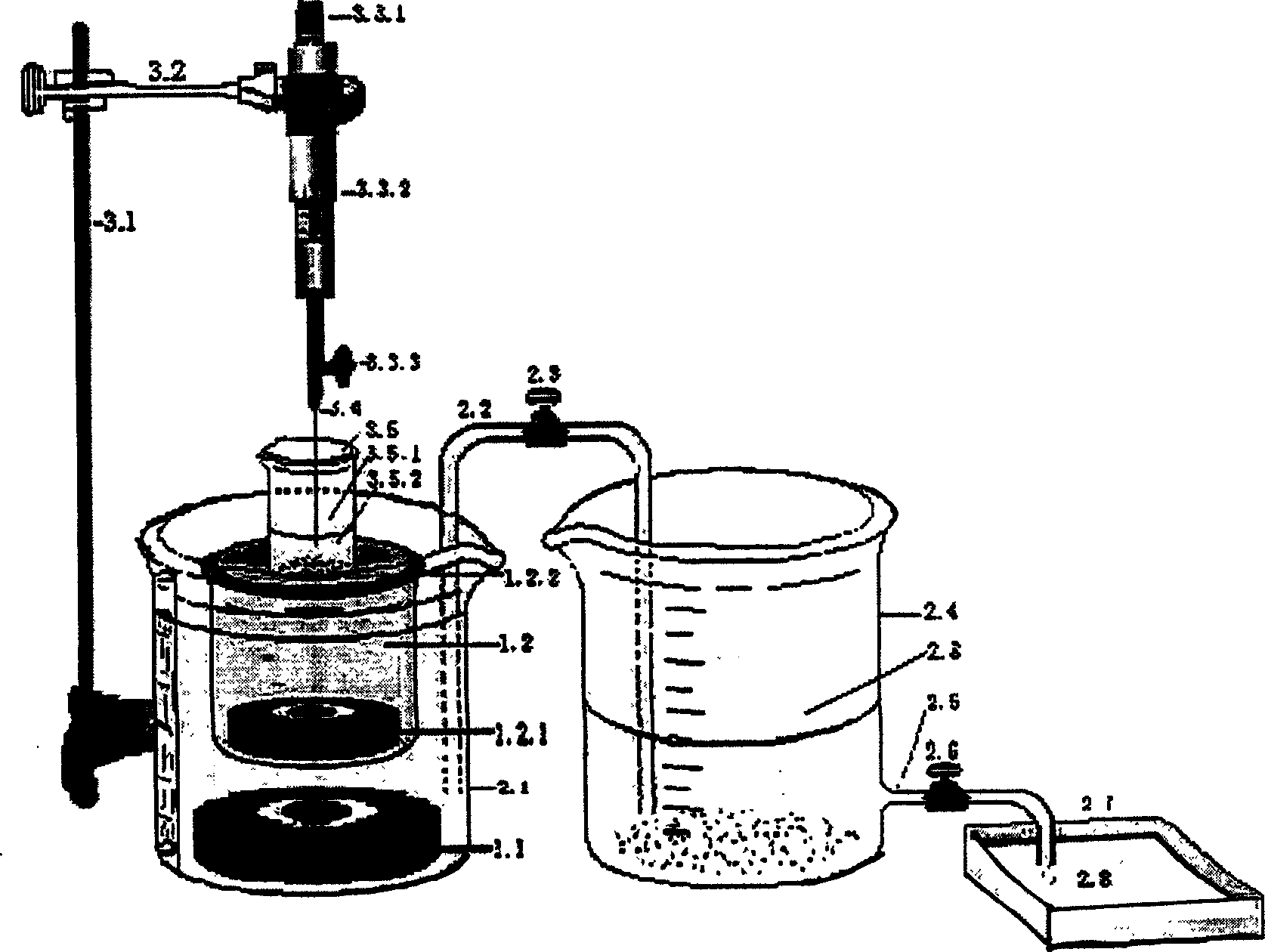

[0014] The device adopts magnetic force to position the suspended object stage, realizes gentle and variable lifting corrosion through siphon, and realizes a novel method for preparing optical fiber probe with multiple advantages. The device is composed of three main parts and an auxiliary part, namely the magnetic positioning of the suspended load, the siphon level control, and the optical fiber probe position control three main parts, and the optical lever initial speed measurement auxiliary part. The magnetic positioning suspended load system consists of a positioning magnet and a magnetic suspension stage; the siphon level control system consists of the main container (beaker), siphon tube, siphon flow rate control valve, attached container (beaker), drain pipe, drain control valve and The drainage tank is composed of; the optical fiber probe position control system is composed of an iron stand (with bracket), a spiral micrometer, an optical fiber fixing clip and a corrosive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com