Solid phase adsorption air pollutant sampler and its producing method

A technology of air pollutants and solid-phase adsorption, applied in the direction of sampling devices, etc., can solve the problems of low absorption efficiency, cumbersome operation, inconsistency, etc., and achieve the effect of small wind resistance and complete absorption reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

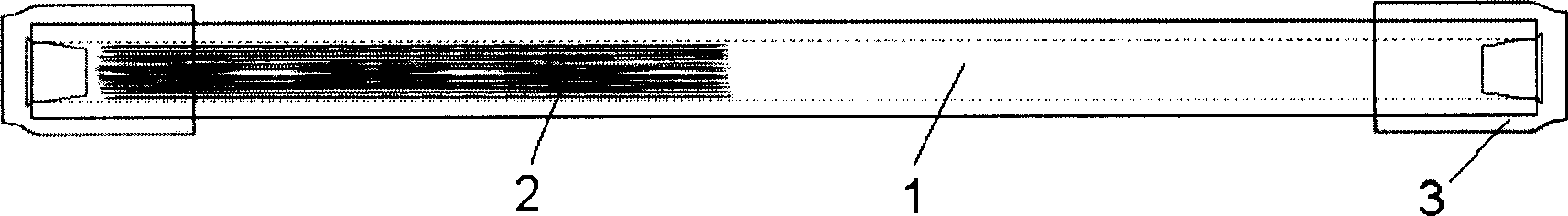

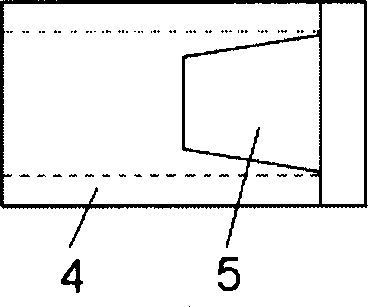

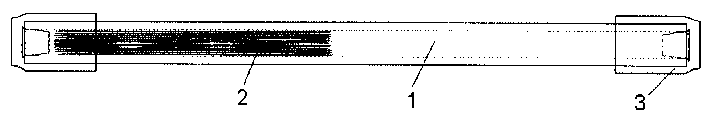

Image

Examples

Embodiment Construction

[0023] (1) Sampling tube for ammonia in the air:

[0024] 1. Glass tube production: Use a caliper to select a glass tube with an inner diameter of 5.0±0.1mm and an outer diameter of 8±0.2mm, and use a glass knife to cut it into a glass tube with a length of 20cm. Grind both ends of the tube with fine corundum, and use a fine emery wheel to chamfer the outer circle of the tube mouth, then put an alcohol blowtorch to burn red, the tube mouth becomes soft, cool down, make the inner and outer openings of both ends of the glass tube smooth, and make the silicone rubber stopper The rear sealing effect is better. Clean the glass tube in an ultrasonic cleaner, rinse it with deionized water, and dry it at 105°C.

[0025] 2. Surface modification of polypropylene tow:

[0026] The preparation of silicon dioxide coating liquid: take by weighing 40g sodium silicate (Na 2 SiO 3 9H 2 O A.R.) Add 960mL deionized water, microwave for 1 minute, after dissolving, add 1000mL deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Total surface area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com