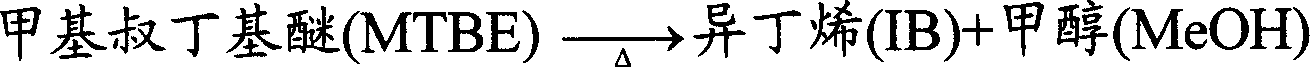

Method of producing isobutene joint producing dimetylether and dipolyisobutene

A dimerized isobutylene and isobutylene technology, which is applied in chemical instruments and methods, preparation of organic compounds, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of low purity of dimerized isobutylene products, increased equipment costs and operating costs, etc. problem, to achieve the effect of improving conversion rate, saving equipment investment and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the catalyst used in embodiment 1~embodiment 6 is as follows:

[0045] Dissolve 47 grams of analytically pure concentrated sulfuric acid (concentration 98%) in distilled water to prepare 200 ml of sulfuric acid aqueous solution, and 150 ml of gamma-Al 2 o 3 The carrier is immersed in the above solution for 2 hours, the residual liquid is filtered off, the impregnated carrier is dried at 120°C for 4 hours, and then roasted at 550°C for 4 hours, and then the catalyst is continued to be immersed in the above sulfuric acid aqueous solution for 2 hours. After drying at ℃ for 4 hours, and then calcining at 550℃ for 4 hours, the sulfate content in the prepared catalyst was 22.12wt.%.

Embodiment 7

[0046] The preparation method of catalyst used in embodiment 7 is as follows:

[0047] Dissolve 88 grams of analytically pure ammonium sulfate in distilled water to prepare 200 ml of ammonium sulfate aqueous solution, and 150 ml of γ-Al 2 o 3 The carrier was immersed in the above solution for 2 hours, and the raffinate was filtered off. The impregnated carrier was dried at 120°C for 4 hours, and then calcined at 550°C for 4 hours. The sulfate content in the prepared catalyst was 22.08wt.%.

Embodiment 8

[0048] The preparation method of catalyst used in embodiment 8 is as follows:

[0049] 83 grams of analytically pure ferrous sulfate (FeSO 4 7H2O) was dissolved in distilled water to make 200ml ferrous sulfate aqueous solution, and 150ml γ-Al 2 o 3 The carrier is immersed in the above solution for 2 hours, the residual liquid is filtered off, the impregnated carrier is dried at 120°C for 4 hours, and then calcined at 250°C for 4 hours, and then the catalyst is continued to be immersed in the above ferrous sulfate aqueous solution for 2 hours, After drying at 120°C for 4 hours, and then calcining at 250°C for 4 hours, the sulfate content in the prepared catalyst was 21.97wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com