Modified method of pressure swing adsorption

A pressure swing adsorption and adsorption bed technology, applied in the field of pressure swing adsorption, can solve the problems affecting the production efficiency and product gas recovery rate of the multi-bed pressure swing adsorption process, the increase of investment in the pressure swing adsorption system, and the increase of the pressure swing adsorption system. To achieve the effect of shortening cycle time, long pressure equalization times and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

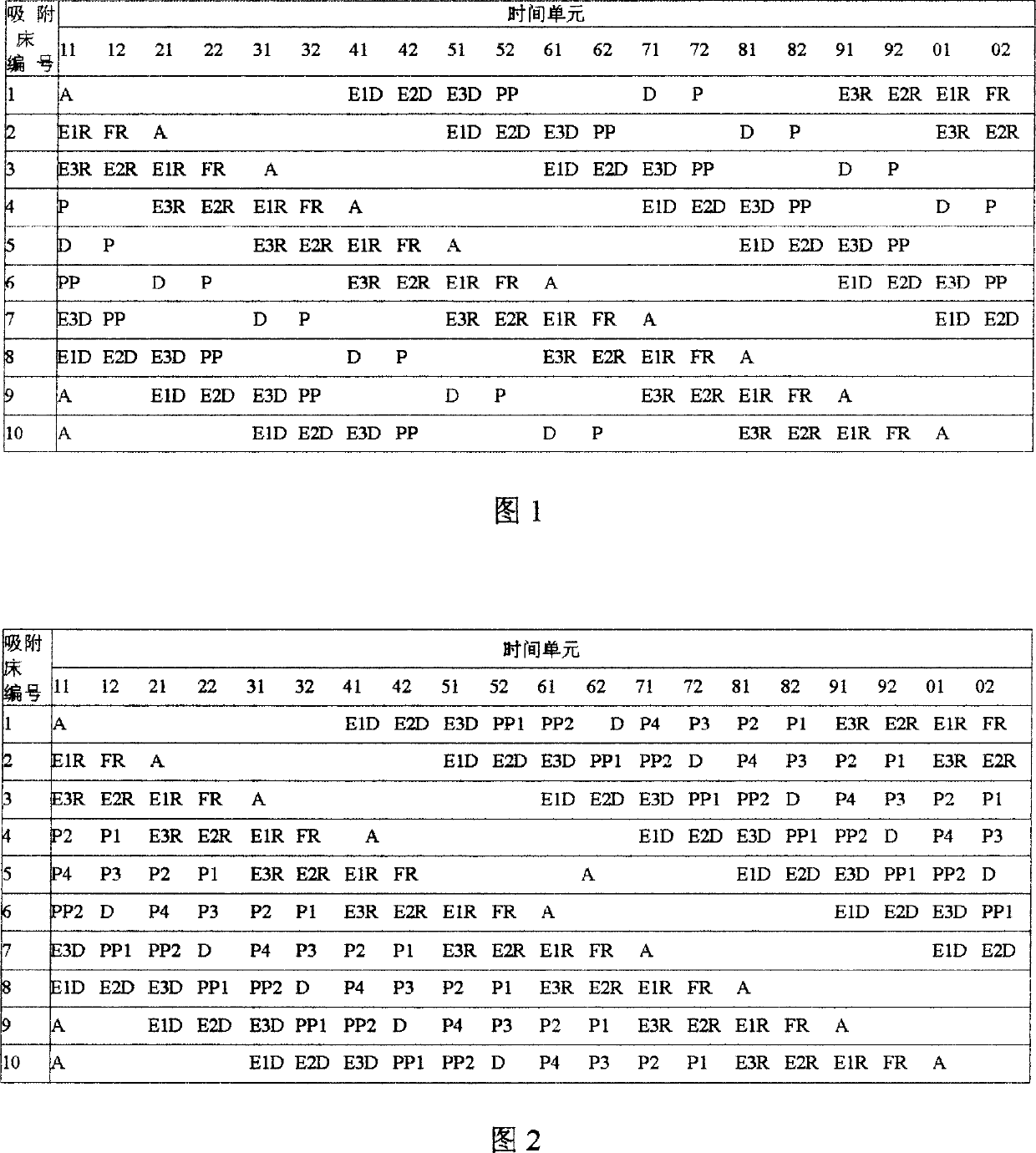

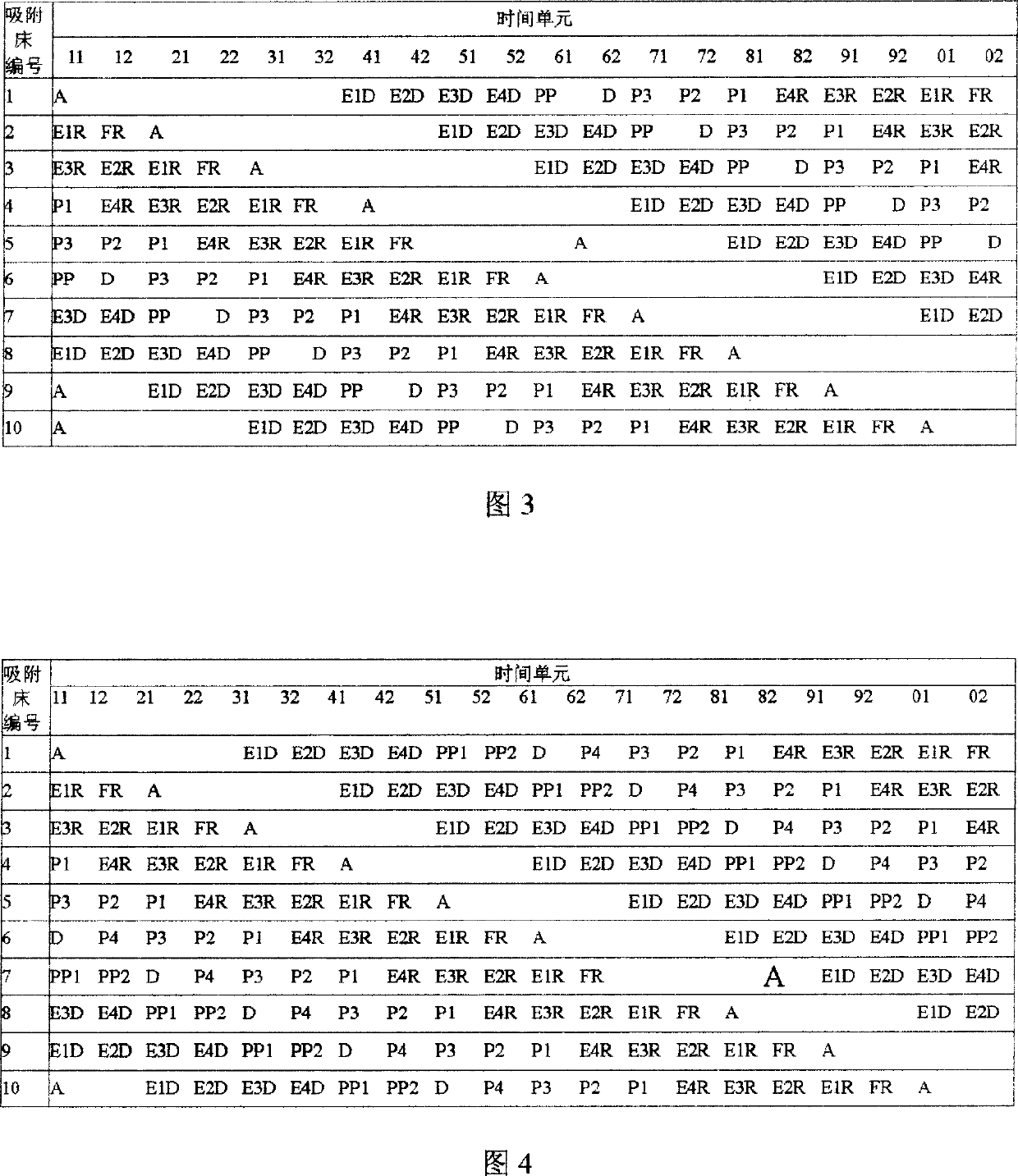

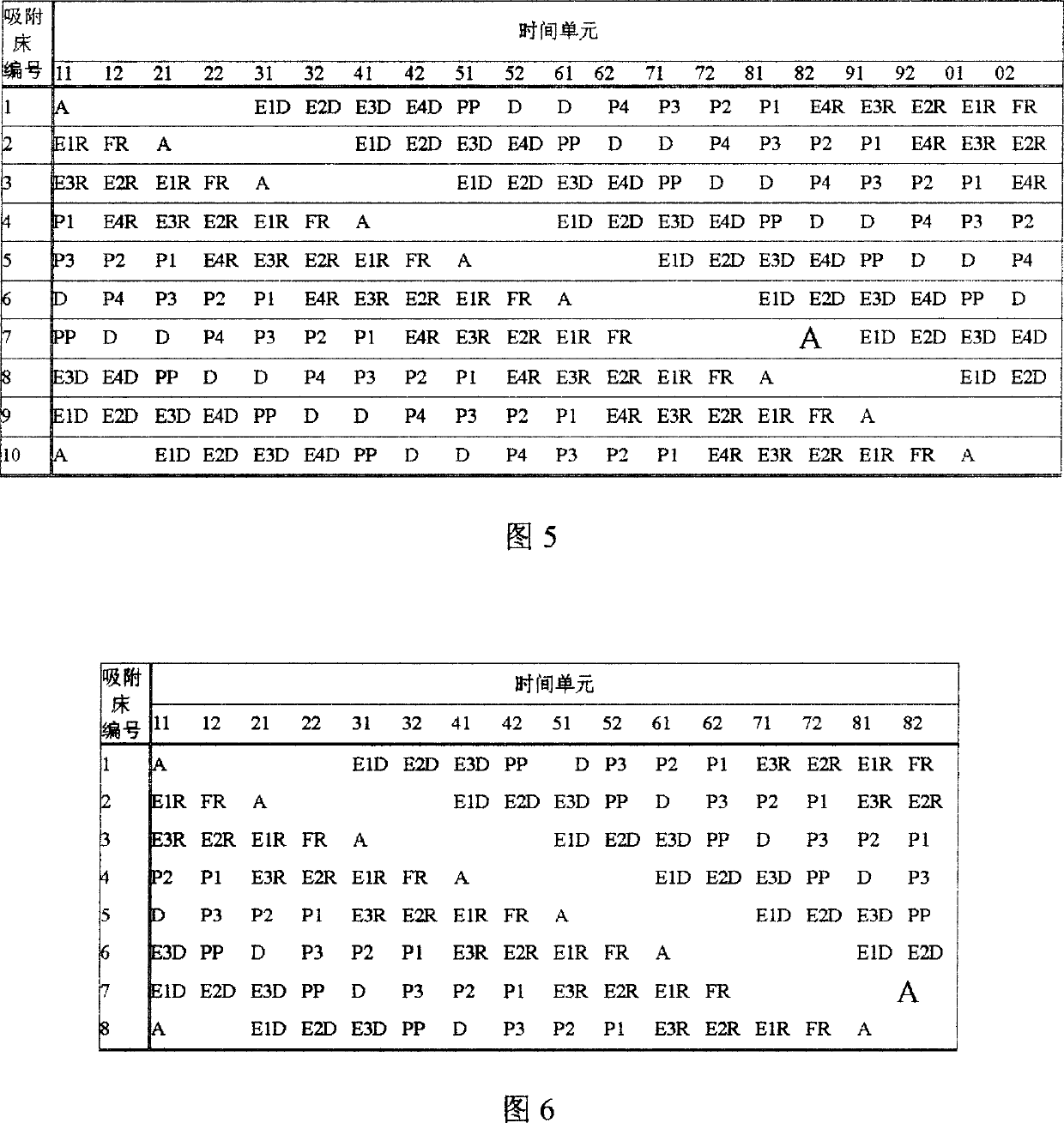

[0077] In this example, for a hydrogen production capacity of 50000Nm 3 / h Industrial hydrogen shift gas pressure swing adsorption hydrogen purification device, the adsorption pressure is 2.4Mpa, the adsorption temperature is normal temperature, and the desorption pressure is 0.03Mpa. The molar composition of the feed gas is: hydrogen, 70.2%, carbon monoxide, 3%, carbon dioxide, 21.3%, methane, 5.5%, water, saturated, and the purity of the product hydrogen is greater than 99.9%. The adsorbent that adopts is molecular sieve commonly used in industry, gac, silica gel, respectively adopts 10 bed pressure swing adsorption techniques (process 1) of the known technology described in Fig. 1 and 10 bed pressure swing adsorption of the present invention described in Fig. 2 Technology (process 2), 10-bed pressure swing adsorption process (process 3) of the present invention described in Fig. 4, 10-bed pressure swing adsorption process (process 2) and (process 3) of the present invention ...

example 2

[0080] In this example, for a hydrogen production capacity of 15000Nm 3 The shift gas pressure swing adsorption hydrogen purification device of / h industrial hydrogen, operating conditions, feed gas composition and adsorbent are all identical with example 1, respectively adopt the 10-bed pressure swing adsorption process (process 1) of known technology described in Fig. 1 And 6 bed pressure swing adsorption techniques (process 4) of the present invention described in Fig. 9, 7 bed pressure swing adsorption techniques (process 5) of the present invention described in Fig. 10, 6 bed pressure swing adsorption techniques (processes) of the present invention 4) and the 7-bed pressure swing adsorption process (process 5) did not use auxiliary pressure equalization, and their technical comparisons are shown in Table 2:

[0081] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption pressure | aaaaa | aaaaa |

| Adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com