Method for manufacturing recoverable, nontoxic, nonflammable acoustic insulating material and its structure

A technology of sound insulation materials and manufacturing methods, applied in the direction of sound insulation, insulation layer, building components, etc., can solve the problems of unstable shrinkage rate of product substrates, high product defect rate, poor sound absorption effect of materials, etc., to achieve elasticity and Polymerization ability, excellent sound insulation performance, and the effect of improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

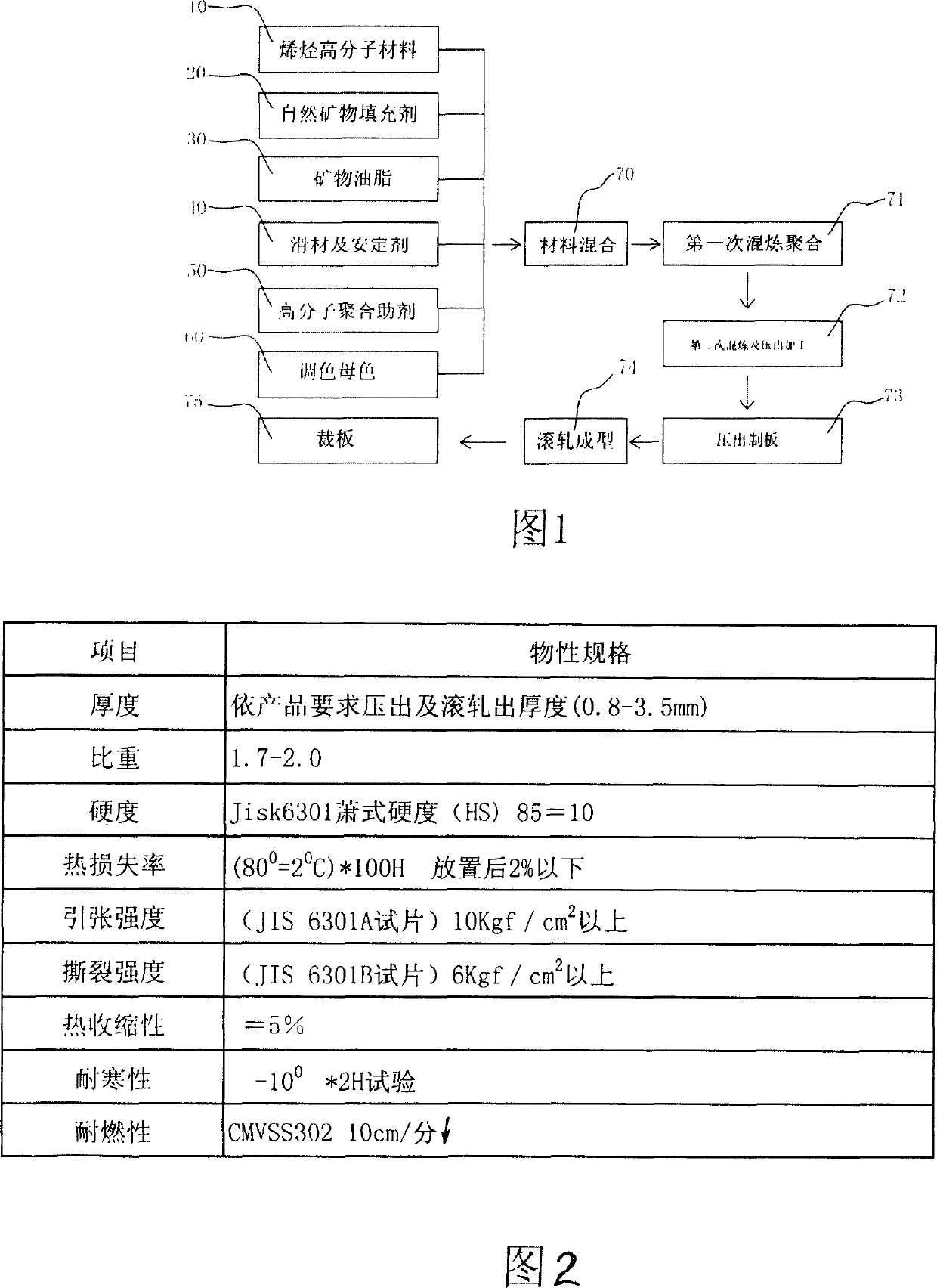

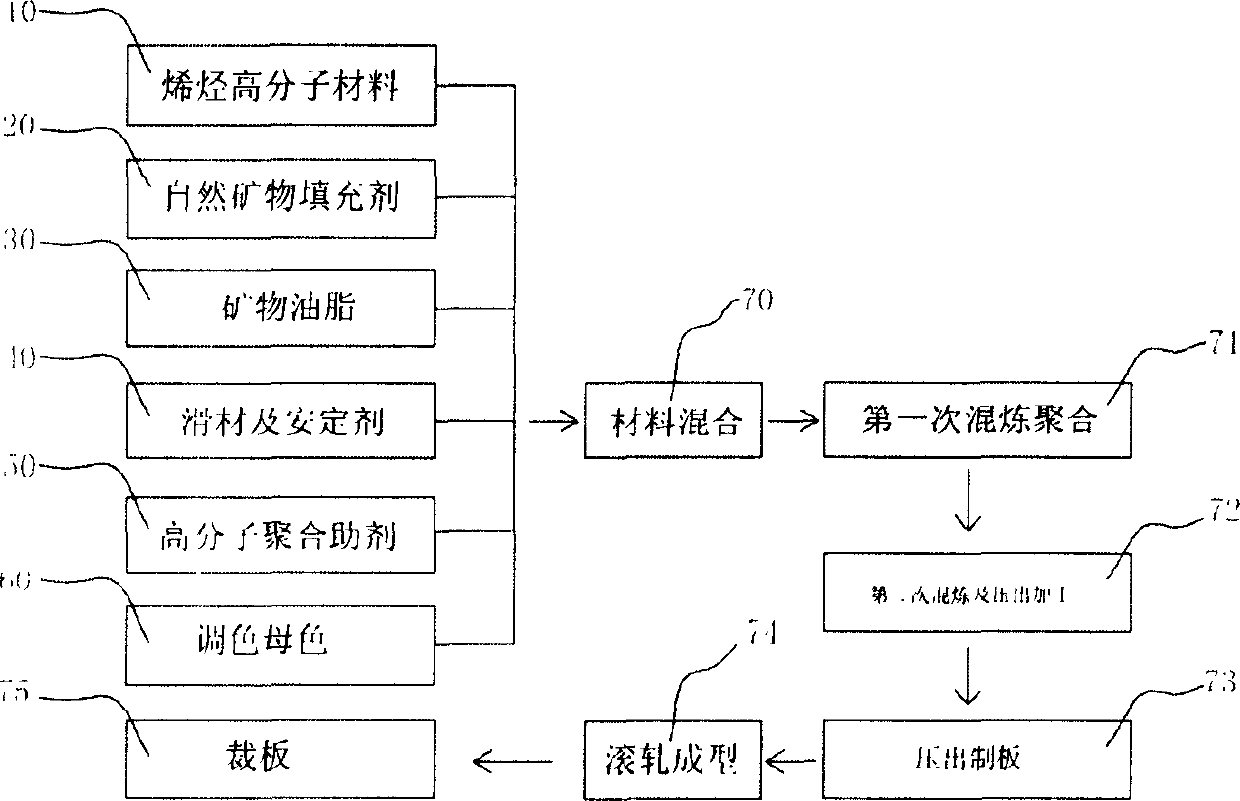

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Referring to Fig. 1, its raw material comprises:

[0027] 1. Olefin polymer material (10): It can be EVA and LLDPE, and its proportion can be added as needed. If it is used to manufacture automobile outer hub plates, its proportion accounts for about 10% of the total material.

[0028] 2. Natural mineral filler (20): Calcium carbonate CaCo can be used 2 , if it is used to manufacture automobile outer hub plates, its composition can account for 80% of the total raw materials.

[0029] 3. Mineral grease (30): It can be a kind of operating oil, especially DOP oil. If it is used to manufacture automobile outer hub plates, its proportion accounts for about 4% of the total raw materials.

[0030] 4. Sliding material and stabilizer (40): It is a kind of hard acid zinc, if it is used for manufacturing automobile outer hub plates, its proportion is preferably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com