Process of extracting phosphatidylcholine from soybean phosphatide

A technology of phosphatidylcholine and soybean lecithin, which is applied in the directions of edible phospholipid composition, food science, protein food ingredients, etc., can solve the problems of product yield and product purity being difficult to take into account at the same time, and achieves less solvent consumption and extraction process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

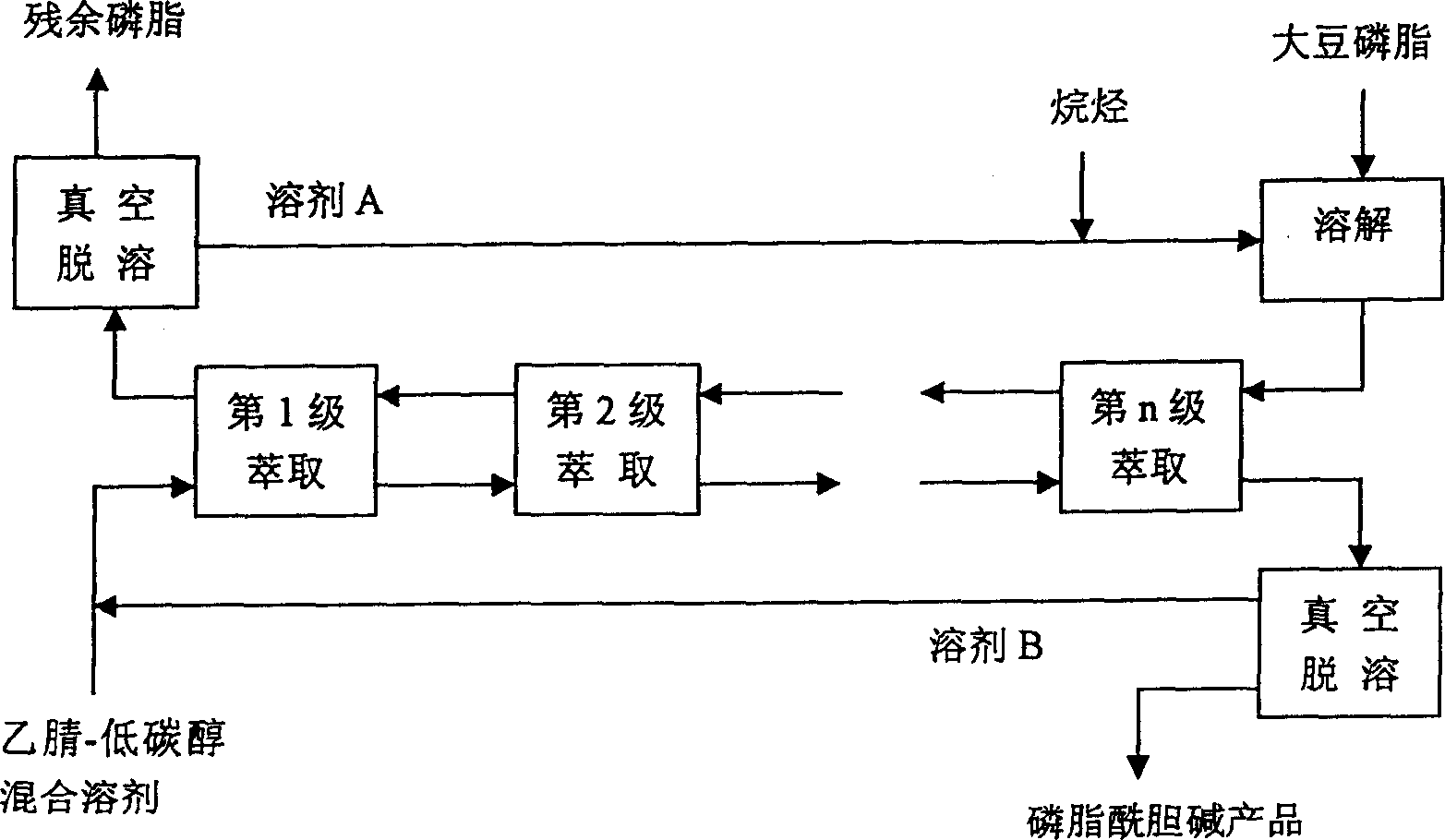

[0017] The powdered soybean lecithin containing 23% phosphatidylcholine is formulated into a 10% concentration of phospholipid n-hexane solution as a raw material solution, and an extractant of acetonitrile:ethanol=1:3 (volume ratio) is prepared. Adopt extraction agent: feedstock liquid=1: 2 (volume ratio) feed ratio, at 30 ℃, under the condition of 60 minutes of extraction time of each stage, according to figure 1 The scheme shown performs a 3-stage counter-current extraction. The obtained product is detected by high-performance liquid chromatography, and the content of phosphatidylcholine is 84.2%, and the yield is 93%.

Embodiment 2

[0019] A 20% concentration of phospholipid petroleum ether solution was formulated with powdered soybean lecithin containing 23% phosphatidylcholine as a raw material solution, and an extractant of acetonitrile:methanol=1:6 (volume ratio) was prepared. Adopt extraction agent: feedstock liquid=1: 1 (volume ratio) feed ratio, at 40 ℃, under the condition of 30 minutes of extraction time of each stage, press figure 1 The scheme shown performs a 5-stage counter-current extraction. The obtained product is detected by high-performance liquid chromatography, and the content of phosphatidylcholine is 88.8%, and the yield is 95%.

Embodiment 3

[0021] Containing 23% phosphatidylcholine powdered soybean lecithin to prepare a 15% concentration of phospholipid heptane solution as a raw material solution, and prepare an extractant of acetonitrile:n-propanol=5:1 (volume ratio). Adopt extraction agent: feedstock liquid=4: 1 (volume ratio) feed ratio, at 25 ℃, under the condition of 80 minutes of extraction time of each stage, press figure 1 The scheme shown performs a 6-stage counter-current extraction. The obtained product is detected by high-performance liquid chromatography, and the content of phosphatidylcholine is 93.5%, and the yield is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com