Process for extracting rubusoside of fruit of Gorsvenor Momordica

A mogroside and extraction process technology, applied in the field of extracting sweet glycosides, can solve the problems of low product purity, large equipment investment and high product cost, and achieve the effects of high product purity, low capital and raw material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

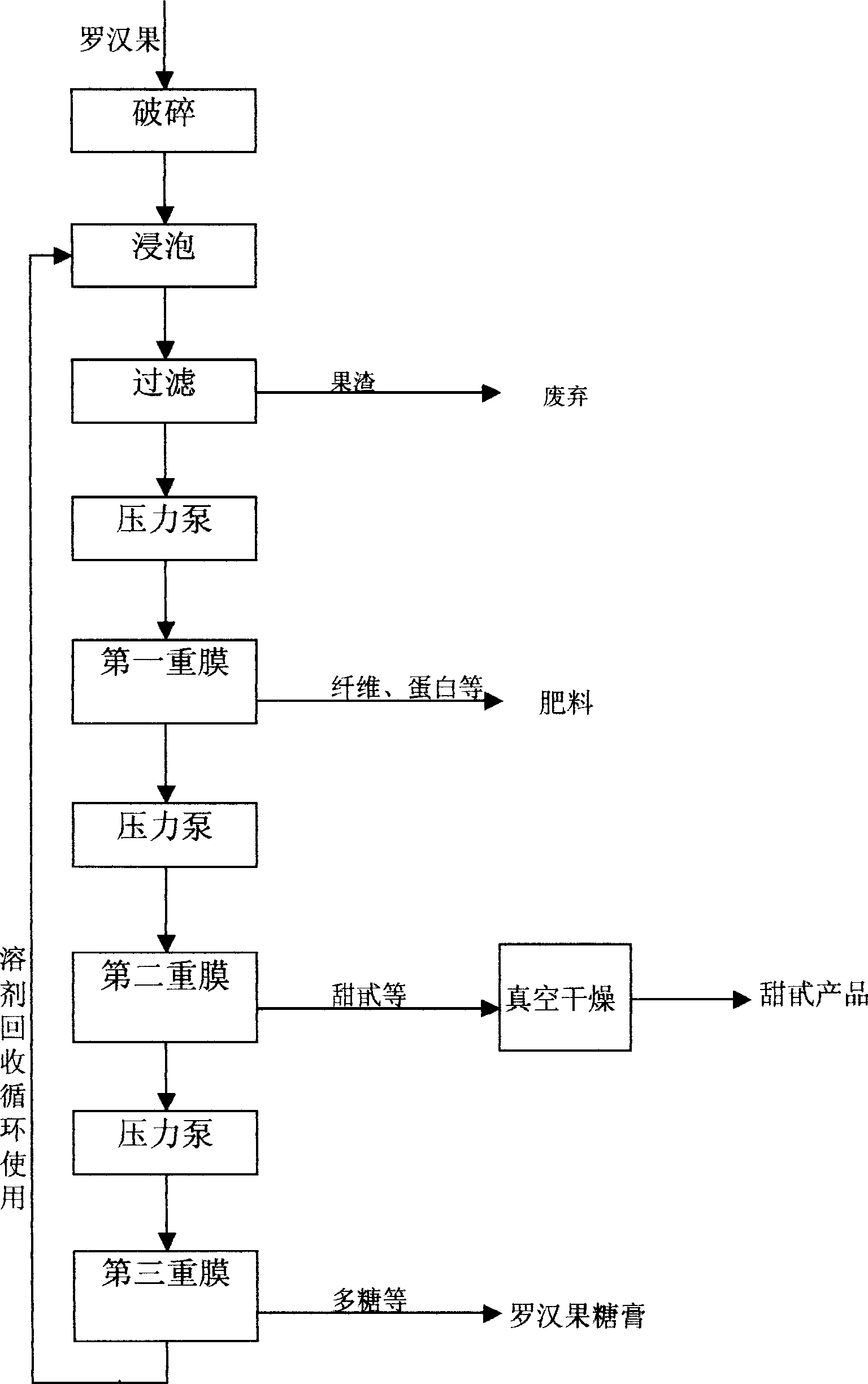

Image

Examples

Embodiment 1

[0025] Take 1 kg of fresh Luo Han Guo, break it into pieces of 1-2 cm, add 2 kg of 40% ethanol aqueous solution, heat to 50°C, keep the temperature at 40-50°C, and soak for 10 hours. Filtrate with a 200-mesh filter to obtain the Luo Han Guo extract, and the waste pomace can be used to make fertilizer, etc. The pH value of the leachate is 5. The leachate is cooled to 25-30°C, passed through the first-stage pressure pump, and passed through the first ultrafiltration membrane separation module under a working pressure of 0.01-0.03Mpa, and the concentrated Luo Han Guo fiber, protein, pectin, impurities and ash are intercepted and separated A total of 80 grams is sent out from the first outlet; the remaining filtrate passes through the second stage nanofiltration membrane separation module under the working pressure of 0.04-0.06Mpa through the second-stage pressure pump, and intercepts and separates the concentrated mogroside solution with a concentration of 28 degrees Baumé, sent...

Embodiment 2

[0027] Take 1 kg of dried Luo Han Guo, break it into 0.5-1.5 cm pieces, add 10 kg of 50% ethanol aqueous solution, heat to 60°C, keep the temperature at 40-60°C, and soak for 15 hours. Filter with a 250-mesh filter to obtain the Luo Han Guo extract, and the waste pomace can be used for fertilizer production. The pH value of the leachate is 6. The leachate is cooled to 25-30°C, passed through the first-stage pressure pump, and passed through the first ultrafiltration membrane separation module at a working pressure of 0.02-0.05Mpa, and the concentrated Luo Han Guo fiber, protein, pectin, impurities and ash are intercepted and separated A total of 30 grams is sent from the first discharge port; the remaining filtrate is passed through the second stage of the pressure pump at a working pressure of 0.05-0.08Mpa through the second nanofiltration membrane separation module, and the concentrated mogroside solution is intercepted and separated, with a concentration of 26 degrees Baum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com