Comprehensive control method for heating furnace outlet temperature and device thereof

A technology of comprehensive control of outlet temperature, applied in the field of comprehensive control method and device, comprehensive control method and device of heating furnace outlet temperature, capable of solving problems such as deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

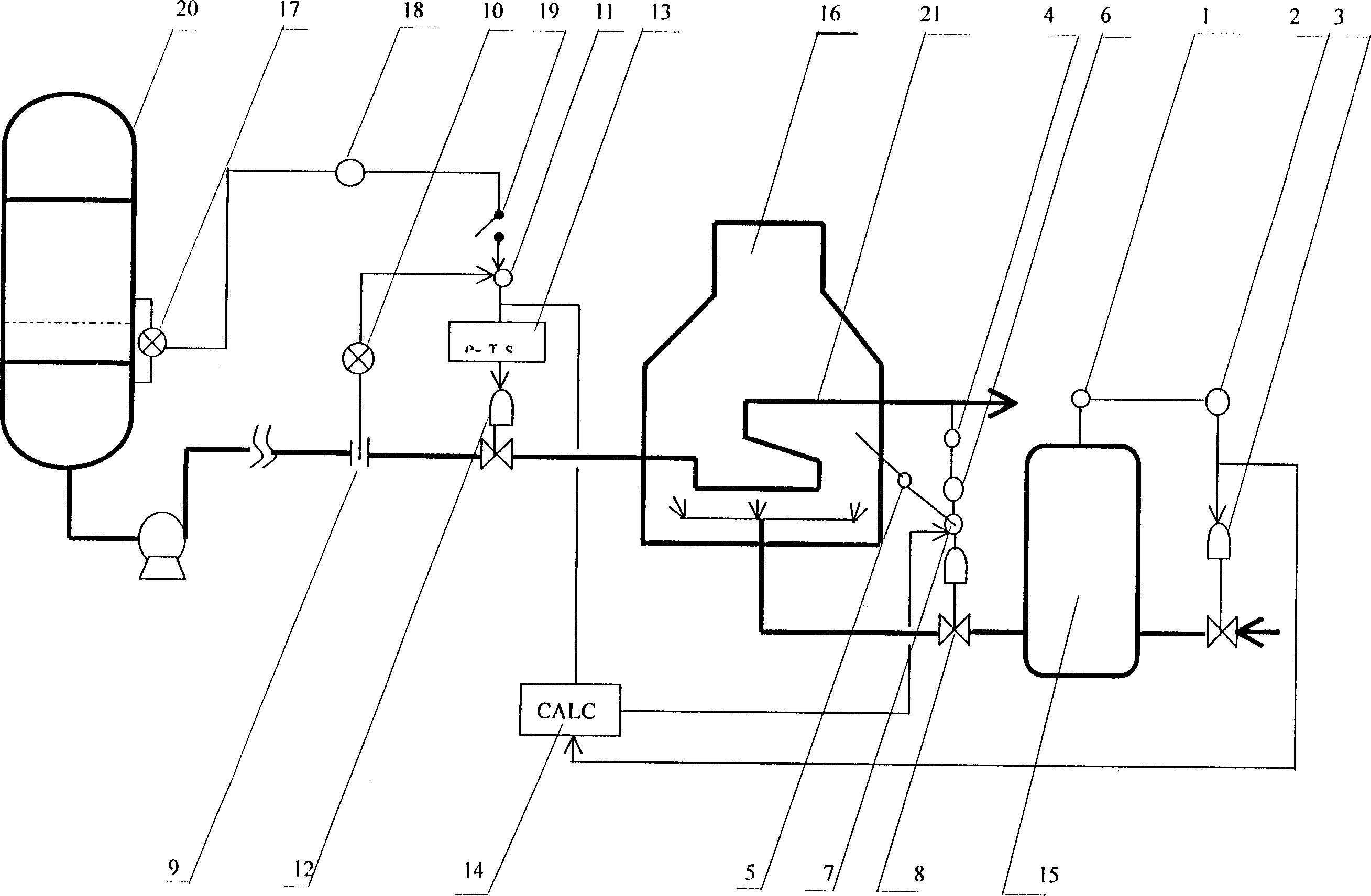

[0058] Hereinafter, the present invention will be described in detail by taking the comprehensive control system adopted by the waste liquid heating furnace of the furfural refining device in the petroleum processing plant as an example.

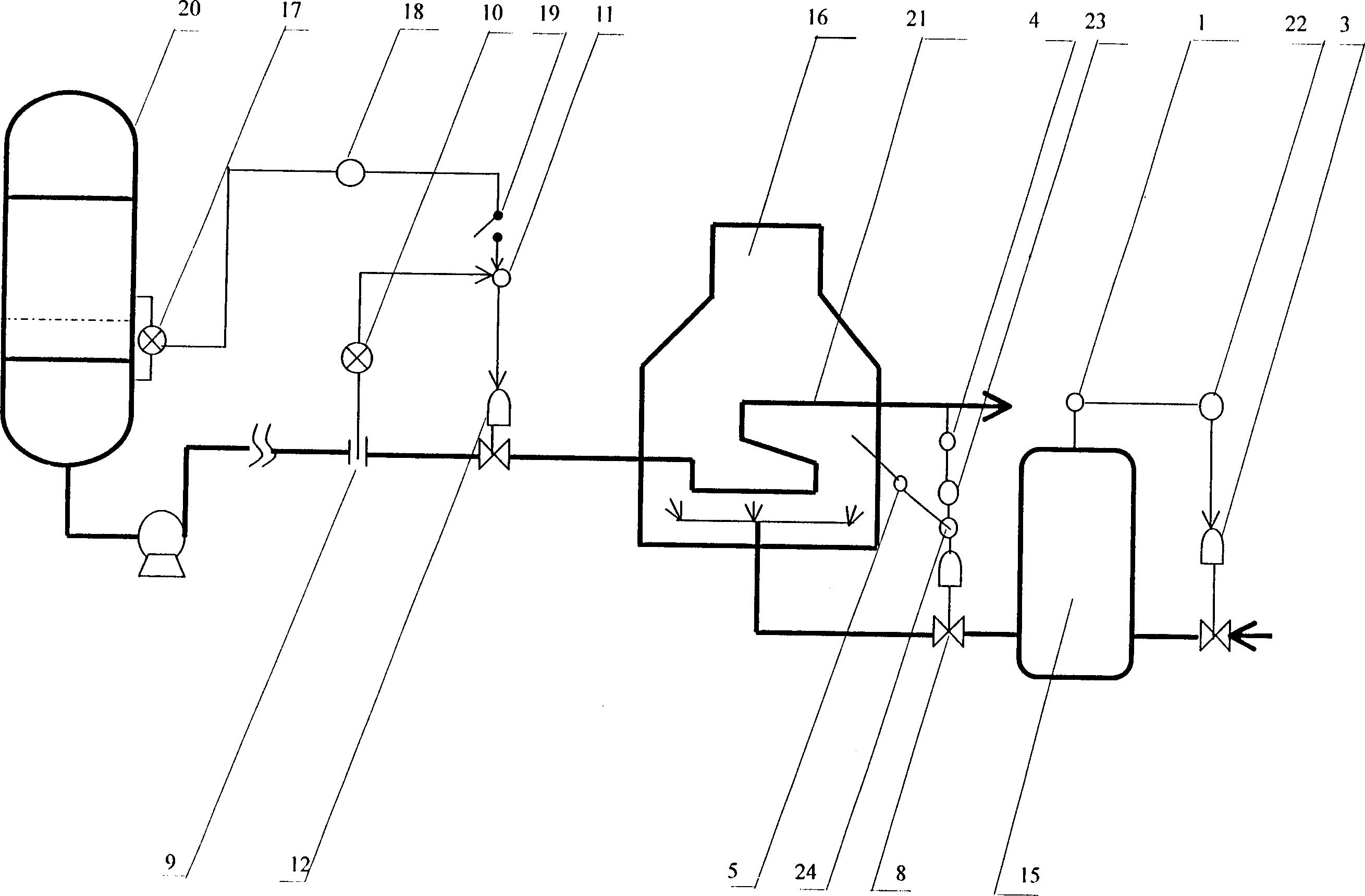

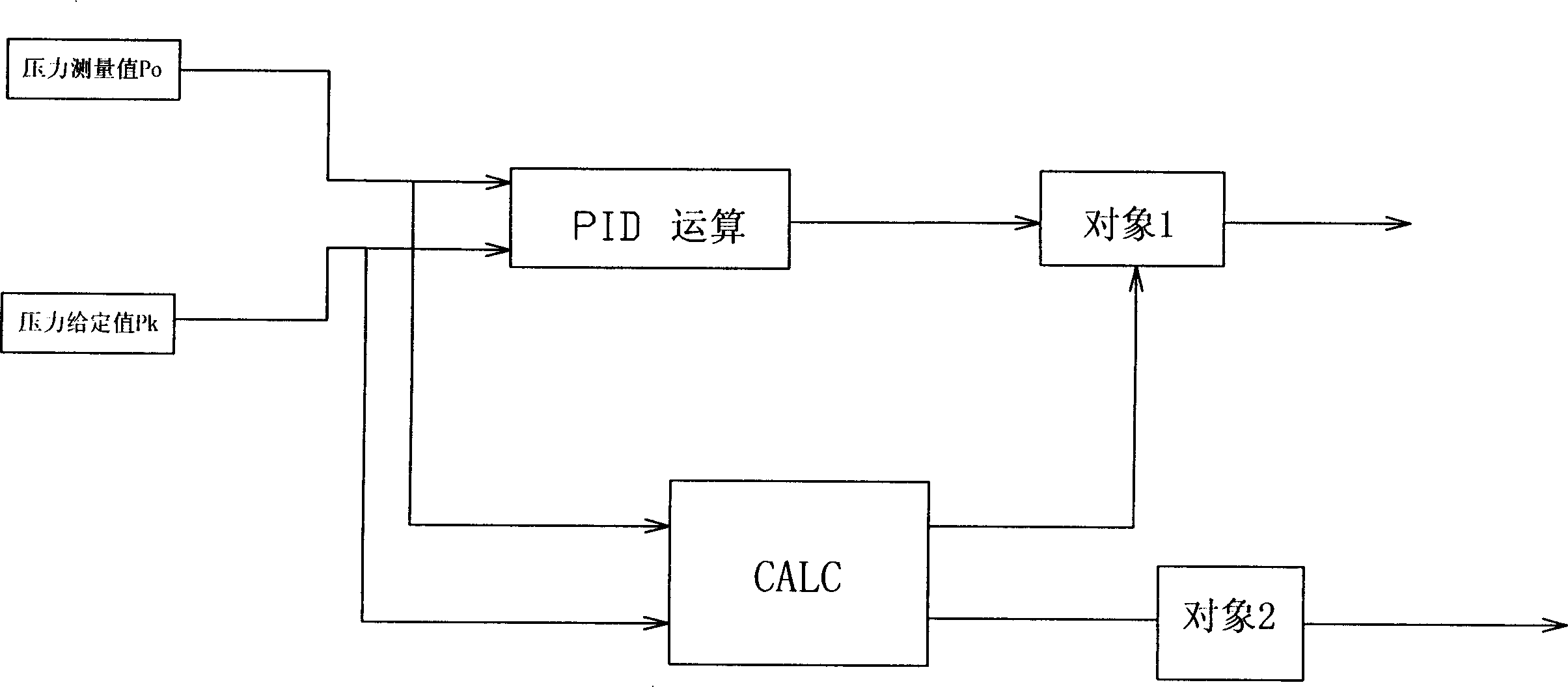

[0059] Such as figure 2 As shown, the comprehensive control system for the outlet temperature of the heating furnace includes: furnace tube 21, furnace feed quantity control system I, furnace and furnace outlet temperature control system II and fuel oil and / or gas pressure control system III, The output signal of the furnace feed rate control system is transmitted to the furnace and furnace outlet temperature control system, and the output signal of the fuel oil and / or gas pressure control system is transmitted to the furnace and furnace outlet control system, wherein,

[0060] Furnace feed amount control system 1 comprises: furnace feed amount orifice plate 9, feed amount flow transmitter 10, tower liquid level transmitter 17, liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com