Pulse preionization high-frequency discharging panel gas laser

A gas laser and high-frequency discharge technology, which is applied in the field of lasers, can solve the problems of low discharge energy density and achieve the effects of good discharge stability, wide application prospects, and high repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

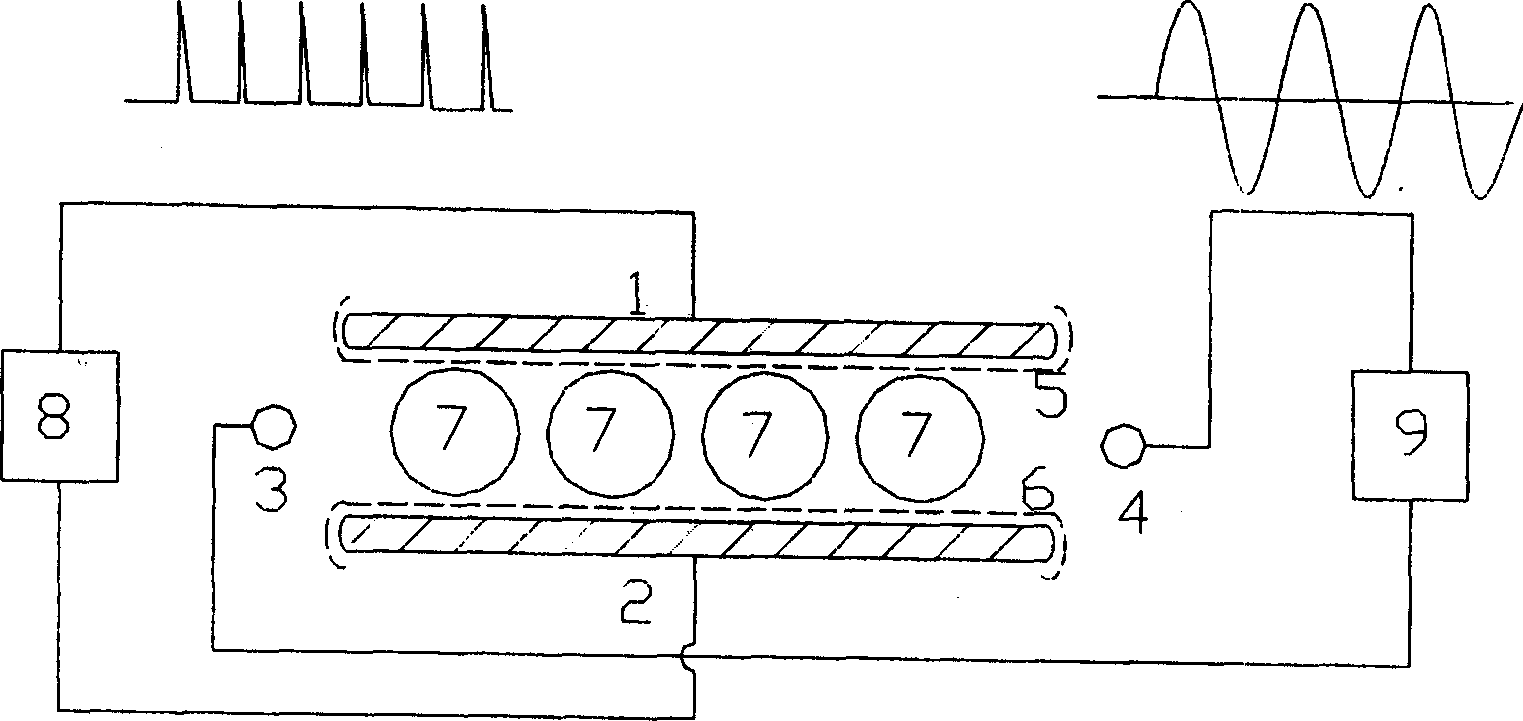

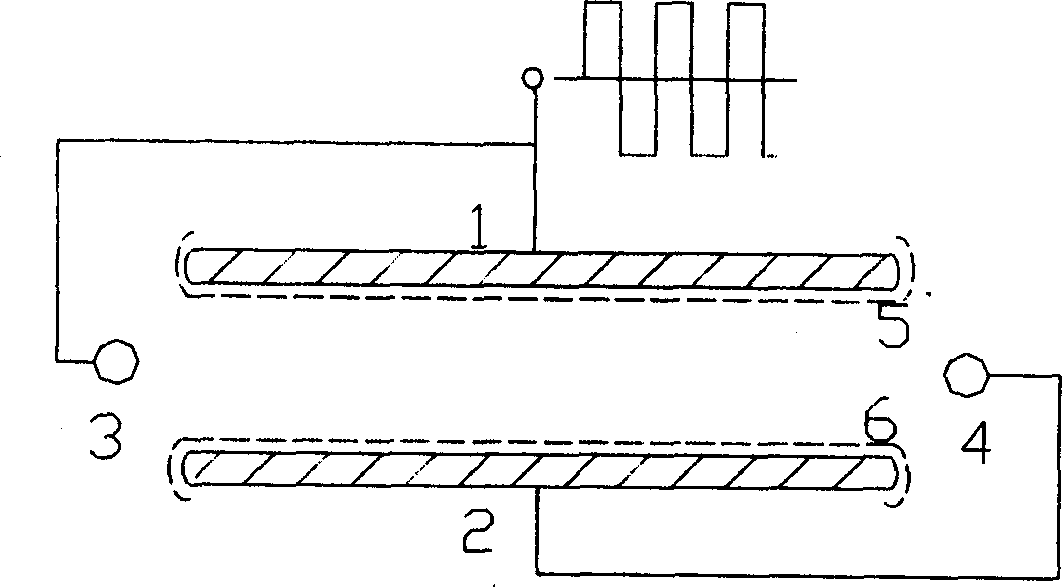

[0018] figure 2 It is the first embodiment of the present invention, wherein the main discharge electrode 3 is electrically connected to the pre-ionization electrode 1 , and the main discharge electrode 4 is electrically connected to the pre-ionization electrode 2 . A high-frequency square wave switching power supply is used as the main discharge power supply and also as a pre-ionization power supply, and its frequency is between 1kHz and 1MHz. The steep rising and falling edges of the square wave voltage applied to the electrodes contain higher frequency components, which easily enter the discharge area through the pre-ionization dielectric layers 5 and 6, forming a pre-ionization discharge before the main discharge. Because only one high-frequency square wave switching power supply is used, the whole system is more compact.

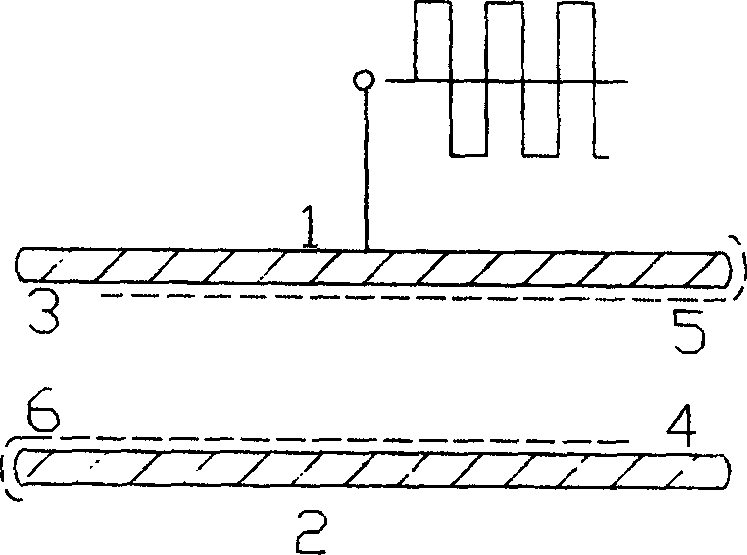

[0019] image 3 is the second embodiment of the present invention, is figure 2 further simplification and improvement. Wherein, the main discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com