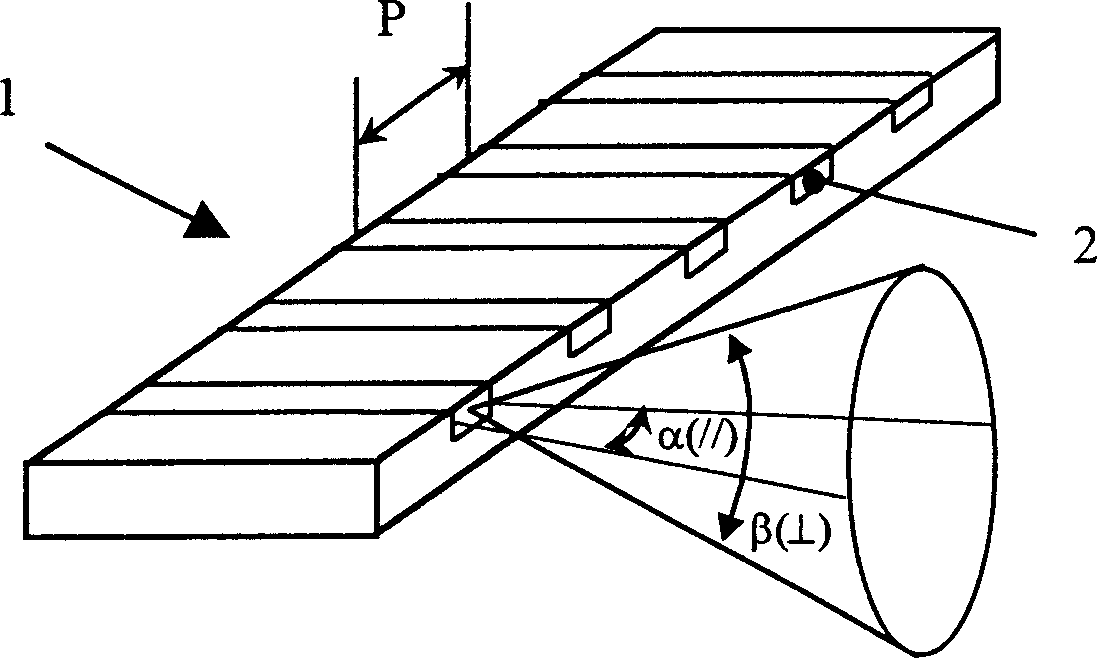

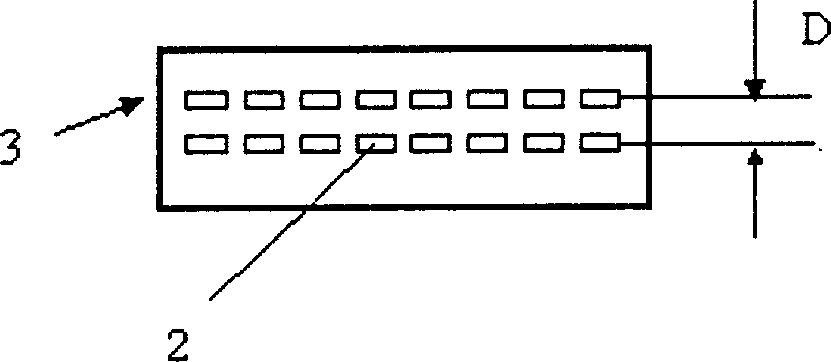

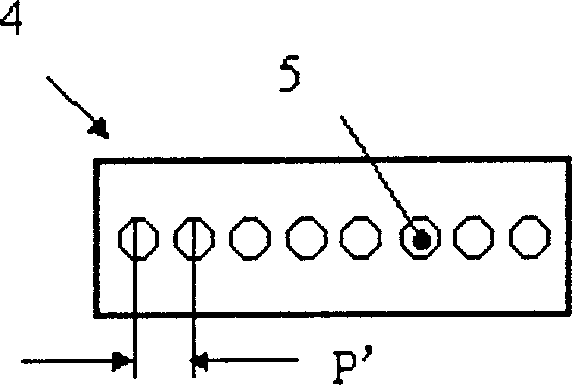

Coupling method for laminated semiconductor laser array and optical fiber array

A technology of laser array and fiber array, which is applied to semiconductor laser devices, coupling of optical waveguides, laser devices, etc., can solve problems such as impracticality, and achieve the effects of simple structure, good stability and small beam radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Figure 4 It is a schematic diagram of Embodiment 1 of the polarization beam combining technology of the present invention. Stacked semiconductor laser array 3 is arranged by two one-dimensional semiconductor laser arrays 6 and 7 (shown as the fast axis direction in the figure); The emitted light beam is collimated, and the collimated light beam passes through the total reflection mirror 13 to change the transmission direction of the light beam by 90°, and then reflects it by 90° by the polarization beam combining film 14, and the light beam from the one-dimensional semiconductor laser array 7 The collimated light beams are synthesized into light beams 15; the cylindrical lens 9 and the cylindrical lens array 11 are used to collimate the light beams emitted from the one-dimensional semiconductor laser array 7, and the collimated light beams are first passed through the half-wave plate 12 to rotate the polarization direction 90°, then pass through the polarization beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com