Semiconductor device

A semiconductor and device technology, applied in the field of electrical short-circuited semiconductor devices, to achieve the effect of preventing electrical short-circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method of manufacturing a semiconductor device according to Embodiment 1 of the present invention and a semiconductor device manufactured by the method will now be described.

[0030] First, processing to be performed in the state of the wafer for forming predetermined elements, wiring, and the like on the wafer is completed. At this time, in the dicing line region of the wafer, the conductive film for forming wiring and the like remains without being removed.

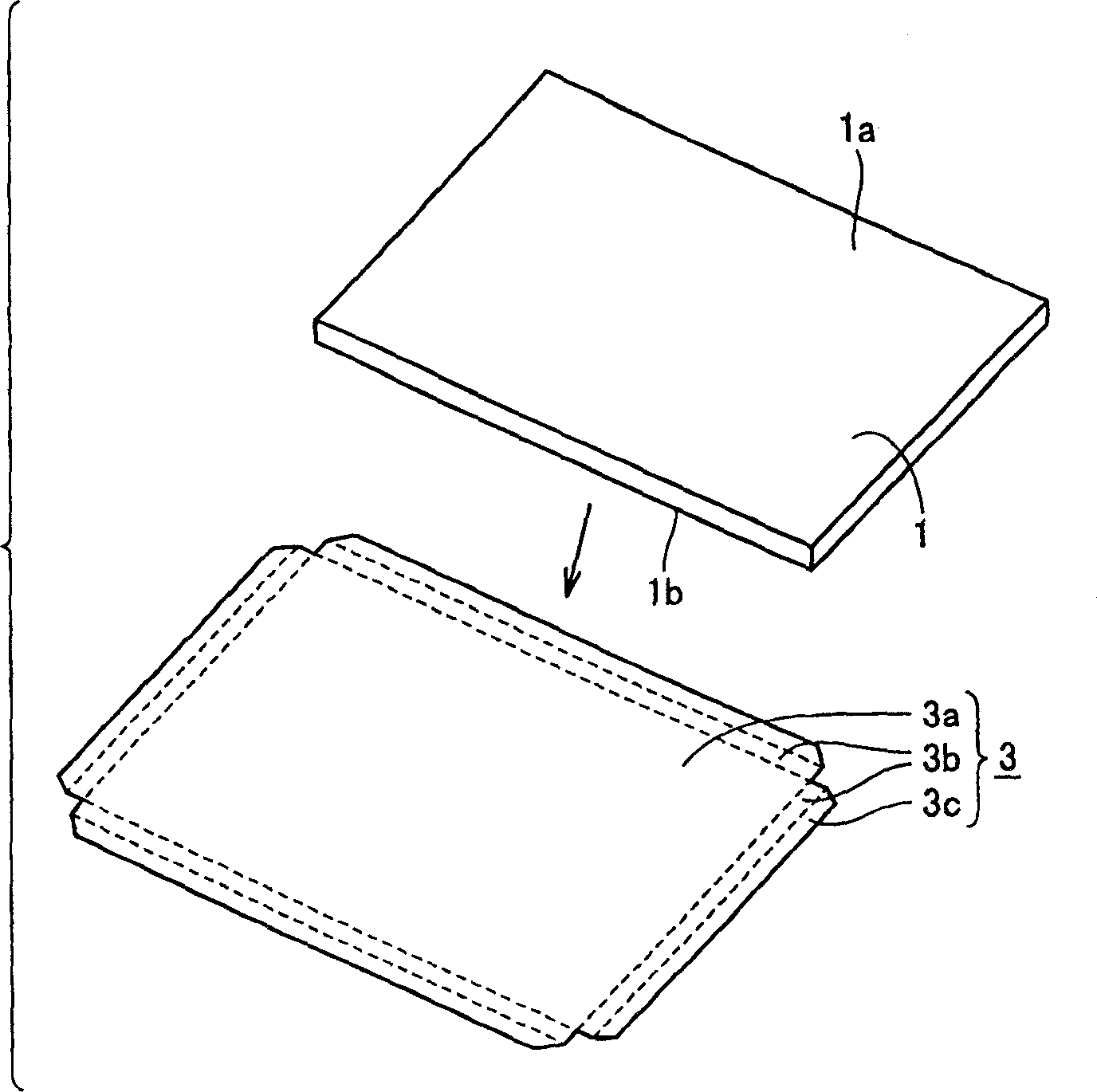

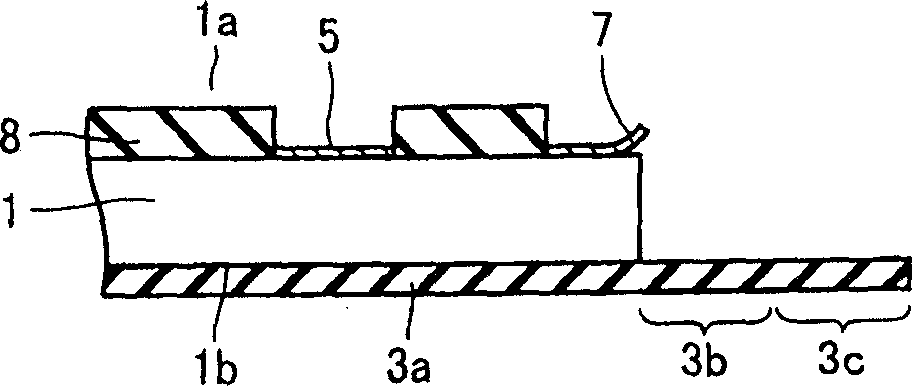

[0031] By dicing the wafer, such as figure 1 As shown, the semiconductor chip 1 is cut out. Such as figure 2 As shown, the surface 1a of the semiconductor chip 1 is covered with the passivation film 8, and the electrode portion 5, which is a so-called bonding pad, is exposed at the portion where the bonding wire is connected.

[0032] In addition, in the peripheral portion of the semiconductor chip 1 , there is a portion (burr) 7 rolled up by dicing in the conductive film remaining in the region of the dic...

Embodiment 2

[0045] A method of manufacturing a semiconductor device according to Embodiment 2 of the present invention and a semiconductor device manufactured by this method will now be described.

[0046] First, if Figure 8 As shown, in the same manner as the above-mentioned manufacturing method, dicing is performed in the dicing line region of the wafer without removing the conductive film for forming wiring and the like, leaving the semiconductor chip 1 out.

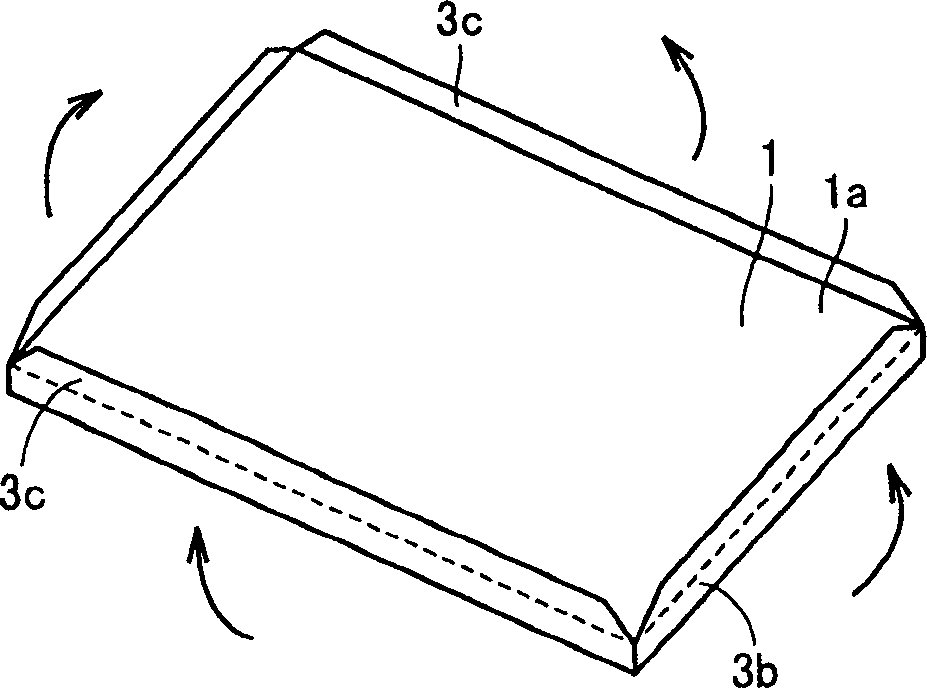

[0047] Then, if Figure 8 As shown, the insulating sheet member 3 attached to the semiconductor chip 1 is prepared so as to cover a predetermined portion of the semiconductor chip 1 . As the material of the insulating sheet member 3, a resin sheet member or a rubber sheet member can be used, and as will be described later, it is preferable to melt it by soldering heat in wire bonding.

[0048] At this time, the insulating sheet member 3 is provided with a first sticking portion 3a sticking to the surface 1a of the semiconducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com