Electronic device manufacturing method

A technology of electronic devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wiring patterns cannot be normally resolved, resist poisoning, etc., to expand the range of structure selection, prevent Resist poisoning phenomenon, effect of reducing variation in film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

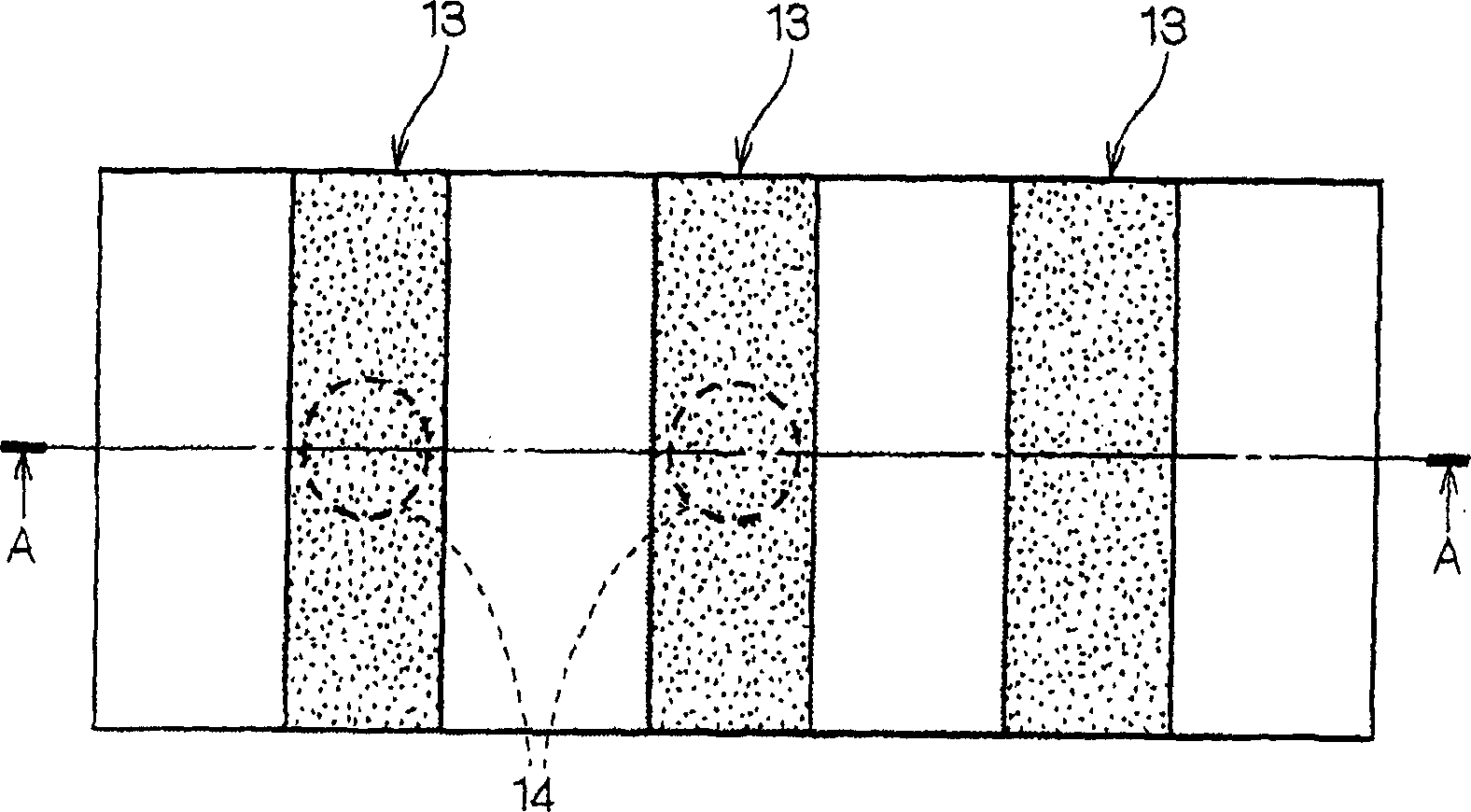

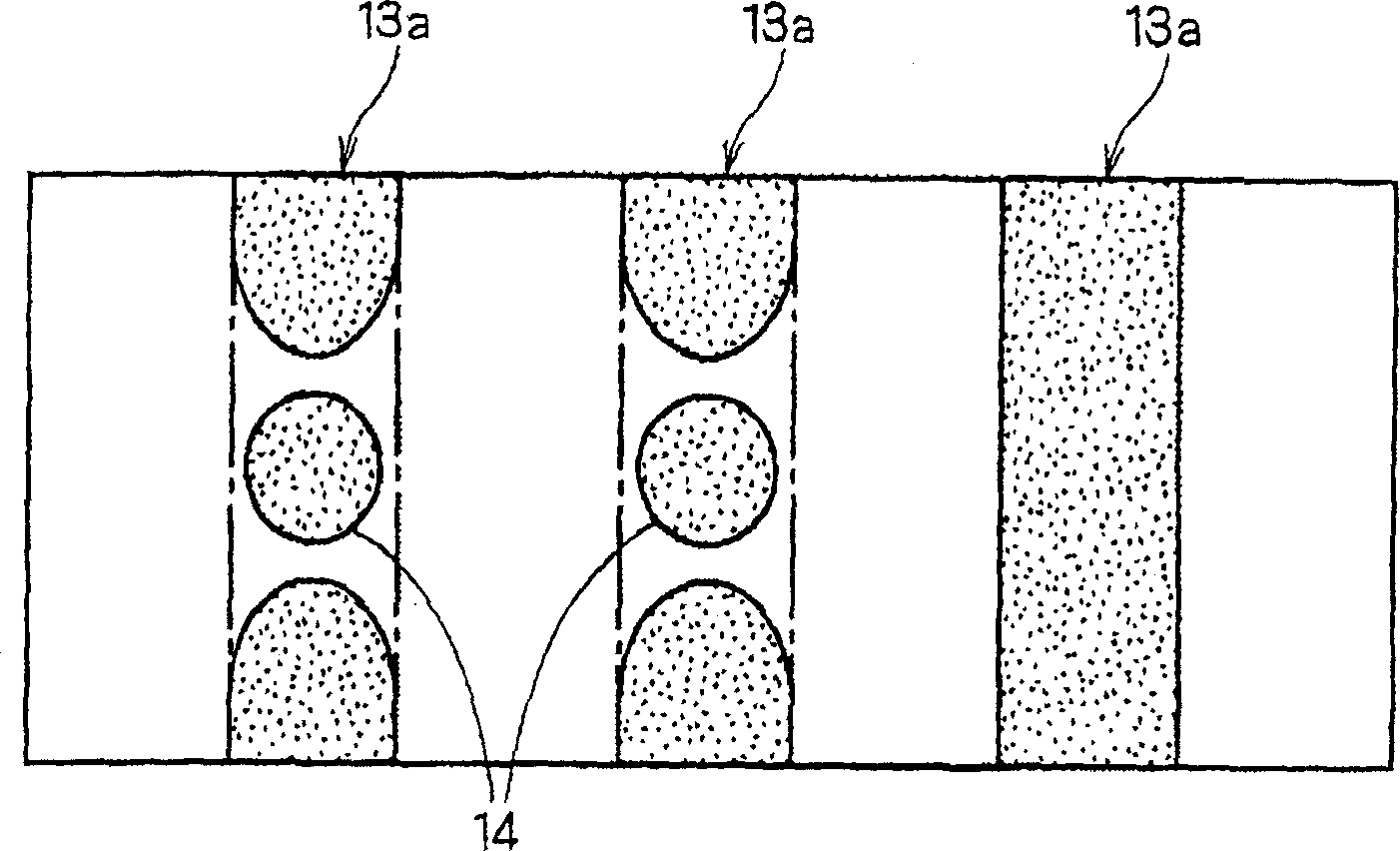

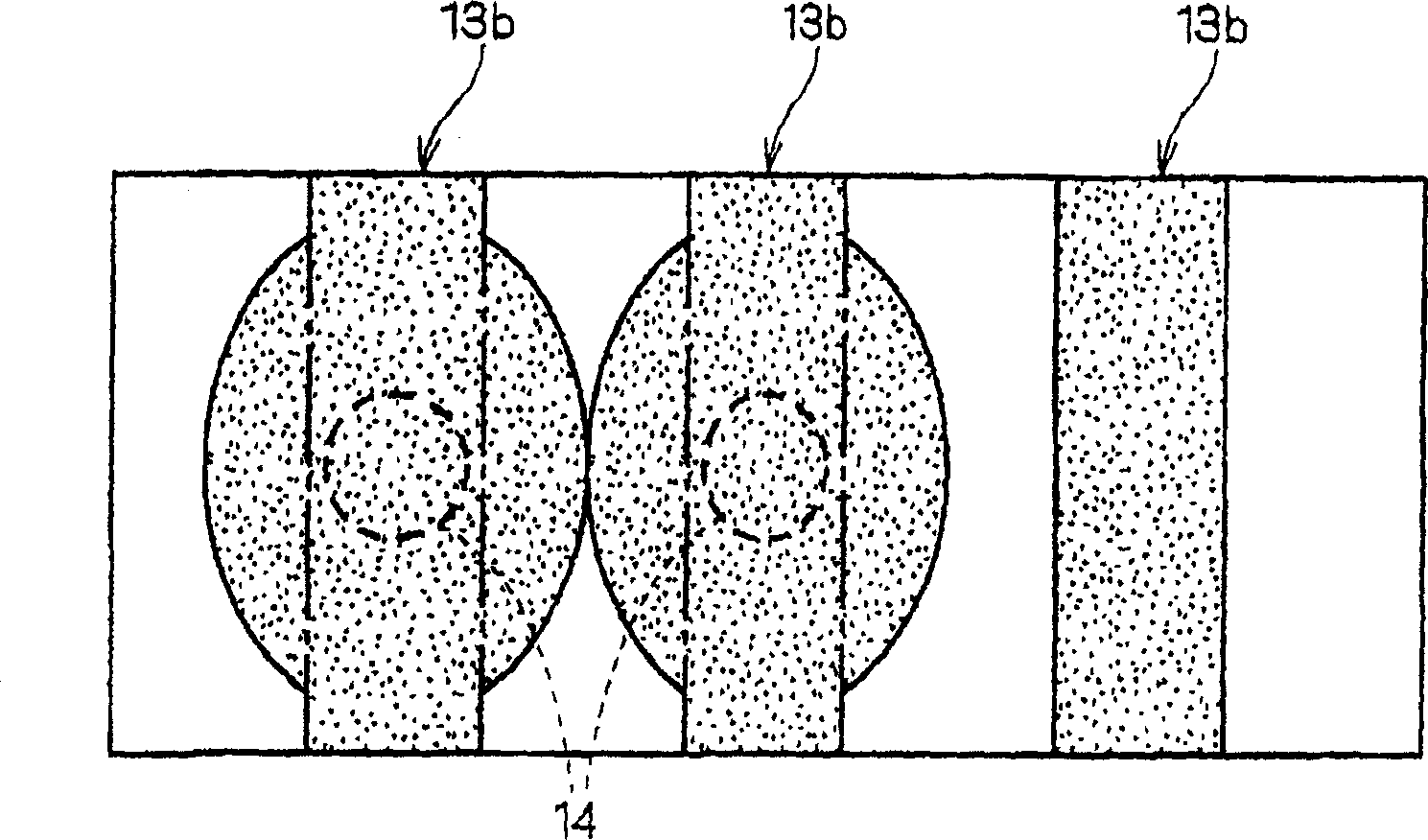

[0043]

[0044] Before describing the embodiment of the invention, the phenomenon of resist poisoning will be further explained.

[0045] In most cases, a semiconductor device having a buried multilayer wiring structure has an etching stopper film between an interlayer insulating film and an underlying structure, and an upper layer on the interlayer insulating film. protective film. At the same time, in order to suppress the increase in parasitic capacitance accompanying the adoption of a multilayer structure and enable high-speed operation, as an interlayer insulating film, carbon is introduced into silicon oxide in most cases, and the density is lower than that of general silicon oxide. , A low dielectric constant interlayer insulating film with a low dielectric constant.

[0046] In such a structure, when the upper protective film is formed, on the interface between the upper protective film and the low-permittivity interlayer insulating film, the surface decomposition a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com