Fully-automatic middle-water deep purifying and regenerating water reuse apparatus and process

A technology for deep purification and reclaimed water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. It can solve the problems of poor anti-pollution performance, easy biodegradation, and low purification efficiency. Achieve the effect of prolonging service life, reducing comprehensive cost and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

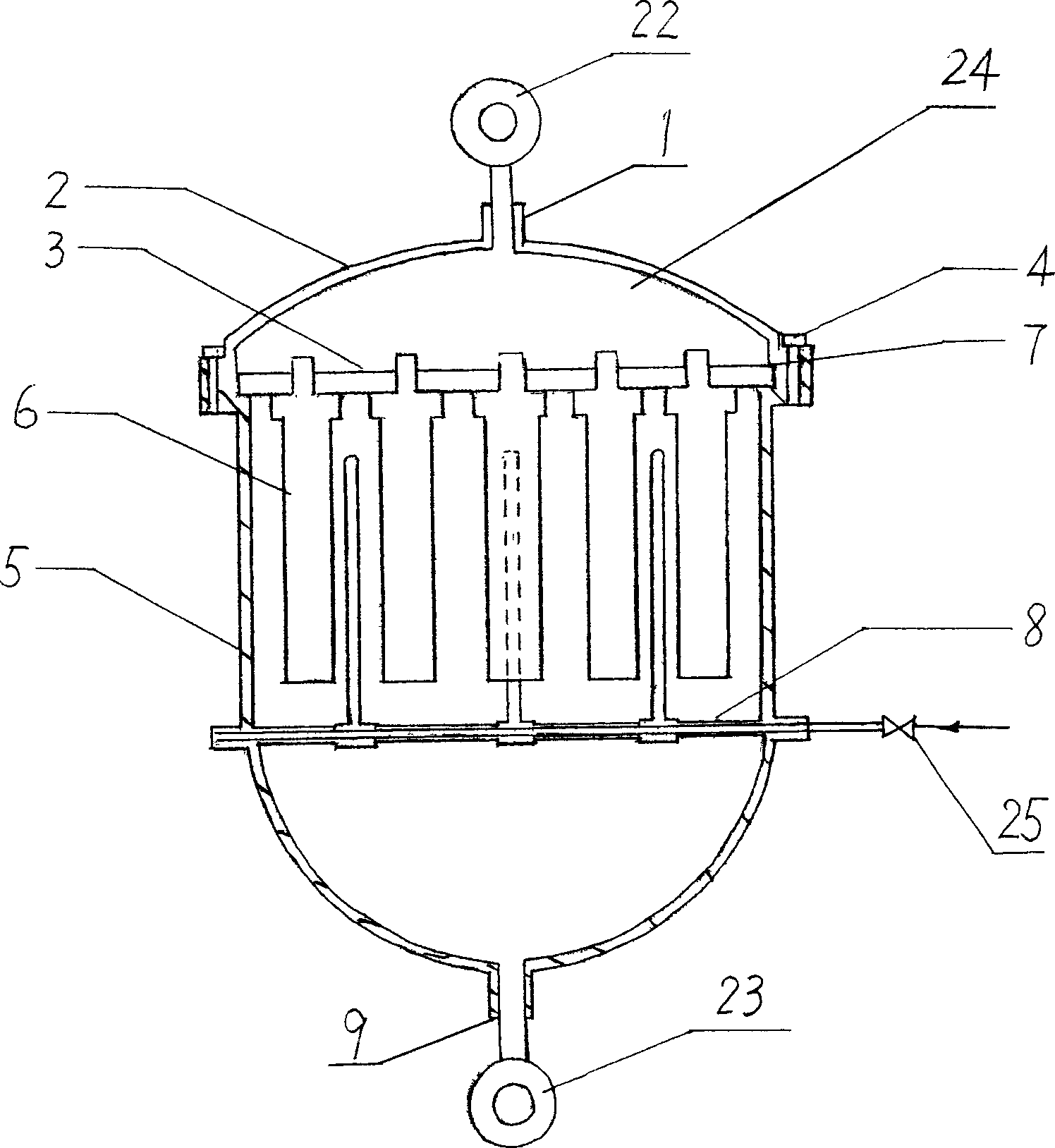

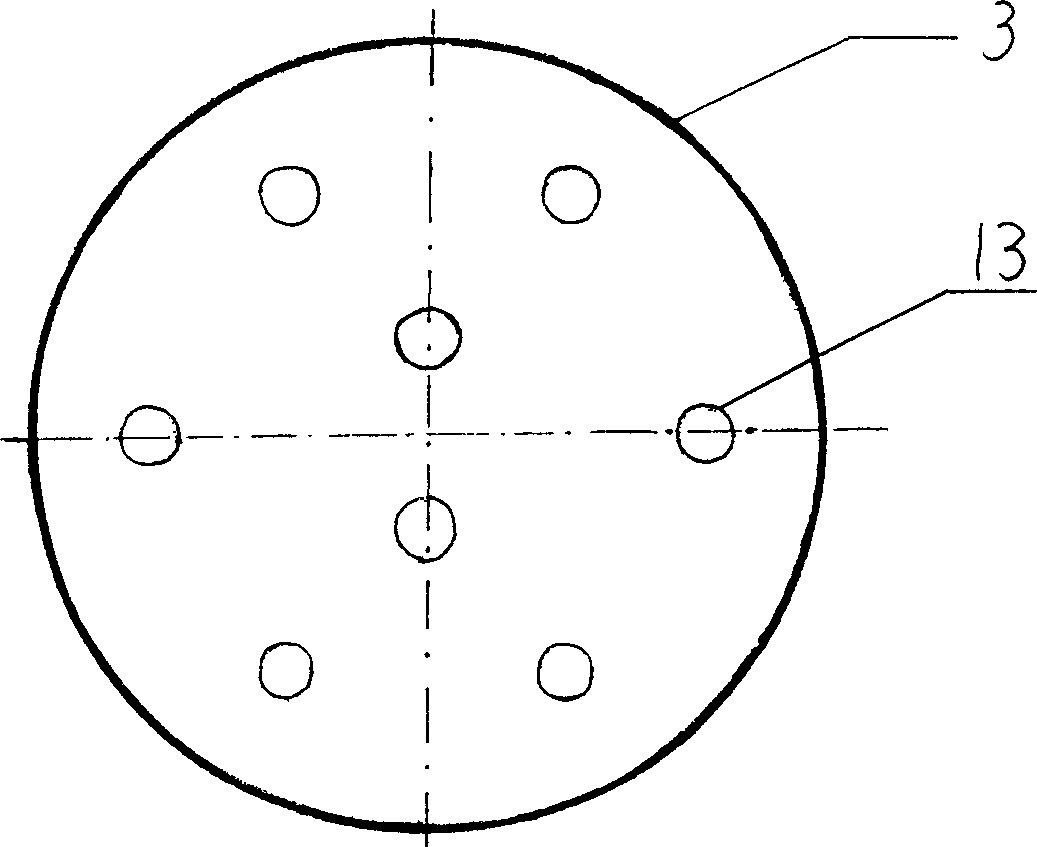

[0034] Such as figure 1 As shown, the shell of the positive pressure hollow membrane biochemical reactor is a tank body 5 with a top cover, the top of the top cover 2 has a water outlet 1, and the bottom of the tank body has a concentrated water outlet 9, and the top cover and the tank body are fixed. There are disk 3 (such as figure 2 Shown), the clean water chamber 24 is formed between the top of the disc and the loam cake; it is flange connection between the loam cake and the tank body, and a sealing ring 7 is placed in the middle to be connected by fastening bolts 4. The water outlet 1 on the top of the upper cover is connected to the timer switch valve 22 , and the concentrated water outlet 9 at the bottom of the tank is connected to the pressure sensing valve 23 .

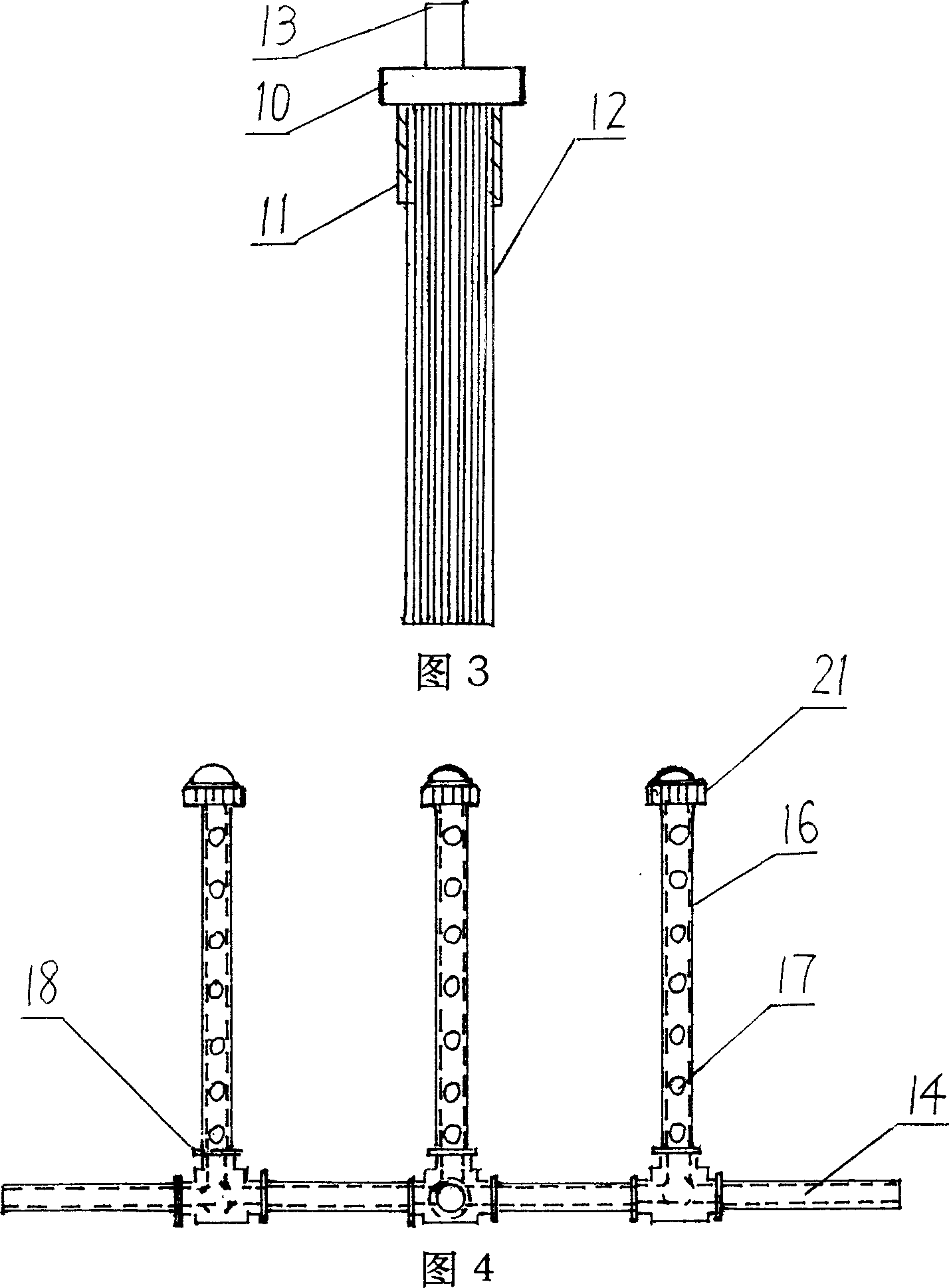

[0035] As shown in Figure 3, the upper part of each bundle of hollow ultrafiltration membranes 12 is placed in the module casing 11 and the module upper cover 10, and the inner core outlet 13 of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com