Novel method for producing and packing capillary chromatographic column sieve plate

A technology of capillary chromatographic column and capillary, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problems of difficult loading and unloading, increased experiment cost and difficulty, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

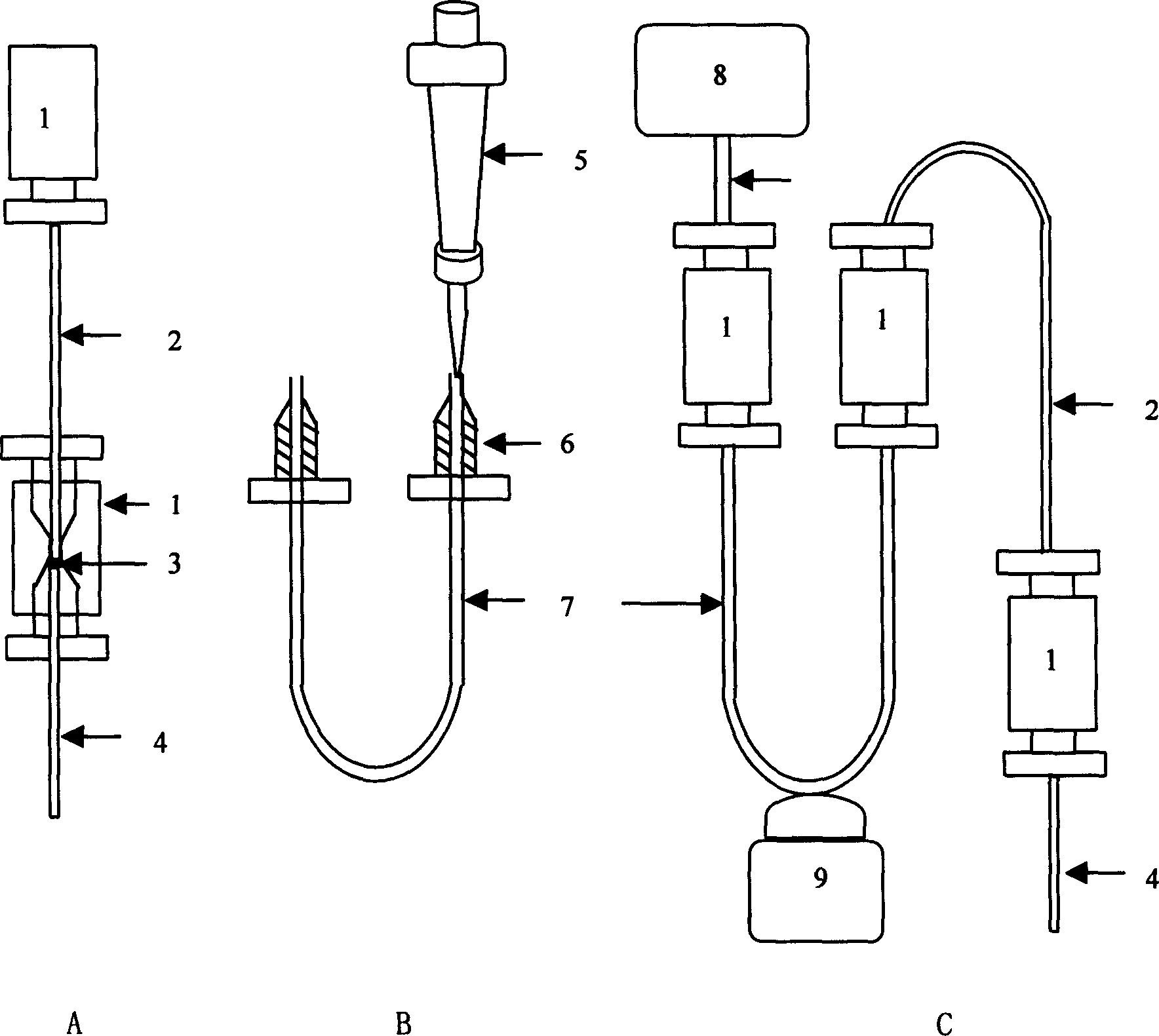

Method used

Image

Examples

Embodiment Construction

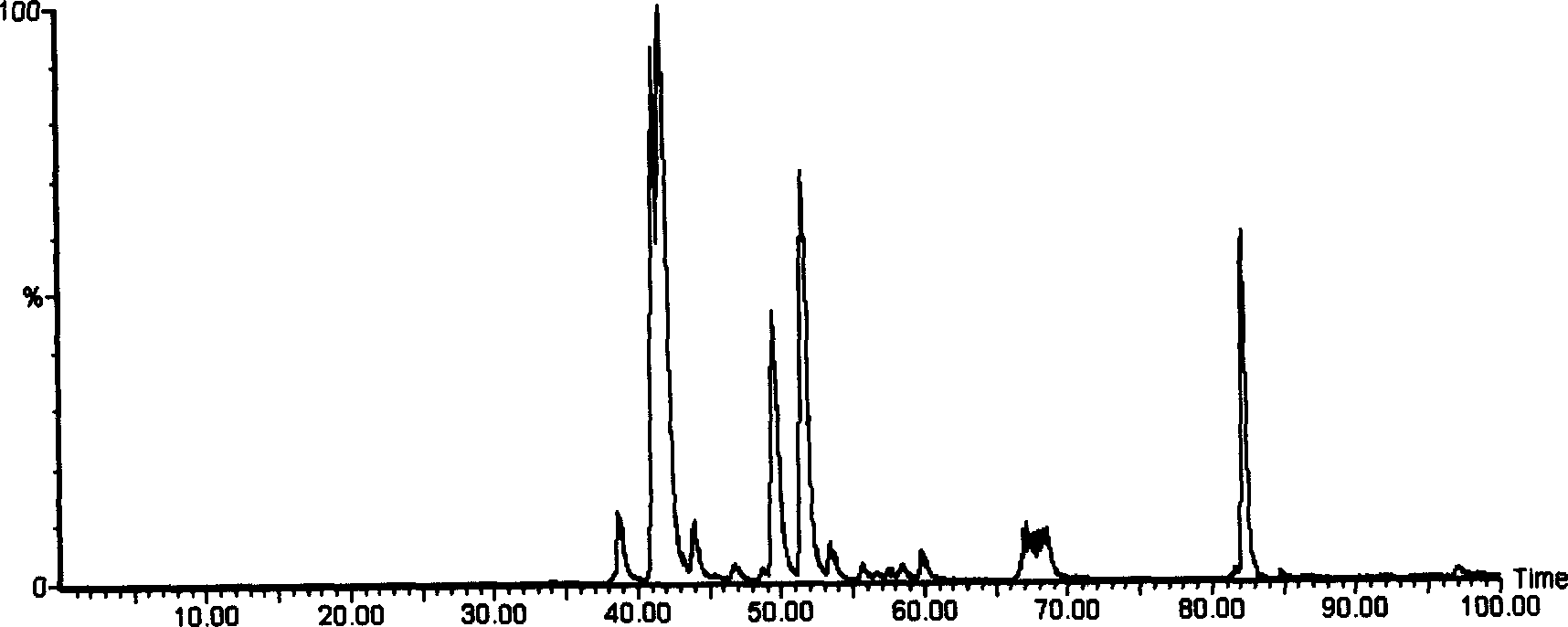

[0018] 1. Separation of trypsin lysate of myoglobin by reversed-phase capillary column

[0019] Instrument: Nano LC chromatographic system of Diane Company and Q-TOF Micro mass spectrometer of Micromass Company Capillary chromatographic column: 40cm×75μm i.d.; Chromatographic medium: C18 reverse phase chromatography filler, 3μm, 120 chromatographic conditions: mobile phase A, 2% acetonitrile aqueous solution +0.1% formic acid; mobile phase B, 20% acetonitrile aqueous solution +0.1% formic acid Flow rate, 0.2μl / min, detection wavelength, 214nm; linear gradient, 0-30min, 100%A-60%B; 30-35min, 60% B-100% B; 35-85min, 100%B-100%B, 85-90min, 100%B-100%A, 100%A extended to 100min.

[0020] Sample: trypsin hydrolyzate of myoglobin, the concentration is 5.6 pmol / μl; the loading volume, 5 μl. See attached chromatogram figure 2 .

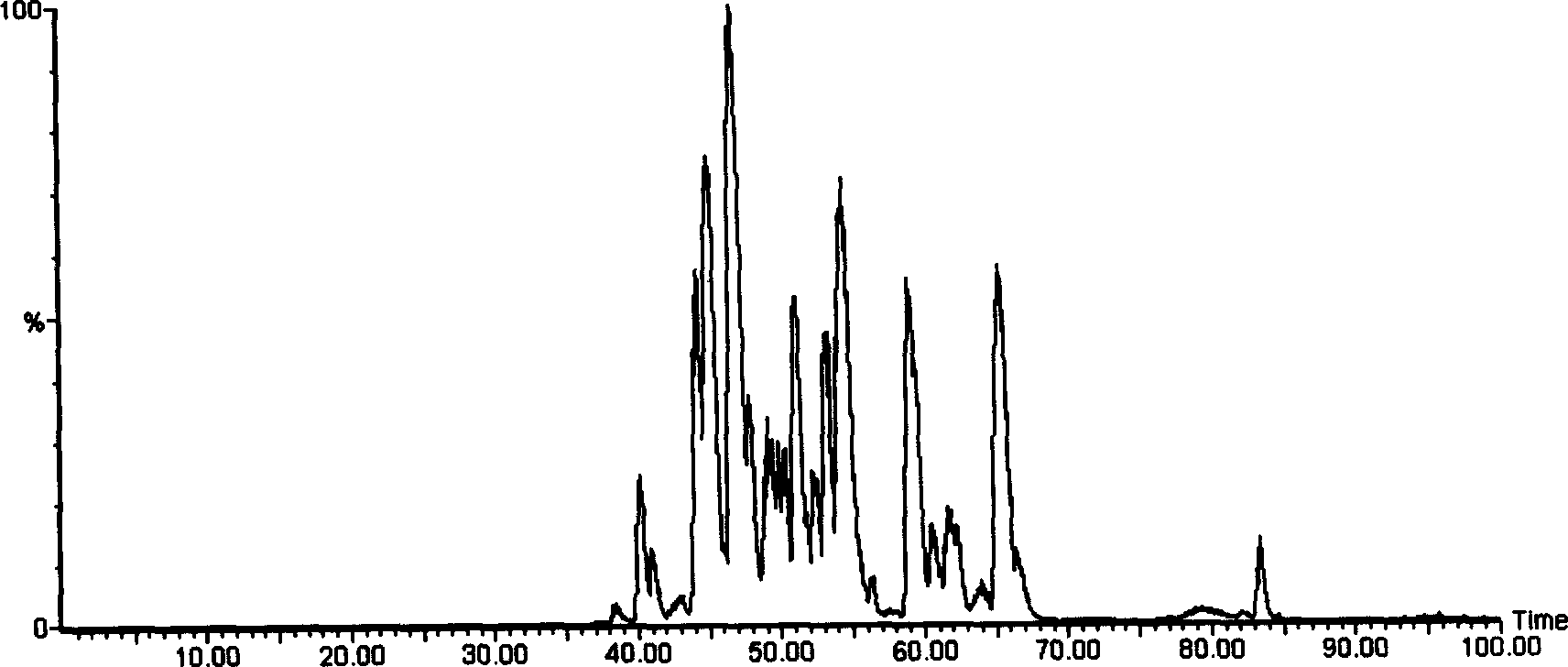

[0021] 2. Separation of plasma whole protein trypsin lysate by reversed-phase capillary column

[0022] Instrument: Nano LC chromatographic system of Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com