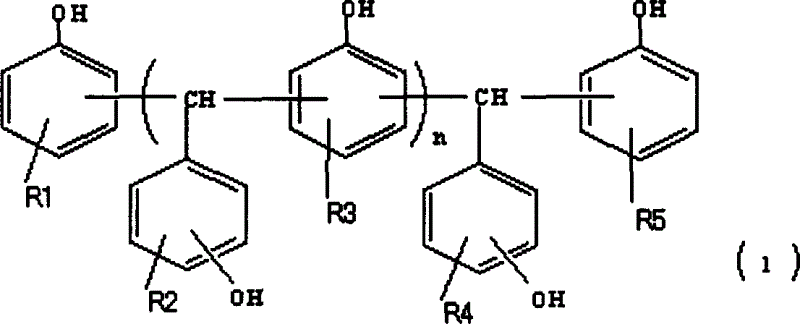

Epoxy resin compsn. and its application

A technology of epoxy resin and composition, applied in the direction of synthetic resin layered products, layered products, wood layered products, etc., can solve the problem that it cannot be made into varnish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

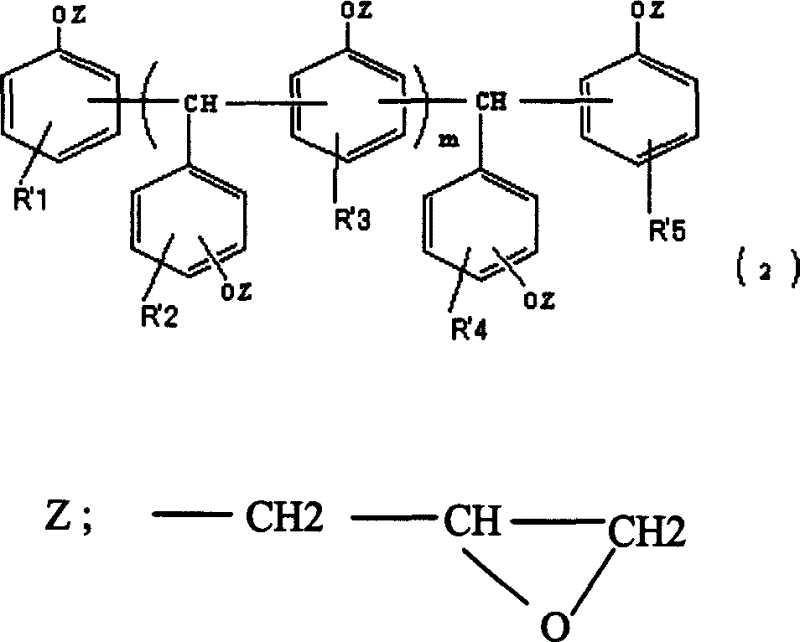

[0073] Synthesis Example of Epoxy Resin (EX-1)

[0074]Put 294 parts of triphenylmethane type phenolic resin (TPM-1) and 1388 parts of epichlorohydrin obtained in the synthesis example into a flask equipped with a thermometer, a cooling tube and a stirrer, and dissolve them under stirring. After heating up to 70 degreeC, 20 parts of tetramethylammonium chloride 20% aqueous solutions were added, and it stirred for further 3 hours. Then, 238 parts of 48% sodium hydroxide aqueous solutions were added separately over 90 minutes, and it was made to react further for 1 hour. After the reaction, excess epichlorohydrin, water and the like were distilled off under heating and pressure at 120°C. After adding 460 parts of xylene and 500 parts of water to the residue and washing with water, water was separated. Furthermore, the temperature of this xylene solution was raised to 70 degreeC, 25 parts of 48% sodium hydroxide aqueous solutions were added, and it was made to react for 2 hours...

Embodiment 2

[0076] Synthesis Example of Epoxy Resin (EX-3)

[0077] Synthesis was carried out in the same manner as epoxy resin synthesis example-1, except that the phenol resin obtained in triphenylmethane type phenol resin synthesis example (TPM-3) was used. The solid content of gained methyl ethyl ketone solution is 80.2% (weight), and epoxy group equivalent is 169g / eq (solid conversion value), and the content of m=0 is 62.0% (weight) (m=0.68), chromaticity is Gard The sodium color value is counted as 3. In addition, after storing the methyl ethyl ketone solution at 25° C. for 1 day, a heating cycle of storing at 7° C. for 1 day was performed as one cycle. As a result, no epoxy resin was precipitated even after 30 cycles.

Embodiment 4

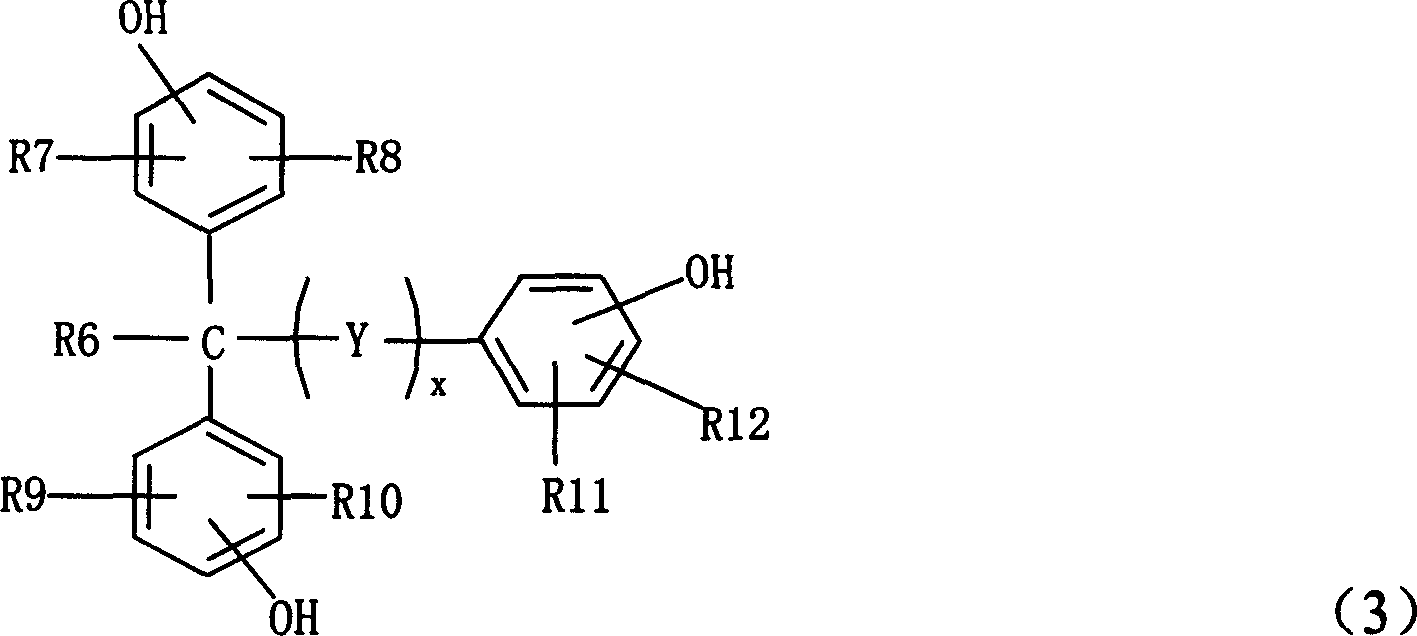

[0085] Synthesis Example of Epoxy Resin (EX-5)

[0086] In the flask that thermometer, cooling pipe, stirrer are equipped with, pack into 294 parts by the content rate of the phenolic resin of n=0 82.7% (weight), phenol content rate 0.8% (weight), hydroxyl equivalent is 98g / eq Triphenylmethane type phenolic resin (TPM-A) obtained from p-hydroxybenzaldehyde and phenol (n = 0.2, 4, 4', 4"-trihydroxyl (triphenylmethane) content = 58% by weight , 4,4', 2"-trihydroxyl (triphenylmethane) content: 33% (weight), 4,2', 2"-trihydroxyl (triphenylmethane) content: 9% (weight) ), 1388 parts of epichlorohydrin are dissolved under stirring. After being warmed up to 70°C, add 20 parts of tetramethylammonium chloride 20% aqueous solution, and further stir for 3 hours. After that, add 48% hydrogen separately through 90 minutes 238 parts of sodium oxide aqueous solution, and further reacted for 1 hour. After the reaction was completed, under heating and pressure at 120°C, excess epichlorohydrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com