Process for rolling deformation magnesium and magnesium alloy sheet material

A processing method and magnesium alloy technology, which is applied in the field of rolling processing of deformed magnesium and magnesium alloy plates, can solve the problems of low yield and difficulty in preparing large and thin-walled components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

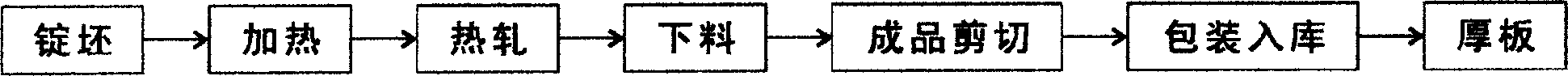

[0014] The rolling processing method of deformed magnesium and magnesium alloy plates. When rolling and processing thick plates, the continuously cast ingots are cut into 165×750×800MM ingots by face milling and placed in a soaking furnace. Tissue homogenization treatment, the soaking temperature is 400-420°C, the time is 22-26h, and then air-cooled to room temperature; then heated in a heating furnace for 6-8h, the temperature of the metal out of the furnace is 460-490°C; hot rolling is adopted, and the roll is Upper and lower concave rolls, concavity 0.15-0.30mm, preheating 2-8h, preheating temperature 120-160°C, hot rolling finishing temperature 370-430°C, rolling processing rate 70-94%, and according to the properties of the alloy Determine the hot-rolling temperature and the end-rolling temperature based on its plasticity diagram and other factors, and then cut and pack the finished product as required to make MB3 wrought magnesium and magnesium alloy thick plates in R sta...

Embodiment 2

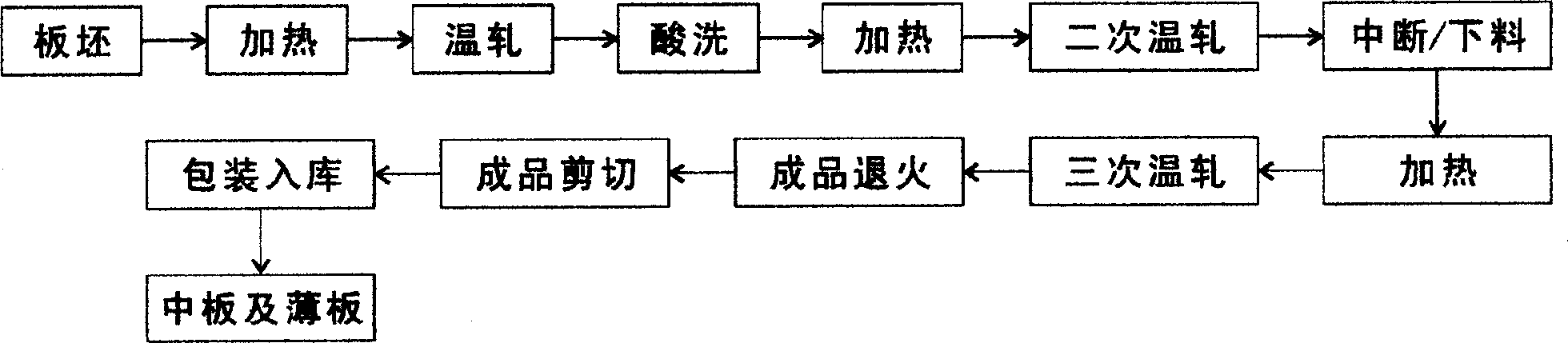

[0016] The rolling processing method of deformed magnesium and magnesium alloy plates, when implementing the rolling process of plates, will be rolled into 10×1150×1000mm slabs, heated by a heating furnace, the heating temperature is 400-460°C, and the heating time is 2.5- 5h; then through the rolling mill for several times of warm rolling, the roll is a flat roll, the roll temperature is 100-150°C, the preheating time is 2-8h, and the rolling processing rate is 30-60%; then annealed in an annealing furnace, according to different alloy grades Select the appropriate annealing temperature according to the state requirements, the annealing temperature for the M state is 330-350°C, the annealing temperature for the Y2 state is 285-300°C, and the annealing time is 0.5-1.5h; then the finished product is cut and packaged according to the requirements. , and prepare MB1 wrought magnesium and magnesium alloy middle plates with a thickness of 2-10mm in M state.

Embodiment 3

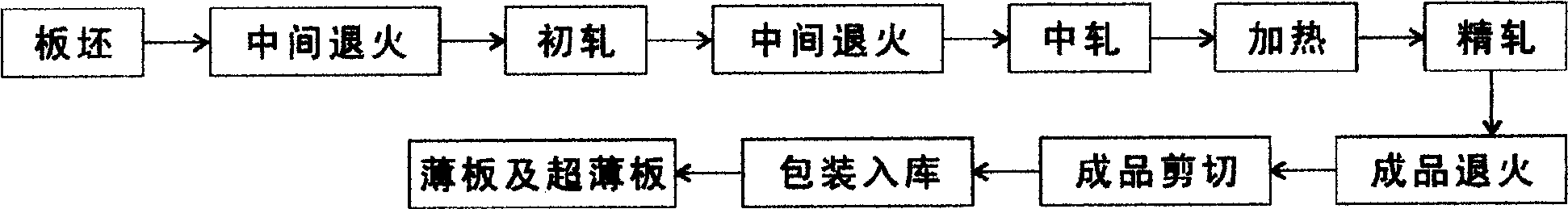

[0018] The rolling processing method of deformed magnesium and magnesium alloy plates. When rolling and processing thin plates, the slabs of 4×1150×2000mm are annealed in the middle, the annealing temperature is 420-450°C, and the annealing time is 2.0-2.5h. The rolling mill is warm rolled for many times, the rolls are upper and lower flat rolls, the roll preheating temperature is 90-120°C, the preheating time is 4-8h, the rolling temperature is 420-450°C, the rolling processing rate is 30-60%, and the rolling is 2 ×1150×1500mm, annealing again, the annealing temperature is 400-440℃, the annealing time is 1.5-2.0h, the rolling mill is warm rolled for many times, the rolls are upper and lower flat rolls, the preheating temperature of the rolls is 90-120℃, and the preheating time is 4-8h , the rolling temperature is 400-440°C, the rolling processing rate is 30-60%, and the finished product is annealed, and the appropriate annealing temperature is selected according to different a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com