Process for preparing rare-earth green long-lasting luminescent glass

A technology of long afterglow and glass, which is applied in the field of preparation of rare earth green long afterglow glass, which can solve the problems of narrow application range, single excitation source, complicated process, etc., and achieve the effect of long afterglow time, simple preparation method and bright afterglow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

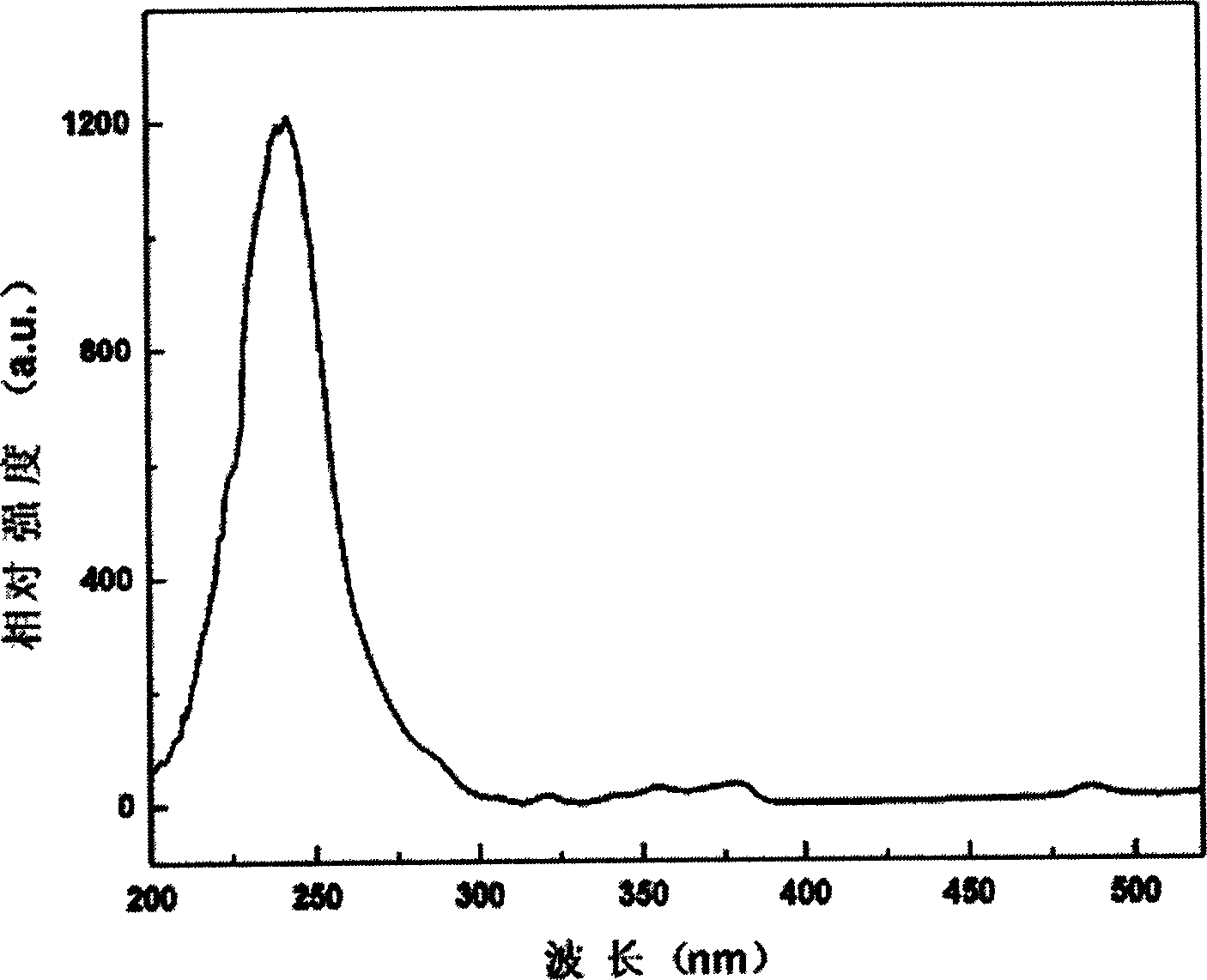

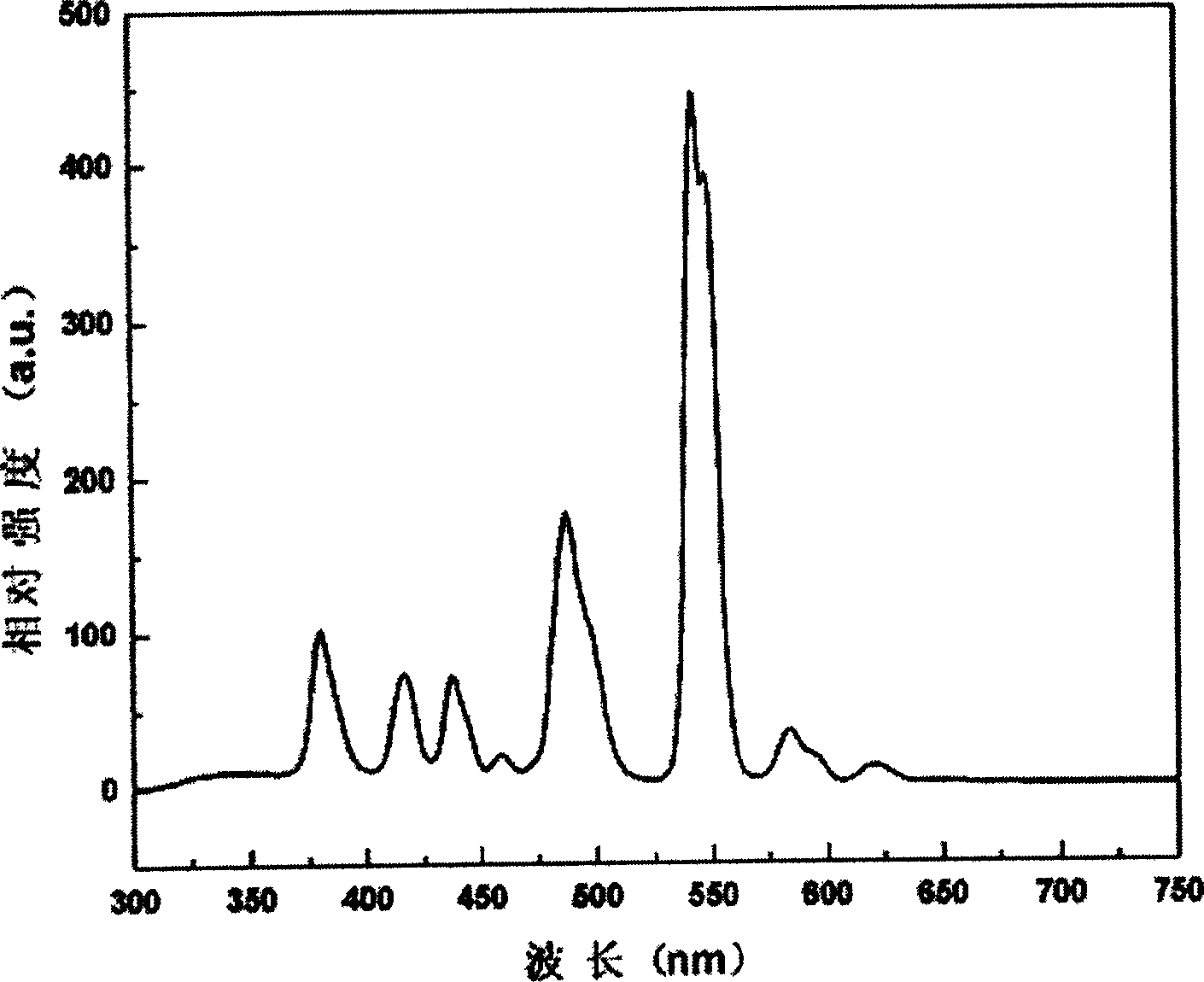

Embodiment 1

[0026] The molar percentage composition of the glass is: 5% lithium carbonate, 30% barium oxide, 5% aluminum oxide, 10% boron trioxide, 50% silicon dioxide, and 0.05% terbium oxide. After grinding and mixing the raw materials, put them into a crucible, keep the temperature at 1300°C for one hour in a high-temperature furnace, pour them into a preheated mold, anneal at 500°C for half an hour, and cool to room temperature to obtain a colorless and transparent long afterglow glass . After irradiating the glass with UV254nm ultraviolet lamp for half an hour, the glass emits a bright green long afterglow, and after 10 hours after stopping the excitation, the afterglow of the glass is still visible to the naked eye in the dark. After the afterglow disappears, irradiate the whole piece of glass with long-wave ultraviolet light with a wavelength of 366nm for 30 seconds. After removing the excitation light source, the green long afterglow of the glass reappears, that is, the long after...

Embodiment 2

[0028] The molar percentage composition of the glass is: 40% barium oxide, 10% aluminum oxide, 8% boron trioxide, 42% silicon dioxide, and 0.002% terbium oxide. After the raw materials are ground and mixed, put them into a crucible, keep the temperature at 1400°C for one hour in a high-temperature furnace, pour into a preheated mold, anneal at 550°C for one hour, and cool to room temperature to obtain a colorless and transparent long afterglow glass . After irradiating the glass with UV254nm ultraviolet lamp for half an hour, the glass emits a bright green long afterglow, and after 7 hours of stopping excitation, the afterglow of the glass is still visible to the naked eye in the dark. After the afterglow disappears, irradiate the whole piece of glass with a laser with a wavelength of 514nm for 20 seconds. After removing the laser, the green long afterglow of the glass reappears, that is, the long afterglow stimulated by light.

Embodiment 3

[0030] The molar percentage composition of the glass is: 20% barium oxide, 20% boron trioxide, 60% silicon dioxide, 0.3% terbium oxide, 0.05% samarium oxide. After the raw materials are ground and mixed, put them into a crucible, keep the temperature at 1400°C for one hour in a high-temperature furnace, pour into a preheated mold, anneal at 600°C for 3 hours, and cool to room temperature to obtain a colorless and transparent long afterglow glass . After irradiating the glass with UV254nm ultraviolet light for half an hour, the glass emits a bright green long afterglow, and after 9 hours after stopping the excitation, the afterglow of the glass is still visible to the naked eye in the dark. After the afterglow disappears, irradiate the whole piece of glass with long-wave ultraviolet light with a wavelength of 366nm for 30 seconds. After removing the excitation light source, the green long afterglow of the glass reappears, that is, the long afterglow of light excitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com