Antibacterial household paper and its making process

A technology for household paper and manufacturing process, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of loss, failure to achieve antibacterial effect, increase cost, etc., and achieve the effect of good sterilization and inhibition of bacterial reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

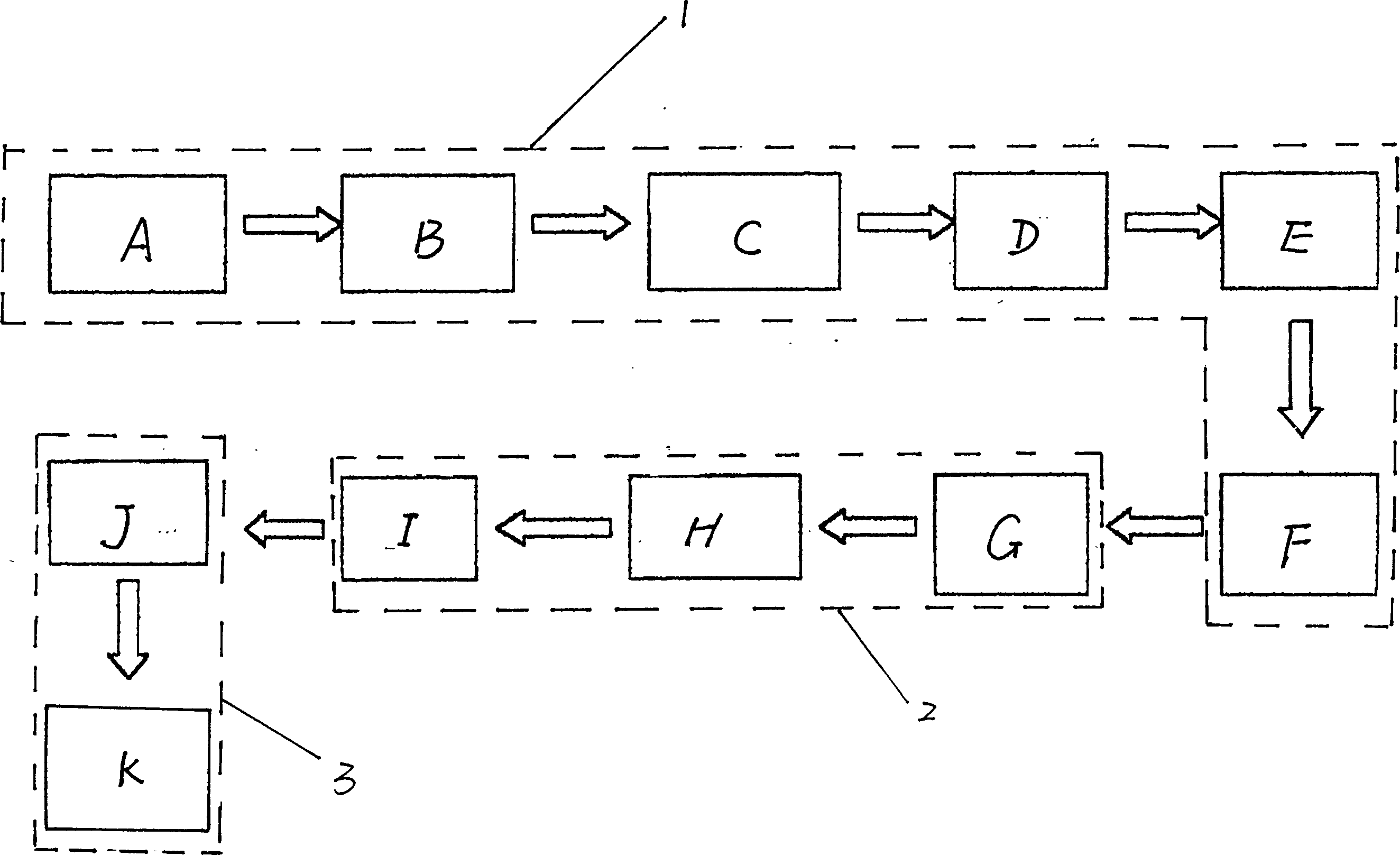

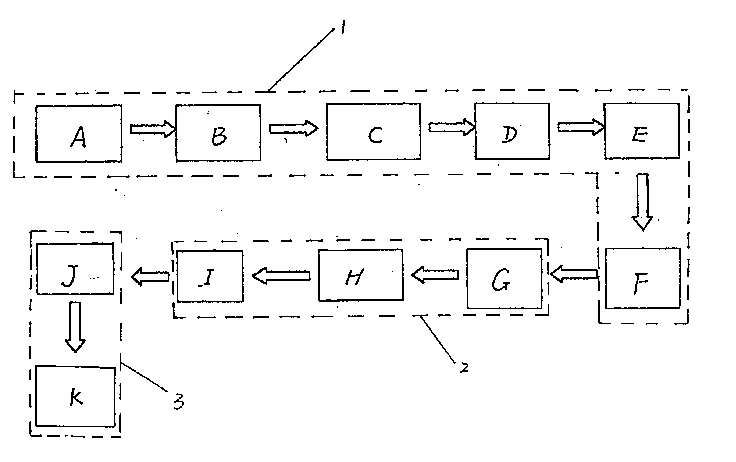

Method used

Image

Examples

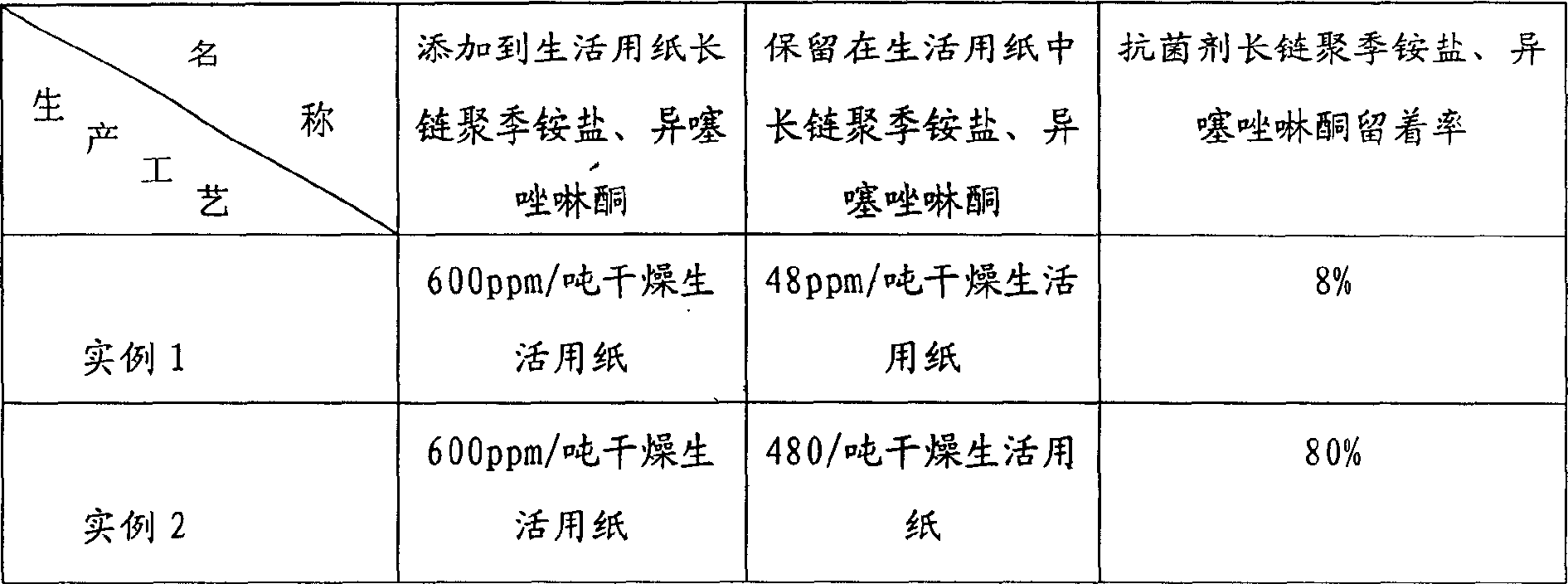

example 1

[0022] No retention aids are added, antibacterial agents and softeners are added to the pulping tank, and the pulp concentration in the refining tank during the pulping process is 4.5%:

[0023] 1. According to the volume of slurry mixing tank is 30m 3 , the concentration of the pulp after dilution is 3.3%, and the absolute dry pulp volume of each pool of pulp is calculated = 30 * 3.3% = 1.0 tons;

[0024] 2. Weigh 6kg of paper-based antibacterial additives (mainly composed of long-chain polyquaternium and isothiazolinone) produced by Hangzhou Xi’anda Antibacterial Technology Research Institute Co., Ltd. according to 0.6% dry pulp, add 80 times of water Dilute and stir evenly for later use;

[0025] 3. Weigh 3.6 kg of "Jinfang" softener produced by Unilever Co., Ltd. according to 0.3% of dry pulp, add 50 times of water, dilute and stir evenly for later use;

[0026] 4. Slowly add the solution in steps 2 and 3 into the pulp mixing tank filled with pulp, and after the pulp is ...

example 2

[0028] Add the retention aid, antibacterial agent and softener to the pulp mixing tank successively, and the pulp concentration in the pulping tank in the pulping process is 9%:

[0029] 1. According to the volume of the mixing tank is 30m 3 , the concentration of the pulp after dilution is 3.3%, and the absolute dry pulp volume of each pool of pulp is calculated = 30 * 3.3% = 1.0 tons;

[0030] 2. Weigh 6kg of paper-based antibacterial additives (mainly composed of long-chain polyquaternium and isothiazolinone) produced by Hangzhou Xianda Antibacterial Technology Research Institute Co., Ltd. according to 0.6% dry pulp, add 80 times of water Dilute and stir evenly for later use;

[0031] 3. Weigh 3.6 kg of "Jinfang" softener produced by Unilever Co., Ltd. according to 0.3% of absolute dry pulp, add 50 times of water, dilute and stir evenly for later use;

[0032] 4. Weigh 6kg of retention aid powdered polyacrylamide according to 0.5% of absolute dry pulp, add 100 times of cl...

example 3

[0035] In the online papermaking process, the retention aid is continuously added to the white water tank, and the antibacterial agent and softener are continuously added to the high level tank. The pulp concentration in the refining tank in the pulping process is 9%:

[0036] 1. According to the speed of the paper machine (160m / mim) and the weight of the paper produced (16g / m 2 ) and width (1.9m) and crepe rate (70%), it can be calculated that the paper output in 8 hours = 160m / min × 16g / m 2 ×1.9m×60 minutes×8×0.7÷1000=1634 kg base paper;

[0037] 2. Take by weighing 6.54 kilograms of Lobenqing (main component is benzalkonium chloride) and 6.54 kilograms of glutaraldehyde produced by Canada Loster Co., Ltd. by 0.4% of dry paper weight, add 100 times of clear water to dilute and stir evenly, Put it in the metering tank for use;

[0038] 3. Weigh 5 kg of "Langqi" softener produced by Procter & Gamble Company according to 0.3% of the weight of dry paper, add 100 times of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com