Konjaku gluocomannan-calcium alginate microball for carrying medicine and preparing method

A technology of konjac glucomannan and calcium alginate, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, block delivery, etc., to achieve the effect of convenient and sustained release, simple preparation process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

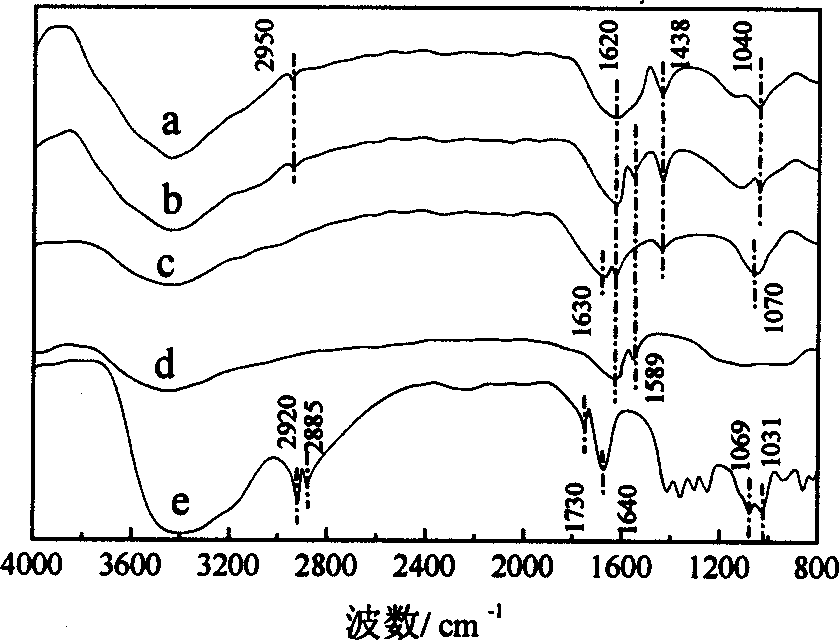

[0020] Dissolve 2g sodium alginate in 100ml deionized water or dissolve 2g sodium alginate and 0.5g konjac glucomannan in 100ml deionized water, drop sodium alginate sol or mixed sol in the form of tiny droplets into the concentration of 0.2M Calcium alginate microspheres or konjac glucomannan-calcium alginate microspheres with smooth surface, uniform particle size and good sphericity ( figure 1 ). From the infrared absorption curve of konjac glucomannan-calcium alginate microspheres, it can be found that due to the weak hydrogen bond and electrostatic interaction between alginic acid and konjac glucomannan, Some absorption peaks in the curve disappeared or some new absorption peaks appeared ( figure 2 ).

example 2

[0022] Dissolve 2g sodium alginate and 0.5g konjac glucomannan in 100ml deionized water, drop the mixed sol into 0.2M CaCl in the form of tiny droplets 2 in water or CaCl 2 Concentration is 0.2M, chitosan concentration is 0.5% (w / v), chitosan molecular weight is 8.55×10 6 Calcium alginate-chitosan microspheres or konjac glucomannan-calcium alginate- Chitosan microspheres. From the infrared absorption curve of konjac glucomannan-calcium alginate-chitosan microspheres ( figure 2 ), most of the absorption peaks became weaker, which was mainly due to the multiple interactions between alginic acid, konjac glucomannan and chitosan. In addition, the structure of the microsphere gel without adding konjac glucomannan and adding konjac glucomannan was significantly different ( image 3 , Figure 4 ), which is mainly due to the filling of konjac glucomannan and the multiple interactions between alginic acid, konjac glucomannan and chitosan.

example 3

[0024] Dissolve 2g sodium alginate and 0.5g konjac glucomannan in 100ml deionized water, drop the mixed sol into CaCl in the form of tiny droplets 2 The concentration is 0.2M, the chitosan concentration is 0.25% (w / v), and the molecular weight is 5.87×10 6 in the chitosan calcium chloride solution, gel for 30 minutes, filter and wash, and konjac glucomannan-calcium alginate-chitosan microspheres with a smaller molecular weight of chitosan can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com