Tin zinc copper leadless solder alloy

A lead-free solder and alloy technology, applied in metal processing equipment, welding/cutting media/materials, welding media, etc., to achieve excellent structural stability, low price, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

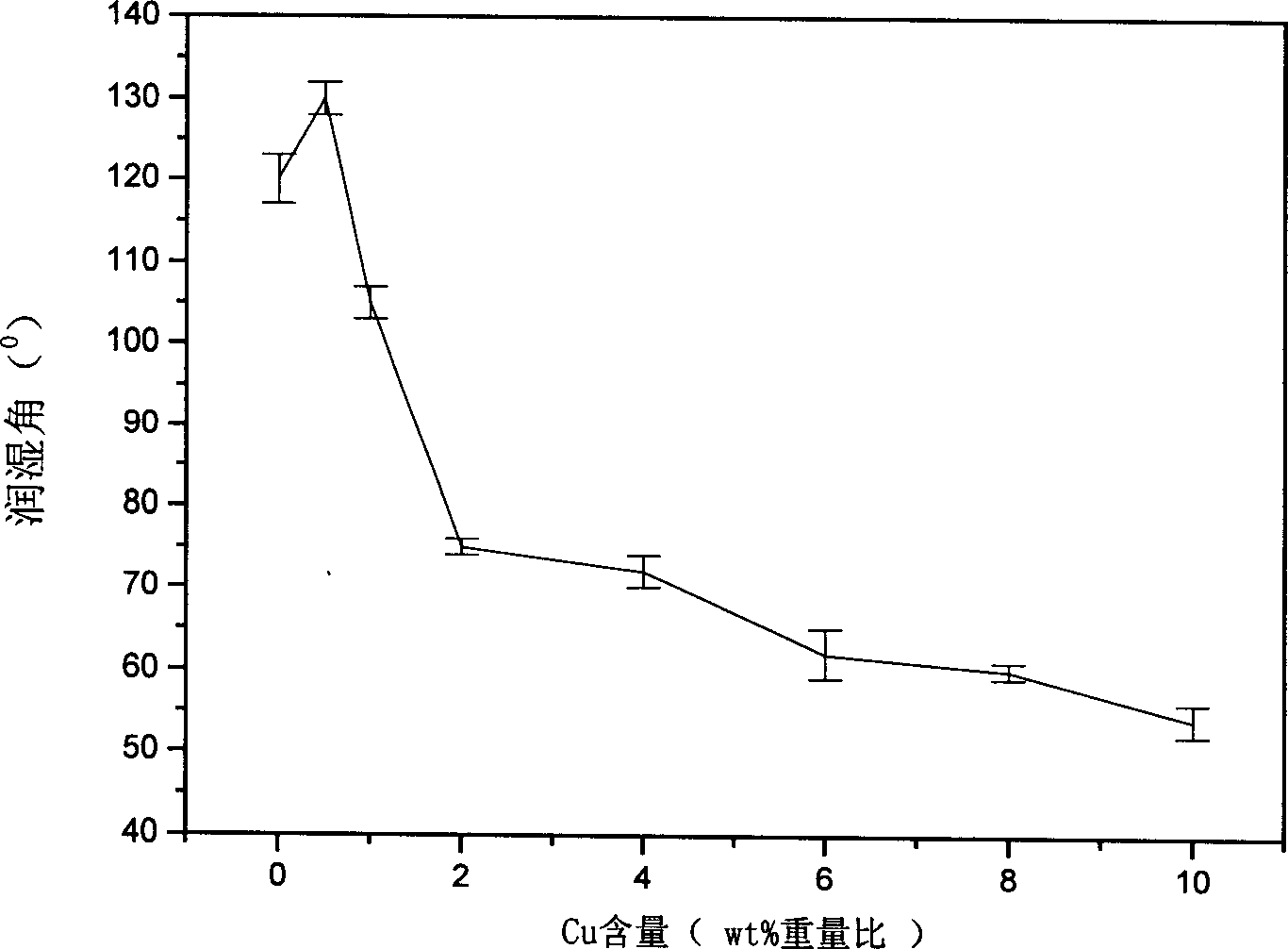

Image

Examples

Embodiment

[0023] The following chemical composition (%) is selected: (7-9) Zn; (0.05-0.15) RE; (0.5-2) Bi; (4-6) Cu, and the balance is Sn. The above-mentioned raw materials prepared according to the composition are put into an industrial vacuum induction furnace for smelting. Under normal pressure, the temperature is kept at 600°C for 4 to 6 hours, and then the solder alloy can be obtained by pouring. The brazing powder is prepared by spraying, and the brazing flux is added. , the solder paste is obtained. Can be used for reflow soldering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com