Silicon photoelectric probe compatible with deep submicron radio frequency technology

A deep submicron, silicon photoelectric technology, applied in photometry, electrical solid-state devices, optical radiation measurement, etc., can solve problems such as limiting the range of optical fiber coupling activities, large parasitic capacitance, etc., to achieve high yield, improve performance, and high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

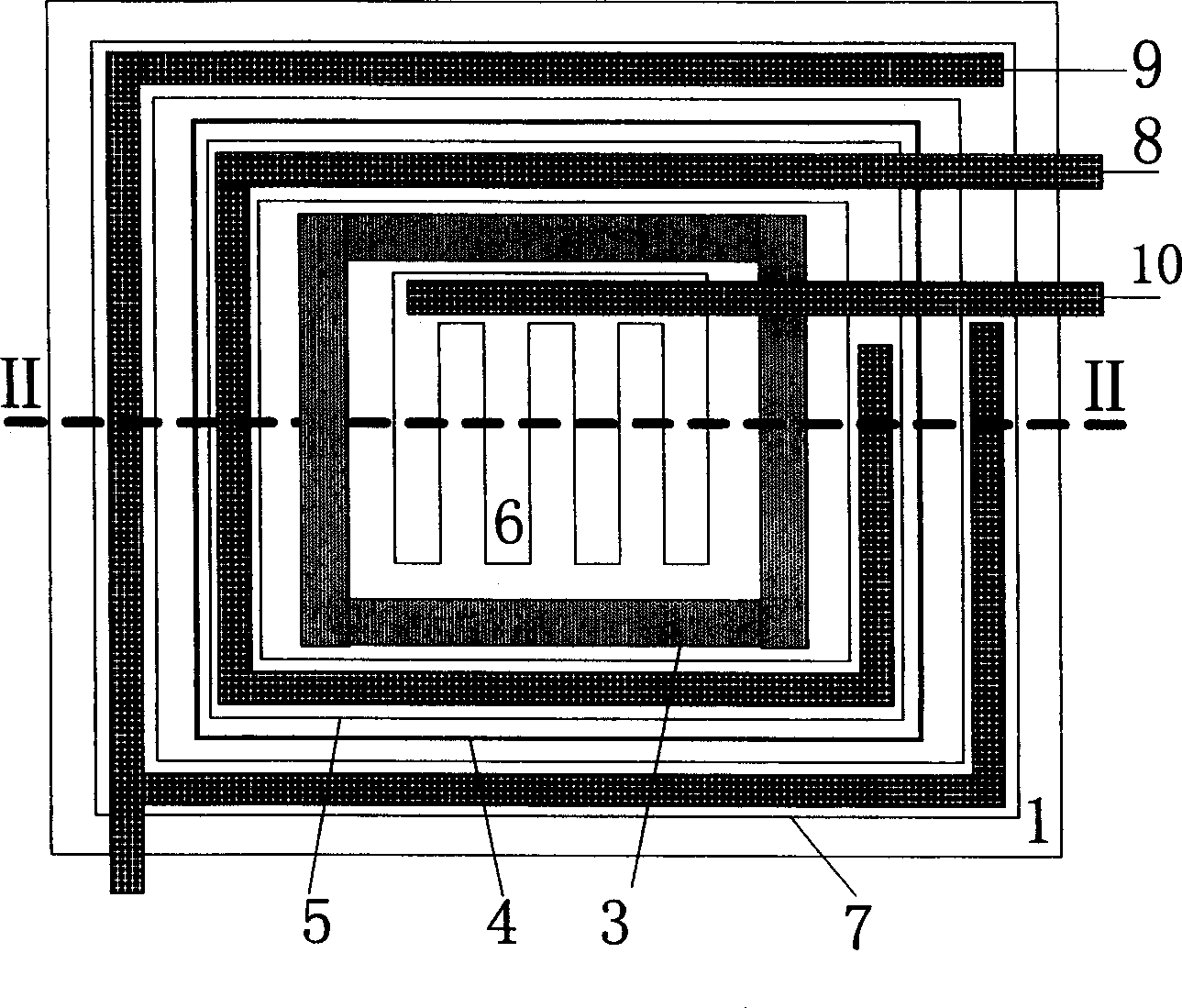

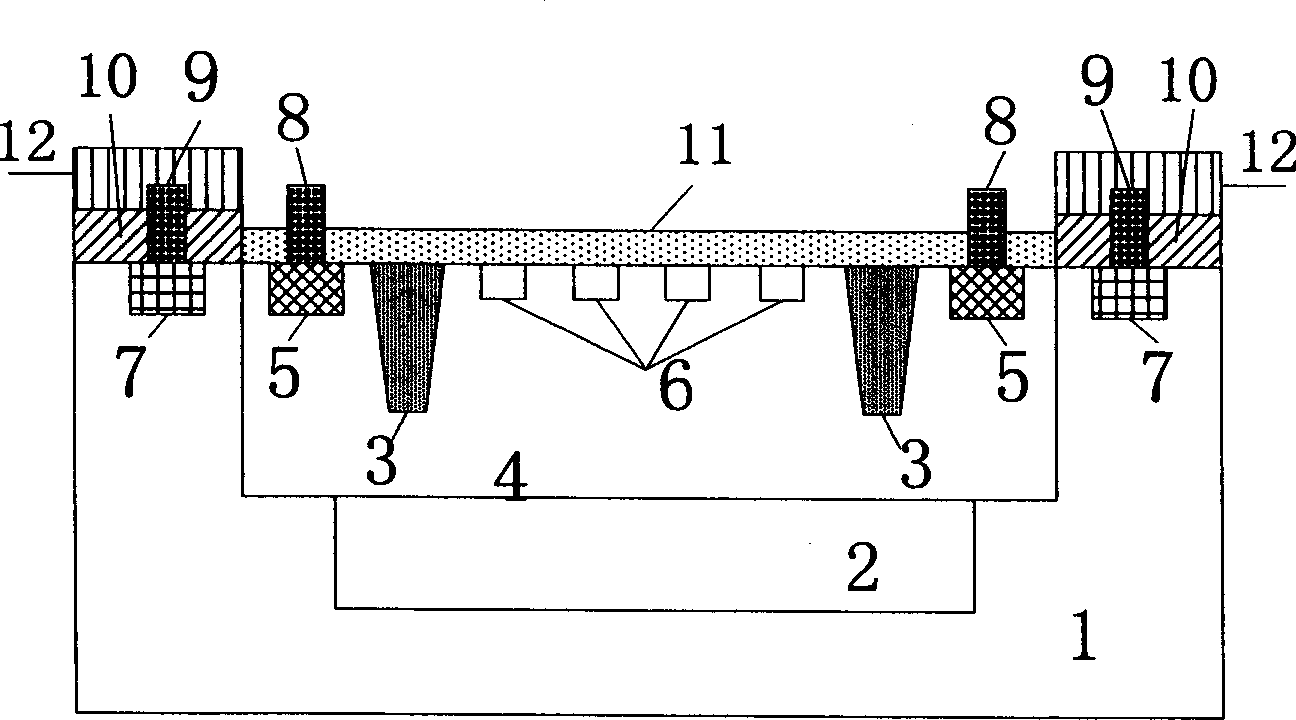

[0015] The present invention is achieved by the following methods: figure 1 Shows the layout structure of the photodetector for fabrication on deep submicron RF_CMOS process, figure 2 A longitudinal cross-sectional structure diagram of the photodetector is shown, mainly showing the longitudinal dimension of the photodetector.

[0016] P-type semiconductor substrate 1, deep n-type well 2, the deep n-type well 2 is fabricated in the substrate 1; n-type well 4, the n-type well 4 is fabricated on the substrate 1; shallow trench isolation region 3 , the shallow trench isolation region 3 is fabricated in the n-type well 4; four interdigitated P+ type diffusion regions 4, the four interdigitated P+ + Type diffusion region 6 is set on n-type well 4; P + Type guard ring 7, the P + type guard ring 7 is fabricated on the substrate 1 and around the n-type well 4; the anti-reflection coating layer 11 is deposited on four interdigitated P + Type diffusion region 6 above; by the interdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com