Elastic body lamp buoy

A technology of elastic and body lights, which is applied in the direction of buoys, special-purpose ships, warships, etc., can solve the problems of high follow-up cost, long maintenance-free time, low maintenance cost, etc., achieve excellent physical properties and processing performance, and long maintenance-free time , low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

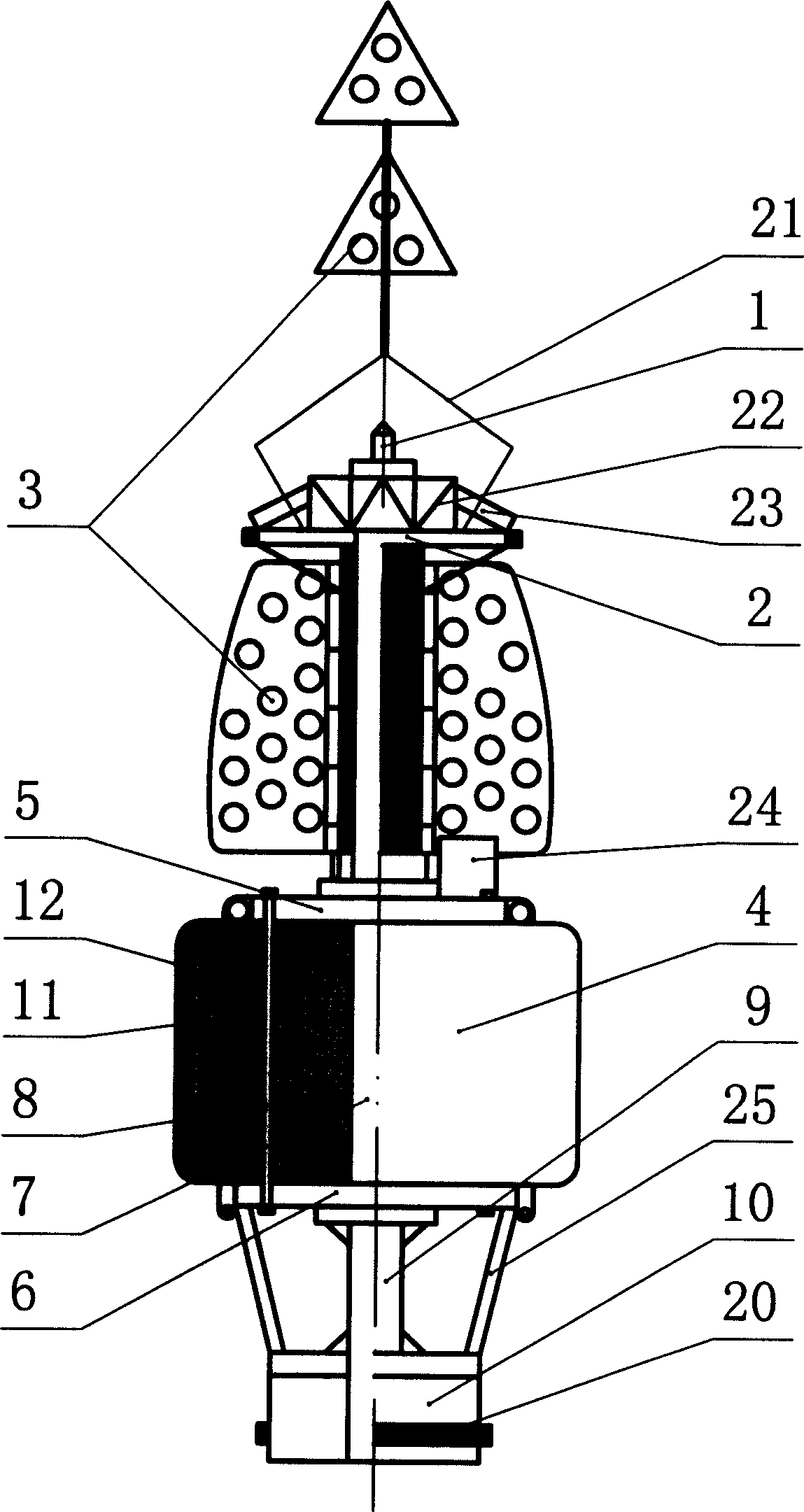

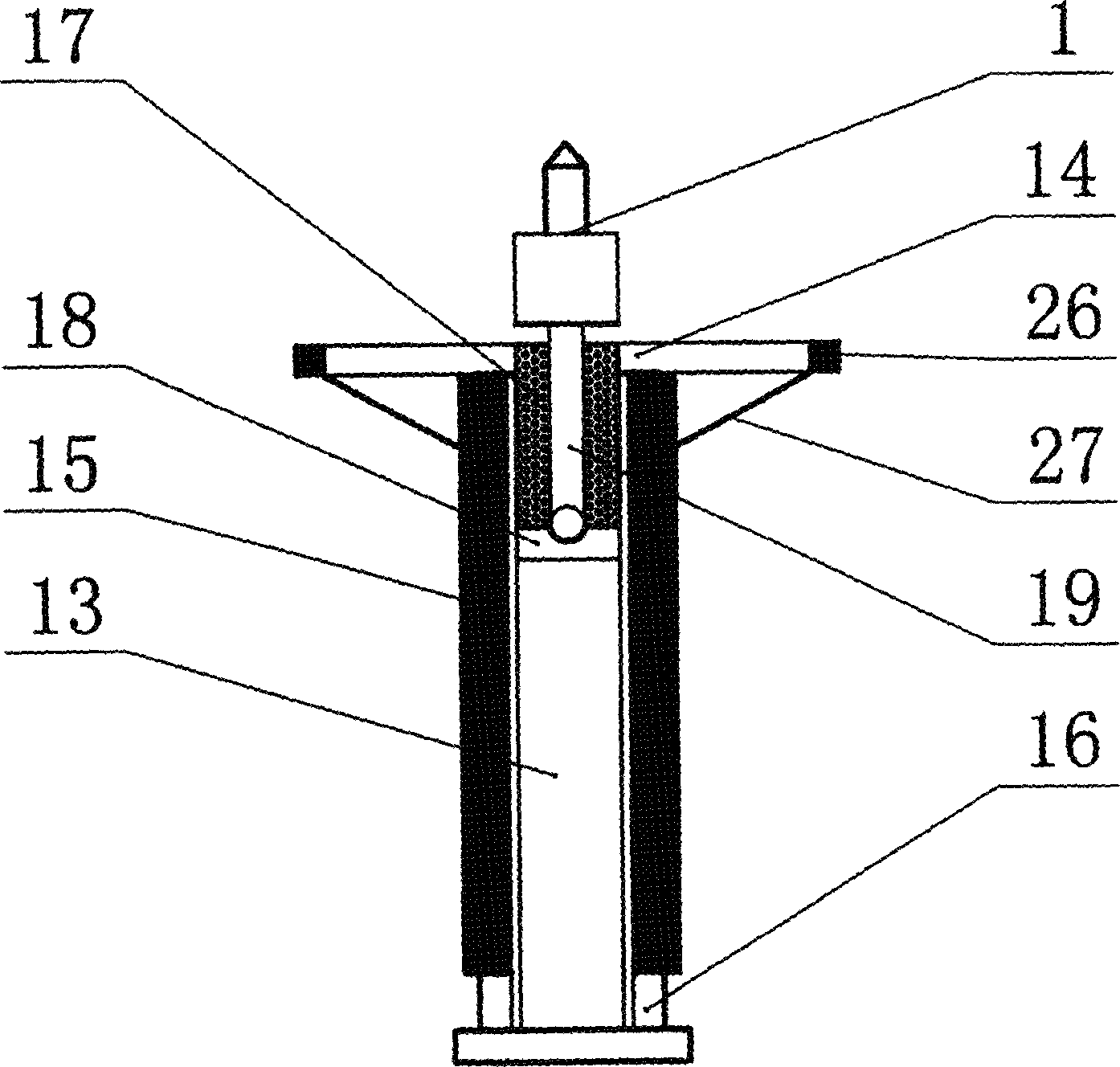

[0021] An elastic body light buoy, which includes a signal light 1, a light frame 2, a daily mark 3, a floating body 4, an upper cover plate 5, a lower support plate 6, a central tube 7, 8 connecting rods 8, a tail tube 9, and a counterweight 10 . The signal lamp 1 is arranged on the upper part of the lamp holder 2, the lower end of the lamp holder 2 is fixedly connected with the upper cover plate 5, the upper cover plate 5 is arranged on the upper part of the floating body 4, and the lower supporting plate 6 is arranged at the lower part of the floating body 4, the upper cover plate 5, the lower supporting plate 6 and the floating body 4 are connected as a whole through the central pipe 7 and the connecting rod 8, and the upper end of the tail pipe 9 It is fixedly connected with the lower supporting plate 6 , and its lower end is fixedly connected with the counterweight 10 . A lampshade 21 can be arranged on the upper part of the signal lamp 1, a radar reflector 22 and a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com