Preparation of B4C hard alloy material by machanochemistry process

A mechanochemical method and cemented carbide technology, which is applied in the fields of mechanical alloying and alloy material preparation, can solve the problems of increased pressure in closed tanks, difficult chemical reactions, difficult chemical reactions, etc., and achieves easy separation, low cost, and high technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] xxx tool factory, producing WC cemented carbide, all is to adopt sintering method for many years, and process is complicated, and cost is high, and quality is uneven, adopts the method of the present invention to prepare B 4 C cemented carbide material, its raw material weight percentage wt% is B 2 o 3 60%, C 40%, Mg powder and B 2 o 3 The weight ratio of 0.0, the preparation process steps are as follows:

[0016] The first step is to prepare materials

[0017] Weigh B 2 o 3 9kg, C 6kg spare, the largest diameter of the powder B 2 o 3 is 3mm, and C is 2.5mm;

[0018] The second step, canning

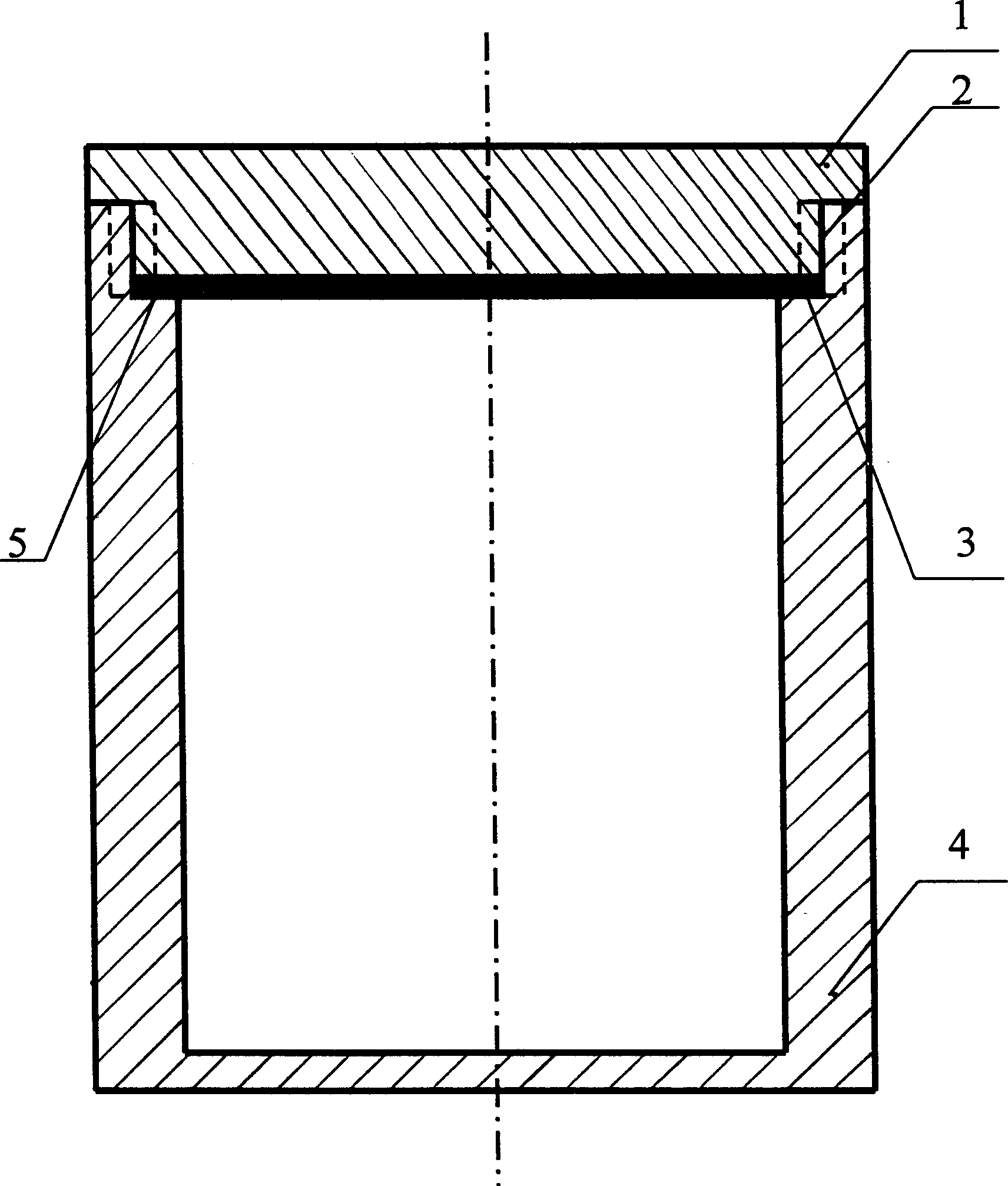

[0019] Will have been weighed B 2 o 3 Put them together with the respective values of C into a grinding tank that can hold 200kg of ingredients; add 45kg of φ30mm steel balls to the tank, then cover the grinding tank cover [1] on the grinding tank body [4], and A porous medium gasket [3] with an average pore diameter of 50 μm is added to the inner platform [5] of t...

Embodiment 2

[0028] xxx tool factory used the self-manifestation method in the past to produce cemented carbide turning tools. Due to the high cost and complicated operation, the present invention is used to produce B 4The technical scheme of C, the ratio of raw materials used is B 2 o 3 79%, C is 21%, Mg and B 2 o 3 The weight ratio of is 0.353, prepare B by the following steps 4 C carbide material:

[0029] The first step is to prepare materials

[0030] Weigh B 2 o 3 11.85kg, C 3.15kg, Mg 4.18kg, the maximum diameter of the powder or grain of each component is 2.5mm;

[0031] The second step, canning

[0032] Will have been weighed B 2 o 3 , C and Mg respectively, put them into a grinding tank that can hold 200kg of ingredients; then add 57.5 kg of φ30mm steel balls to the tank, and then place a porous media gasket with an average pore size of 80 μm [3] to place the The lid of the grinding tank [1] is covered on the grinding tank body [4] and pressed tightly;

[0033] The t...

Embodiment 3

[0041] xxx unit, change production to prepare B with mechanochemical method proposed by the present invention 4 C cemented carbide material, raw material composition ratio is B 2 o 3 92wt%, C is 8wt%, Mg and B 2 o 3 The weight ratio is 1.1, and the steps are as follows:

[0042] The first step is to prepare materials

[0043] According to the design weight percentage wt%, weigh B 2 o 3 7.36kg, C 0.64kg, Mg 8.096kg, the maximum diameter of the powder is 2mm

[0044] The second step, canning

[0045] Will have been weighed B 2 o 3 , C and Mg, put them together into a grinding tank that can hold 200kg of ingredients; then add 48kg of φ30mm steel balls to the tank, and then put a porous medium gasket [3] with an average pore diameter of 100μm on the On the inner platform [5] of the grinding tank body, cover the grinding tank cover [1] and press it tightly;

[0046] The third step is to place the grinding tank on the tank seat of the vibration ball mill and lock it;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com